Heat transfer coefficient

The heat transfer coefficient or film coefficient, in thermodynamics and in mechanical and chemical engineering, is the proportionality coefficient between the heat flux and the thermodynamic driving force for the flow of heat (i.e., the temperature difference, ΔT):

where

- q : heat flux, W/m2 i.e., thermal power per unit area, q = dQ/dA

- h : heat transfer coefficient, W/(m2•K)

- ΔT : difference in temperature between the solid surface and surrounding fluid area, K

It is used in calculating the heat transfer, typically by convection or phase transition between a fluid and a solid.

The heat transfer coefficient has SI units in watts per squared meter kelvin: W/(m2K).

Heat transfer coefficient is the inverse of thermal insulance. This is used for building materials (R-value) and for clothing insulation.

There are numerous methods for calculating the heat transfer coefficient in different heat transfer modes, different fluids, flow regimes, and under different thermohydraulic conditions. Often it can be estimated by dividing the thermal conductivity of the convection fluid by a length scale. The heat transfer coefficient is often calculated from the Nusselt number (a dimensionless number). There are also online calculators available specifically for heat transfer fluid applications.

Composition

A simple method for determining an overall heat transfer coefficient that is useful to find the heat transfer between simple elements such as walls in buildings or across heat exchangers is shown below. Note that this method only accounts for conduction within materials, it does not take into account heat transfer through methods such as radiation. The method is as follows:

Where:

-

= the overall heat transfer coefficient (W/(m2•K))

= the overall heat transfer coefficient (W/(m2•K)) -

= the contact area for each fluid side (m2) (with

= the contact area for each fluid side (m2) (with  and

and  expressing either surface)

expressing either surface) -

= the thermal conductivity of the material (W/(m·K))

= the thermal conductivity of the material (W/(m·K)) -

= the individual convection heat transfer coefficient for each fluid (W/(m2•K))

= the individual convection heat transfer coefficient for each fluid (W/(m2•K)) -

= the wall thickness (m)

= the wall thickness (m)

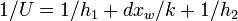

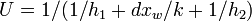

As the areas for each surface approach being equal the equation can be written as the transfer coefficient per unit area as shown below:

or

NOTE: Often the value for  is referred to as the difference of two radii where the inner and outer radii are used to define the thickness of a pipe carrying a fluid, however, this figure may also be considered as a wall thickness in a flat plate transfer mechanism or other common flat surfaces such as a wall in a building when the area difference between each edge of the transmission surface approaches zero.

is referred to as the difference of two radii where the inner and outer radii are used to define the thickness of a pipe carrying a fluid, however, this figure may also be considered as a wall thickness in a flat plate transfer mechanism or other common flat surfaces such as a wall in a building when the area difference between each edge of the transmission surface approaches zero.

In the walls of buildings the above formula can be used to derive the formula commonly used to calculate the heat through building components. Architects and engineers call the resulting values either the U-Value or the R-Value of a construction assembly like a wall. Each type of value (R or U) are related as the inverse of each other such that R-Value = 1/U-Value and both are more fully understood through the concept of an overall heat transfer coefficient described in lower section of this document.

Convective heat transfer Correlations

Although convective heat transfer can be derived analytically through dimensional analysis, exact analysis of the boundary layer, approximate integral analysis of the boundary layer and analogies between energy and momentum transfer, these analytic approaches may not offer practical solutions to all problems when there are no mathematical models applicable. As such, many correlations were developed by various authors to estimate the convective heat transfer coefficient in various cases including natural convection, forced convection for internal flow and forced convection for external flow. These empirical correlations are presented for their particular geometry and flow conditions. As the fluid properties are temperature dependent, they are evaluated at the film temperature  , which is the average of the surface

, which is the average of the surface  and the surrounding bulk temperature,

and the surrounding bulk temperature,  .

.

External flow, Vertical plane

Churchill and Chu correlation[1] for natural convection adjacent to vertical planes. NuL applies to all fluids for both laminar and turbulent flows. L is the characteristic length with respect to the direction of gravity, and RaL is the Rayleigh Number with respect to this length.

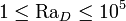

For laminar flows in the range of  , the following equation can be further improved.

, the following equation can be further improved.

External flow, Vertical cylinders

For cylinders with their axes vertical, the expressions for plane surfaces can be used provided the curvature effect is not too significant. This represents the limit where boundary layer thickness is small relative to cylinder diameter D. The correlations for vertical plane walls can be used when

where  is the Grashof number.

is the Grashof number.

