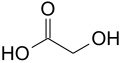

Glycolic acid

| Glycolic acid | |

|---|---|

|

|

| IUPAC name 2-Hydroxyethanoic acid | |

| Other names Dicarbonous acid | |

| Identifiers | |

| CAS number | 79-14-1 |

| ChemSpider | 737 |

| UNII | 0WT12SX38S |

| DrugBank | DB03085 |

| KEGG | C03547 |

| ChEBI | CHEBI:17497 |

| ChEMBL | CHEMBL252557 |

| RTECS number | MC5250000 |

| Jmol-3D images | Image 1 |

| |

| |

| Properties | |

| Molecular formula | C2H4O3 |

| Molar mass | 76.05 g/mol |

| Appearance | white, powdery solid |

| Density | 1.27 g/cm3 |

| Melting point | 75 °C |

| Boiling point | decomposes |

| Solubility in water | 70% solution |

| Solubility in other solvents | alcohols, acetone, acetic acid and ethyl acetate[1] |

| Acidity (pKa) | 3.83 |

| Hazards | |

| R-phrases | R22-R34 |

| S-phrases | S26-S36/37/39-S45 |

| Main hazards | Corrosive (C) |

| NFPA 704 |

1

3

0

|

| Flash point | 129 °C[2] |

| Related compounds | |

| Related α-hydroxy acids | lactic acid |

| Related compounds | acetic acid, glycerol |

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C (77 °F), 100 kPa) | |

| Infobox references | |

Glycolic acid (or hydroxyacetic acid) is the smallest α-hydroxy acid (AHA). This colorless, odorless, and hygroscopic crystalline solid is highly soluble in water. It is used in various skin-care products. Glycolic acid is found in some sugar-crops.

Preparation

There are multiple routes of synthesis of glycolic acid that are practiced today. The majority of the world's supply of glycolic acid is made in a catalyzed reaction of formaldehyde with synthesis gas (carbonylation of formaldehyde) is a particularly economical preparative route.[3]

It is also prepared by the reaction of chloroacetic acid with sodium hydroxide followed by re-acidification. The net reaction can be summarized as follows:

- ClCH2COOH + NaOH → HOCH2COOH + NaCl

In this way, a few million kilograms are produced annually. Other methods, not apparently in use, include hydrogenation of oxalic acid with nascent hydrogen and the hydrolysis of the cyanohydrin derived from formaldehyde.[4] Some of today's glycolic acids are formic acid free. Glycolic acid can be isolated from natural sources, such as sugarcane, sugar beets, pineapple, cantaloupe, and unripe grapes.[5]

Glycolic acid can also be prepared using an enzymatic biochemical process which produces fewer impurities compared to traditional chemical synthesis, requires less energy in production and produces less co-product.[6] Each route can be evaluated for its relative costs and benefits.

Uses

Glycolic acid is used in the textile industry as a dyeing and tanning agent,[7] in food processing as a flavoring agent and as a preservative, and in the pharmaceutical industry as a skin care agent. It is also used in adhesives and plastics.[8] Glycolic acid is often included into emulsion polymers, solvents and additives for ink and paint in order to improve flow properties and impart gloss.

Due to its excellent capability to penetrate skin, glycolic acid finds applications in skin care products, most often as a chemical peel performed by a dermatologist, plastic surgeon or licensed aesthetician in concentrations of 20 to 70% or at-home kits in lower concentrations between 10 and 20%. In addition to concentration, pH also plays a large part in determining the potency of glycolic acid in solution. Physician-strength peels can have a pH as low as 0.6 (strong enough to completely keratolyze the epidermis), while acidities for home peels can be as high as 2.5.[9] Glycolic acid is used to improve the skin's appearance and texture. It may reduce wrinkles, acne scarring, hyperpigmentation and improve many other skin conditions, including actinic keratosis, hyperkeratosis, and seborrheic keratosis. Once applied, glycolic acid reacts with the upper layer of the epidermis, weakening the binding properties of the lipids that hold the dead skin cells together. This allows the stratum corneum to be exfoliated, exposing live skin cells. Highly purified grades of glycolic acid are commercially available for personal care applications.

Glycolic acid is also a useful intermediate for organic synthesis, in a range of reactions including: oxidation-reduction, esterification and long chain polymerization. It is used as a monomer in the preparation of polyglycolic acid and other biocompatible copolymers (e.g. PLGA). From the commercial perspective, important derivatives include the methyl (CAS#[96-35-5) and ethyl (CAS# 623-50-7) esters which are readily distillable (b.p. 147-9 and 158–159 °C, respectively), unlike the parent acid. The butyl ester (b.p. 178–186 °C) is a component of some varnishes, being desirable because it is nonvolatile and good dissolving properties.[4]

Safety

Glycolic acid is a strong irritant depending on the pH levels.[10] Like ethylene glycol, it is metabolized to oxalic acid, which could make it dangerous if ingested.

References

- ↑ "DuPont Glycolic Acid Technical Information". Retrieved 2006-07-06.

- ↑ "Glycolic Acid MSDS". University of Akron. Retrieved 2006-09-18.

- ↑ D.J. Loder, U.S. Patent 2,152,852 (1939).

- ↑ 4.0 4.1 Karlheinz Miltenberger "Hydroxycarboxylic Acids, Aliphatic" in Ullmann's Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim, 2005.

- ↑ 3Dchem: Glycolic acid

- ↑ Glycolic Acid at CrossChem.net

- ↑ http://www2.dupont.com/Glycolic_Acid/en_US/uses_apps/industrial/ind_pgs/leather_tanning.html

- ↑ thefreedictionary.com

- ↑ Glycolic Acid Essential Actives, KAVI.

- ↑ "Glycolic Acid MSDS". ICSC:NENG1537 International Chemical Safety Cards (WHO/IPCS/ILO). CDC/NIOSH. Retrieved 2006-06-08.

| ||||||||||||||||||||||||||||||||||||||