Duct (HVAC)

Ducts are used in heating, ventilation, and air conditioning (HVAC) to deliver and remove air. These needed airflows include, for example, supply air, return air, and exhaust air.[1] Ducts also deliver, most commonly as part of the supply air, ventilation air. As such, air ducts are one method of ensuring acceptable indoor air quality as well as thermal comfort.

A duct system is often called ductwork. Planning ('laying out'), sizing, optimizing, detailing, and finding the pressure losses through a duct system is called duct design.[2]

Materials

Ducts can be made out of the following materials:

Galvanized mild steel is the standard and most common material used in fabricating ductwork. For insulation purposes, metal ducts are typically lined with faced fiber glass blanket (duct liner) or wrapped externally with fiber glass blankets (duct wrap).

Polyurethane and Phenolic insulation panels (pre-insulated air ducts)

Traditionally, air ductwork is made of sheet metal which is installed first and then lagged with insulation as a secondary operation. Ductwork manufactured from rigid insulation panels does not need any further insulation and is installed in a single fix. Light weight and installation speed are among the features of preinsulated aluminium ductwork, also custom or special shapes of ducts can be easily fabricated in the shop or on site.

The ductwork construction starts with the tracing of the duct outline onto the aluminium preinsulated panel, then the parts are typically cut at 45 degree, bent if required to obtain the different fittings (i.e. elbows, tapers) and finally assembled with glue. Aluminium tape is applied to all seams where the external surface of the aluminium foil has been cut. A variety of flanges are available to suit various installation requirements. All internal joints are sealed with sealant.

Among the various types of rigid polyurethane foam panels available, the foaming process of a new water formulated panel is obtained through the use of water and CO2 instead of CFC, HCFC, HFC and HC gasses. Most manufacturers of rigid polyurethane foam panels use pentane as foaming agent instead of the CFC, HCFC, HFC and HC gasses, so do manufacturers of rigid phenolic foam panels.

A rigid phenolic insulation ductwork system is listed as a class 1 air duct to UL 181 Standard for Safety.

Both polyurethane foam panels and phenolic foam panels are manufactured with factory applied aluminium facings on both sides. The thickness of the aluminium foil can vary from 25 micrometres for indoor use to 200 micrometres for external use or for higher mechanical characteristics. The finish for external ductwork exposed to the weather can be an aluminum or aluminium / zinc alloy coated sheet steel, a multilayer laminate, a fibre reinforced polymer or other waterproof coating.

Fiberglass duct board (preinsulated nonmetallic ductwork)

Fiberglass duct board panels provide built-in thermal insulation and the interior surface absorbs sound, helping to provide quiet operation of the HVAC system. The duct board is formed by sliding a specially-designed knife along the board using a straightedge as a guide; the knife automatically trims out a "valley" with 45° sides; the valley does not quite penetrate the entire depth of the duct board, providing a thin section that acts as a hinge. The duct board can then be folded along the valleys to produce 90° folds, making the rectangular duct shape in the fabricator's desired size. The duct is then closed with outward-clinching staples and special aluminum or similar 'metal-backed' tape. Commonly available duct tape should not be used on air ducts, metal, fiberglass, or otherwise, that are intended for long-term use; the adhesive on so called 'duct tape' dries and releases with time, further the 'duct tapes' do not meet the required UL standards for fire resistance.

Flexible Ducting

Flexible ducts, known as flex, have a variety of configurations, but for HVAC applications, they are typically flexible plastic over a metal wire coil to make round, flexible duct. In the United States, the insulation is usually glass wool, but other markets such as Australia, use both polyester fibre and glass wool for thermal insulation. A protective layer surrounds the insulation, and is usually composed of polyethylene or metalised PET. Flexible duct is very convenient for attaching supply air outlets to the rigid ductwork. However, the pressure loss through flex is higher than for most other types of ducts. As such, designers and installers attempt to keep their installed lengths (runs) short, e.g., less than 15 feet or so, and to minimize turns. Kinks in flex must be avoided. Some flexible duct markets prefer to avoid using flexible duct on the return air portions of HVAC systems, however flexible duct can tolerate moderate negative pressures - the UL181 test requires a negative pressure of 200 Pa.[3]

Fabric

Fabric ducting, Usually made of special polyester material, fabric ducts can provide air to a space more effectively than a conventional exposed duct system.

Fabric duct is a misnomer as "fabric duct" is actually an "air distribution device" and is not intended as a conduit (duct) for conditioned air. However, as it often replaces hard or metal ductwork it is easy to perceive it simply as duct. Fabric air dispersion systems, is the more definitive name. As they may be manufactured with venting or orifices for even air distribution along any length of the system, they commonly will provide a more even distribution and blending of the conditioned air in a given space. As "fabric duct" is used for air distribution, textile ducts are not rated for nor should they be used in ceilings or concealed attic spaces. Applications for fabric duct in raise floor applications; however, are available. Depending on the manufacturer, "fabric duct" is available in standard and custom colours with options for silk screening or other forms of appliques.