External flow, Horizontal plates

W.H. McAdams [1] suggested the following correlations. The induced buoyancy will be different depending upon whether the hot surface is facing up or down. For a hot surface facing up or a cold surface facing down,

For a hot surface facing down or a cold surface facing up,

The length is the ratio of the plate surface area to perimeter. If the plane surface is inclined at an angle θ, the equations for vertical plane by Churchill and Chu may be used for θ up to  . When boundary layer flow is laminar, the gravitational constant g is replaced with g cosθ for calculating the Ra in the equation for laminar flow

. When boundary layer flow is laminar, the gravitational constant g is replaced with g cosθ for calculating the Ra in the equation for laminar flow

External flow, Horizontal cylinder

For cylinders of sufficient length and negligible end effects, Churchill and Chu has the following correlation for

External flow, Spheres

For spheres, T. Yuge [1] has the following correlation. for Pr≃1 and

Forced convection

Internal flow, Laminar flow

Sieder and Tate [1] has the following correlation for laminar flow in tubes where D is the internal diameter, μ_b is the fluid viscosity at the bulk mean temperature, μ_w is the viscosity at the tube wall surface temperature.

Internal flow, Turbulent flow

The Dittus-Bölter correlation (1930) is a common and particularly simple correlation useful for many applications. This correlation is applicable when forced convection is the only mode of heat transfer; i.e., there is no boiling, condensation, significant radiation, etc. The accuracy of this correlation is anticipated to be ±15%.

For a fluid flowing in a straight circular pipe with a Reynolds number between 10 000 and 120 000 (in the turbulent pipe flow range), when the fluid's Prandtl number is between 0.7 and 120, for a location far from the pipe entrance (more than 10 pipe diameters; more than 50 diameters according to many authors[2]) or other flow disturbances, and when the pipe surface is hydraulically smooth, the heat transfer coefficient between the bulk of the fluid and the pipe surface can be expressed explicitely as:

which can be simplified to give:

where

hydraulic diameter

hydraulic diameter - thermal conductivity of the bulk fluid

- thermal conductivity of the bulk fluid viscosity

viscosity mass flux

mass flux isobaric heat capacity

isobaric heat capacity- n = 0.4 for heating (wall hotter than the bulk fluid) and 0.33 for cooling (wall cooler than the bulk fluid).[3]

The fluid properties necessary for the application of this equation are evaluated at the bulk temperature thus avoiding iteration

Forced convection, External flow

In analyzing the heat transfer associated with the flow past the exterior surface of a solid, the situation is complicated by phenomena such as boundary layer separation. Various authors have correlated charts and graphs for different geometries and flow conditions. For Flow parallel to a Plane Surface, where x is the distance from the edge and L is the height of the boundary layer, a mean Nusselt number can be calculated using the Colburn analogy.[1]

Thom correlation

There exist simple fluid-specific correlations for heat transfer coefficient in boiling. The Thom correlation is for flow boiling of water (subcooled or saturated at pressures up to about 20 MPa) under conditions where the nucleate boiling contribution predominates over forced convection. This correlation is useful for rough estimation of expected temperature difference given the heat flux:[4]

where:

is the wall temperature elevation above the saturation temperature, K

is the wall temperature elevation above the saturation temperature, K- q is the heat flux, MW/m2

- P is the pressure of water, MPa

Note that this empirical correlation is specific to the units given.

Heat transfer coefficient of pipe wall

The resistance to the flow of heat by the material of pipe wall can be expressed as a "heat transfer coefficient of the pipe wall". However, one needs to select if the heat flux is based on the pipe inner or the outer diameter.

where k is the effective thermal conductivity of the wall material and x is the wall thickness.

If the above assumption does not hold, then the wall heat transfer coefficient can be calculated using the following expression:

where di and do are the inner and outer diameters of the pipe, respectively.

The thermal conductivity of the tube material usually depends on temperature; the mean thermal conductivity is often used.

Combining heat transfer coefficients

For two or more heat transfer processes acting in parallel, heat transfer coefficients simply add:

For two or more heat transfer processes connected in series, heat transfer coefficients add inversely:[5]

For example, consider a pipe with a fluid flowing inside. The rate of heat transfer between the bulk of the fluid inside the pipe and the pipe external surface is:

where

- q = heat transfer rate (W)

- h = heat transfer coefficient (W/(m2·K))

- t = wall thickness (m)

- k = wall thermal conductivity (W/m·K)

- A = area (m2)

= difference in temperature.

= difference in temperature.

Overall heat transfer coefficient

The overall heat transfer coefficient  is a measure of the overall ability of a series of conductive and convective barriers to transfer heat. It is commonly applied to the calculation of heat transfer in heat exchangers, but can be applied equally well to other problems.

is a measure of the overall ability of a series of conductive and convective barriers to transfer heat. It is commonly applied to the calculation of heat transfer in heat exchangers, but can be applied equally well to other problems.

