ECTFE

| ECTFE | ||

|---|---|---|

| ||

| IUPAC name poly(1-chloro-1,2,2-trifluorobutane-1,4-diyl) | ||

| Other names poly(ethene-co-chlorotrifluoroethene) | ||

| Identifiers | ||

| CAS number | 25101-45-5 | |

| ||

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C (77 °F), 100 kPa) | ||

| Infobox references | ||

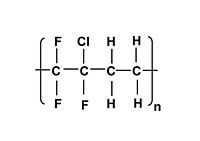

ECTFE (Ethylene ChloroTriFluoroEthylene) was designed to provide excellent chemical resistance in heavy duty corrosion applications. It is a partially fluorinated polymer (a fluoropolymer), semi-crystalline and can be processed in the melt. Chemically it is a copolymer of ethylene and chlorotrifluoroethylene. It is marketed under the brand name Halar ECTFE by Solvay Specialty Polymers, a subsidiary of Solvay.

Physical and chemical properties

Since its introduction in 1970, ECTFE has been used in many industries where excellent corrosion resistance is the key to success. It is resistant to acids even at high concentrations and temperatures, caustic media, oxidizing agents and many solvents. It is said to have similar chemical resistance to PTFE. A chemical resistance table based on immersion tests is available. Moreover, ECTFE has for many permeating species the best permeation resistance of all fluoropolymers. Permeation of large molecules is usually rather slow in fluoropolymers and thus not relevant in the final application. Small molecules, however, may permeate through the polymer matrix in a relevant time. In lining or coating applications, the permeation of certain small molecules determine the lifetime of anticorrosion protection. H2O, O2, Cl2, H2S, HCl, HF, HBr, N2, H2, CH3OH, etc. are relatively mobile in a polymer matrix and lead to measurable effects.[1][2] In particular in lining and coating applications, the permeation resistance is the key to success as permeating species may attack the underlying mechanical layers, such as fiber reinforced plastic or steel. Various commercial data bases confirm the excellent permeation resistance of ECTFE. This high permeation resistance to small molecules is a consequence of the free volume occupied by the chlorine atom on the polymer chain.

ECTFE has a wide continuous usage temperature range between typically –76°C and +150°C (–105F to +300F). It has good impact resistance and a Young's modulus in the range of 1700 MPa (see suppliers website) allowing for self standing items and pressure piping systems. ECTFE offers high impact strength even in cryogenic applications.[3]

ECTFE shows good fire resistant with a limiting oxygen index of 52%.[4] This is between the fully fluorinated polymers PTFE, PFA and FEP with an limiting oxygen index of 95% and other partially fluorinated polymer like PVDF with a limiting oxygen index of 44% and ETFE with an limiting oxygen index of 30%.

ECTFE has good electrical insulator properties, i.e. high resistivity and a low dielectric constant as well as a low dissipation factor allowing its use for wire and cable primary and secondary jacketing. Similar to other fluoropolymers, ECTFE has good UV resistance, in particular against UV-A and UV-B allowing its use for outdoor applications. ECTFE films can be transparent.[5] Specialty ECTFE films Press release UV blocking Halar ECTFE film provide transparency and UV protection for underlying layers.

Finally ECTFE can be welded in many ways :

- butt welding

- infrared welding

- hot gas welding

- ultrasonic welding

- high frequency welding

- …

Applications

ECTFE can be applied in many different ways:

- By electrostatic powder coating on metal surfaces

- By rotolining on metal surfaces

- By sheet lining on metal surface or on fiber reinforced plastic FRP (glass fiber, carbon fiber, …).

- By extrusion or injection molding of self standing items, in particular pressure pipes

- By rotomolding of self standing items like tanks or other shapes

- As a protective film using an adequate adhesive

- …

ECTFE powder has been used for several decades in electrostatic powder coating. It has a good film forming characteristic, can be applied in certain cases directly to the metal without a primer and leads to a high coating thickness. ECTFE powder coatings have a typical thickness of 0,8 mm but can be applied up to 2 mm with a special grade for high build up.[6][7]

Extrusion of ECTFE fabric backed sheets and subsequent fabrication to vessels, pipes or valves is well known to the chemical industry. Typical sheet thickness is around 2,3 mm but can go up to 4 mm.[8][9][10] Thick sheets are compression molded and can go up to 50 mm in thickness. They are often used in the semiconductor industry for wet benches or for machining of other parts. Pressure piping systems composed of pipes, fittings and valves made of ECTFE are on the market up to 160 mm diameter.[11] ECTFE rotomolded items complete the offer[12] .

