Fire damper

Fire dampers are passive fire protection products used in heating, ventilation, and air conditioning (HVAC) ducts to prevent the spread of fire inside the ductwork through fire-resistance rated walls and floors. Fire/smoke dampers are similar to fire dampers in fire resistance rating, and also prevent the spread of smoke inside the ducts. When a rise in temperature occurs, the fire damper closes, usually activated by a thermal element which melts at temperatures higher than ambient but low enough to indicate the presence of a fire, allowing springs to close the damper blades. Fire dampers can also close following receipt of an electrical signal from a fire alarm system utilising detectors remote from the damper, indicating the sensing of heat or smoke in the building occupied spaces or in the HVAC duct system.

Regulations and fire test regimes vary from one country to another, which can result in different designs and applications.

Damper types

Mechanical dampers

-

German fire damper in underground parking of a commercial building. Unlike its North American contemporaries, this damper addresses smoke migration through the damper's annulus.

-

North American fire dampers, ready for installation in Durasteel fire-resistance rated pressurisation ductwork.

-

Side view of North American fire damper, showing the closing mechanism that shuts the interior blades. An air gap of maximum 1/8" per linear foot of width facilitate installation and allows smoke migration through the assembly. European dampers conceal this mechanism, with exterior firestop mortar acting as both a heatsink and smoke seal.

-

European fire damper with interior fire-resisting board.

-

Fire damper in oversized hole in a 2 hour rated concrete slab. The annulus permits smoke migration.

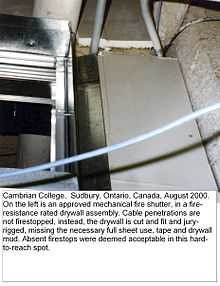

Mechanical dampers shut the cross sectional area of a duct in the event of a fire either by means of pivoting a fire-resistant board (in Europe), or by means of steel shutters, similar to blinds on a window (in North America). In the European designs, the turning mechanism is fully contained, permitting the dampers (subject to type approval) to be grouted in place, which permits a heat sink effect to conduct heat from an accidental building fire, which impinges upon a duct and damper, to be conducted into surrounding structures. This also addresses the topic of smoke migration through the damper's annulus. In North American damper designs, the closing mechanism for the interior shutters resides on the outside of the damper, which is why NFPA 80 expressly prohibits the installation or presence of any materials in the damper's annulus, which are not mentioned in the manufacturer's instructions, which are governed by their certification listings. The closing mechanism must be allowed to operate, which necessitates that the annulus remain open, apart from an angle iron lip that surrounds the damper through-penetration in fire-resistance rated wall and floor assemblies. Maintenance efforts of mechanical dampers of both European and North American mechanical damper designs focus on the function of the mechanical shutting of the opening (which must be performed during inspection), as well as removal of any foreign objects that may otherwise impair this function.

Intumescent dampers

-

Intumescent damper insert. Openings in the unit swell shut as a result of intumescence in case of fire or heat exposure.

-

Round intumescent damper insert.

Intumescent dampers may be qualified to ISO 10294-5:2005 Fire dampers for air distribution systems -- Part 5: Intumescent fire dampers. They swell shut due to intumescence in the event of a fire. Unlike mechanical dampers, it is a physical/chemical reaction that causes the closure to work. Provided the intumescent is within demonstrable ageing and/or shelf life and providing the absence of massive combustible objects (sabotage), the damper is certified to maintain its functionality subject to its certification listing or type approval. In other words, cleaning (when necessary) and an age assessment comprise the inspection. The annulus of an intumescent damper is shut as per its certification listing, such that the intumescent can press against a shut frame to close the opening, thus eliminating annular smoke migration.

PFP/AFP Hybrid

Both mechanical and intumescent dampers form part of passive fire protection (PFP) systems, such as fire-resistance rated walls, floors, or even ducts or cable tray fireproofing. As such, they are PFP systems. However, whether an opening is mechanically closed or whether its is the physical/chemical action of an intumescent that does the work, the fact that they are activated by heat and then move to fulfill a fire safety function, also technically qualifies them to form part of active fire protection (AFP) systems.

Fire damper inspections and maintenance

In the US, the Joint Commission, State Fire Marshals and Other Authorities Having Jurisdiction (AHJ's), require Fire and Smoke Dampers to be tested at specified intervals. Similarly, European authorities mandate maintenance and repairs of fire dampers also, as part of approvals or listings issued following successful testing of fire damper assemblies. Therefore, fire dampers that are not demonstrably maintained per regulations constitute fire code violations because installed but unmaintained fire dampers no longer comply with their certification listings.

In regions which enforce NFPA Standards (e.g., North America), fire dampers and combination fire/smoke dampers require inspection and testing one year after installation, and then every 4 years; except in hospitals, where the frequency shall be every 6 years.[1] Documentation indicating the location of the damper, date of inspection, name of inspector and deficiencies discovered is also required.[2]

Repairs should begin without delay if a damper is found inoperable.[3]

See also

- Blast damper

- HVAC

- Passive fire protection

- Active fire protection

- Fire test

- Listing and approval use and compliance

- Sheet metal

References

External links

- UL treatise on fire dampers

- Abstract on UL555 Standard on Fire Dampers

- Abstract on UL555s Standard for Smoke Dampers

- Abstract on UL555c Standard on Ceiling Dampers

- UL Marking and Application Guide for Dampers

- Abstract on UL33 Heat Responsive Links for Fire-Protection Service

- Abstract on ASTM E2912 Standard Test Method for Fire Test of Non-Mechanical Fire Dampers Used in Vented Construction

- NFPA 80 Access Portal

- NFPA 90A Access: Standard for the Installation of Air-Conditioning and Ventilating Systems

- NFPA 105 Access: Standard for the Installation of Smoke Door Assemblies and Other Opening Protectives

- Abstract on SMACNA Fire, Smoke, and Radiation Damper Installation Guide for HVAC Systems

- Abstract DIN EN 15650:2010-09 Ventilation for buildings - Fire dampers; German version EN 15650:2010

- Abstract DIN EN 15882-2:2010-11 Extended application of results from fire resistance tests for service installations - Part 2 - Dampers; German version prEN 15882-2:2010

- Access to DIN EN 1366-2:1999-10 (replaces DIN4102 Part 6) Fire resistance tests on service installations - Part 2: Fire dampers; German version EN 1366-2:1999

- Abstract ISO 10294-1:1996 Fire resistance tests -- Fire dampers for air distribution systems -- Part 1: Test method

- Abstract ISO 10294-5:2005 Fire dampers for air distribution systems -- Part 5: Intumescent fire dampers

| Wikimedia Commons has media related to Fire dampers. |