For the case of a heat exchanger,  can be used to determine the total heat transfer between the two streams in the heat exchanger by the following relationship:

can be used to determine the total heat transfer between the two streams in the heat exchanger by the following relationship:

where

= heat transfer rate (W)

= heat transfer rate (W) = overall heat transfer coefficient (W/(m²·K))

= overall heat transfer coefficient (W/(m²·K)) = heat transfer surface area (m2)

= heat transfer surface area (m2) = log mean temperature difference (K)

= log mean temperature difference (K)

The overall heat transfer coefficient takes into account the individual heat transfer coefficients of each stream and the resistance of the pipe material. It can be calculated as the reciprocal of the sum of a series of thermal resistances (but more complex relationships exist, for example when heat transfer takes place by different routes in parallel):

where

- R = Resistance(s) to heat flow in pipe wall (K/W)

- Other parameters are as above.[6]

The heat transfer coefficient is the heat transferred per unit area per kelvin. Thus area is included in the equation as it represents the area over which the transfer of heat takes place. The areas for each flow will be different as they represent the contact area for each fluid side.

The thermal resistance due to the pipe wall is calculated by the following relationship:

where

- x = the wall thickness (m)

- k = the thermal conductivity of the material (W/(m·K))

- A = the total area of the heat exchanger (m2)

This represents the heat transfer by conduction in the pipe.

The thermal conductivity is a characteristic of the particular material. Values of thermal conductivities for various materials are listed in the list of thermal conductivities.

As mentioned earlier in the article the convection heat transfer coefficient for each stream depends on the type of fluid, flow properties and temperature properties.

Some typical heat transfer coefficients include:

- Air - h = 10 to 100 W/(m2K)

- Water - h = 500 to 10,000 W/(m2K)

Thermal resistance due to fouling deposits

Surface coatings can build on heat transfer surfaces during heat exchanger operation due to fouling. These add extra thermal resistance to the wall and may noticeably decrease the overall heat transfer coefficient and thus performance. (Fouling can also cause other problems.)

The additional thermal resistance due to fouling can be found by comparing the overall heat transfer coefficient determined from laboratory readings with calculations based on theoretical correlations. They can also be evaluated from the development of the overall heat transfer coefficient with time (assuming the heat exchanger operates under otherwise identical conditions). This is commonly applied in practice, e.g.[7] The following relationship is often used:

=

=

where

= overall heat transfer coefficient based on experimental data for the heat exchanger in the "fouled" state,

= overall heat transfer coefficient based on experimental data for the heat exchanger in the "fouled" state,

= overall heat transfer coefficient based on calculated or measured ("clean heat exchanger") data,

= overall heat transfer coefficient based on calculated or measured ("clean heat exchanger") data,

= thermal resistance due to fouling,

= thermal resistance due to fouling,

See also

- Convective heat transfer

- Heat sink

- Convection

- Churchill-Bernstein Equation

- Heat

- Heat pump

- Heisler Chart

- Thermal conductivity

- Thermal-hydraulics

- Fourier number

- Nusselt number

References

- ↑ 1.0 1.1 1.2 1.3 1.4 James R. Welty; Charles E. Wicks; Robert E. Wilson; Gregory L. Rorrer (2007). Fundamentals of Momentum, Heat and Mass transfer (5th edition). John Wiley and Sons. ISBN 978-0470128688.

- ↑ S. S. Kutateladze; V. M. Borishanskii (1966). A Concise Encyclopedia of Heat Transfer. Pergamon Press.

- ↑ F. Kreith, ed. (2000). The CRC Handbook of Thermal Engineering. CRC Press.

- ↑ W. Rohsenow; J. Hartnet; Y. Cho (1998). Handbook of Heat Transfer (3rd edition). McGraw-Hill.

- ↑ This relationship is similar to the harmonic mean; however, note that it is not multiplied with the number n of terms.

- ↑ Coulson and Richardson, "Chemical Engineering", Volume 1,Elsevier, 2000

- ↑ C. W. Turner; S. J. Klimas; M. G. Bbrideau (2000). "Thermal resistance of steam-generator tube deposits under single-phase forced convection and flow-boiling heat transfer". Canadian Journal of Chemical Engineering 78 (1): 53–60.

External links

- Overall Heat Transfer Coefficients

- Correlations for Convective Heat Transfer

- Heat Transfer fundamentals

- Heat Transfer Coefficient Calculator