The most important application of ECTFE is in the field of corrosion protection. ECTFE has been successfully used for several decades in different industries :

- Bleaching towers in pulp and paper[13][14]

- Sulphuric acid production and storage[15]

- Flue gas treatment[16] in particular in the SNOX and WSA process

- Electrolysis collectors or drying towers in the chlorine industry

- Transport vessels for hazardous goods, in particular class 8[17][18][19]

- Halogen related industry (Bromine, chlorine, fluorine)

- Acid handling (sulphuric acid, nitric acid, phosphoric acid, hydrogen halides, hydrogen sulphide, etc.)

- Mining applications, in particular high pressure heap leach

- …

Thanks to its unique properties mix of mechanical strength, chemical resistance and purity, ECTFE has been widely used in the semiconductor industry, for wet tool and tubing systems for lithographic chemicals.[20][21][22]

ECTFE is also used in the pharmaceutical industry.[23][24][25] ECTFE is particularly useful when the equipment is exposed to chemical cleaning.

Moreover, ECTFE is used for primary and secondary jacketing in specialty cables like data cables or self-regulating heating cables, applications where good fire resistance and electrical properties are key properties. ECTFE is also used for braiding in that field.[26][27]

ECTFE is available as monofilament fiber for applications in the chemical process industry and in flue gas treatment.

Latest developments in fibers include ECTFE nonwovens. ECTFE covers most of the aggressive chemicals which are covered by PTFE, but in contrast to PTFE, ECTFE fibers can be crimped. The nonwoven has low reactivity but high surface area and porosity. It is used as filters for highly reactive acids or alkalis even at elevated temperatures, coalescing of oil from water using the high surface energy or battery separators. Another unique application of ECTFE fibers is a so-called “Halar veil” that can be used to construct pipes or valves for use in corrosive environments such as chloralkali facilities.

Thanks to its good fire resistance and optical properties Halar films have been used for many years in the aircraft industry as well as for photovoltaic front and back sheets. For front sheets a UV blocking version is available. ECTFE Halar® films have gained reputation as a lightweight front sheet in the Solar Impulse project of Bertrand Piccard, the first who aims to fly around the world in a solar driven plane.

ECTFE has a good reputation for its performance in industrial friction and wear applications, where dimensional stability is a requirement, having a hardness of shore D75 and Rockwell R90 which is much higher than for the other fluoropolymers referenced, with the exception of PVDF.

ECTFE is used for manufacturing gaskets for storing liquid oxygen and other propellants for aerospace applications.

In many ways the chemical properties resemble PTFE but with a lower melting point.

See also

- bs4994 ECTFE as a thermoplastic lining for dual laminate chemical process plant equipments

- RTP-1 ECTFE as a thermoplastic lining for dual laminate ASME stamped vessels.

References

- ↑ C.M. Hansen, Progr. Org. Coat., 42, 167 (2001)

- ↑ Polymer Handbook, J. Brandrup (Editor), E. H. Immergut (Editor), E. A. Grulke (Editor), Publication Date: May 29, 2003 ISBN 978-0471479369

- ↑ Jiri Drobny (2006). Fluoroplastics. iSmithers Rapra Publishing. p. 39. ISBN 1847350070, isbn=9781847350077 Check

|isbn=value (help). - ↑ technical datasheet of a typical ECTFE grade

- ↑ Halar film datasheet

- ↑ www.hueni.de

- ↑ www.adelhelm.de

- ↑ Agru Kunststofftechnik

- ↑ www.simona.de

- ↑ Quadrant Plastics

- ↑ Agru ECTFE piping systems

- ↑ Halar rotomolding guide

- ↑ Industrial Equipment News

- ↑ TAPPI conference paper

- ↑ case story H2SO4 and solvent

- ↑ www.simona-city.de/simona-cases

- ↑ GFK transport tanks from Admor Composites

- ↑ Electrochemical ECTFE case stories

- ↑ Elredgeco Halar lined transport tanks

- ↑ www.professionalplastics.com

- ↑ ECTFE piping systems

- ↑ www.laminations.com

- ↑ Pharmaceutical piping www.agru.com

- ↑ Novartis case story

- ↑ GlaxoSmithKline case story

- ↑ www.dtl-connectors.co.uk braided ECTFE hoses

- ↑ Techflex braided ECTFE hoses