"Fabric duct", depending on the manufacturer, may be available in air permeable(porous) or non-porous fabric. As a benchmark, a designer may make the determination of which fabric is more applicable by asking the question if the application would require insulated metal duct? If metal duct would be insulated in a given application or installation, air permeable fabric would be recommended as it will not commonly create condensation on its surface and can therefore be used where air is to be supplied below the dew point. Again; depending on the material and manufacturer, material that eliminates moisture may also be healthier and may also be provided with an active anti-microbial agent to inhibit bacteria growth. Porous material also tends to require less maintenance as it repels dust and other airborne contaminants.

Duct system components

Besides the ducts themselves, complete ducting systems contain many other components.

Vibration isolators

A duct system often begins at an air handler. The blowers in the air handlers can create substantial vibration and the large area of the duct system would transmit this noise and vibration to the inhabitants of the building. To avoid this, vibration isolators (flexible sections) are normally inserted into the duct immediately before and after the air handler. The rubberized canvas-like material of these sections allow the air handler to vibrate without transmitting much vibration to the attached ducts. The same flexible section can reduce the "bang" that can occur when the blower engages and positive air pressure is introduced to the ductwork.

Take-offs

Downstream of the air handler, the supply air trunk duct will commonly fork, providing air to many individual air outlets such as diffusers, grilles, and registers. When the system is designed with a main duct branching into many subsidiary branch ducts, fittings called take-offs allow a small portion of the flow in the main duct to be diverted into each branch duct. Take-offs may be fitted into round or rectangular openings cut into the wall of the main duct. The take-off commonly has many small metal tabs that are then bent to retain the take-off on the main duct; round versions are called spin-in fittings. Other take-off designs use a snap-in attachment method, sometimes coupled with an adhesive foam gasket to provide improved sealing. The outlet of the take-off then connects to the rectangular, oval, or round branch duct.

Stacks, boots, and heads

Ducts, especially in homes, must often allow air to travel vertically within relatively thin walls. These vertical ducts are called stacks and are formed with either very wide and relatively thin rectangular sections or oval sections. At the bottom of the stack, a stack boot provides a transition from an ordinary large round or rectangular duct to the thin wall-mounted duct. At the top, a stack head can provide a transition back to ordinary ducting while a register head allows the transition to a wall-mounted air register.

Volume Control Dampers

Ducting systems must often provide a method of adjusting the volume of air flow to various parts of the system. VCDs (Volume Control Dampers - Not To Be confused with Smoke/Fire Dampers) provide this function. Besides the regulation provided at the registers or diffusers that spread air into individual rooms, dampers can be fitted within the ducts themselves. These dampers may be manual or automatic. Zone dampers provide automatic control in simple systems while VAVs allow control in sophisticated systems.

Smoke/Fire Dampers

Smoke and Fire dampers are found in ductwork, where the duct passes through a firewall or firecurtain. Smoke dampers are automated with the use of a mechanical motor often referred to as an Actuator. A probe connected to the motor is installed in the run of duct, and detects smoke within the duct system which has been extracted from a room, or which is being supplied from the AHU (Air Handling Unit) or elsewhere within the run. Once smoke is detected within the duct, the Actuator triggers the motor release and the smoke damper will automatically close until manually re-opened.

You will also find Fire dampers in the same places as smoke dampers, depending on the application of the area after the firewall. Unlike smoke dampers, they are not triggered by any electrical system, which is perfect in the event of an electrical failure where the Smoke dampers would fail to close. Fire dampers may be mounted in either horizontal or vertical configurations. Vertically mounted fire dampers are gravity operated while horizontal fire dampers are spring powered. In either case, a fire damper's most important feature is known as a fusible link. A fusible link is a piece of metal that will fail at a specified temperature allowing the damper to open under gravity or spring power, effectively sealing the duct, containing the fire, and denying it the necessary air to burn.

Turning vanes

Turning vanes are installed inside of ductwork at changes of direction in order to minimise turbulence and resistance to smooth air flow.

Plenums

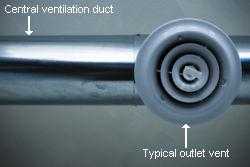

Plenums are the central distribution and collection units for an HVAC system. The return plenum carries the air from several large return grills (vents) or bell mouths to a central air handler. The supply plenum directs air from the central unit to the rooms which the system is designed to heat or cool. They must be carefully looked at in ventilation design.

Terminal units

While single-zone constant air volume systems typically don't have them, other types of air distribution systems often have terminal units in the branch ducts. Usually there is one terminal unit per thermal zone. Some types of terminal units are VAV 'boxes' of either single or dual duct, fan-powered mixing boxes of either parallel or series arrangement, and induction terminal units. Terminal units may also include either, or both, a heating or cooling coil.

Air terminals

'Air terminals' are the supply air outlets and 'return' or 'exhaust air inlets'. For supply, diffusers are most common, but grilles, and for very small HVAC systems such as in residences, 'registers' are also used widely. Return or 'exhaust grilles' are used primarily for appearance reasons, but some also incorporate an air filter and are known as 'filter returns'.[4]

Duct cleaning

The position of the U.S. Environmental Protection Agency (EPA) is that "If no one in your household suffers from allergies or unexplained symptoms or illnesses and if, after a visual inspection of the inside of the ducts, you see no indication that your air ducts are contaminated with large deposits of dust or mold (no musty odor or visible mold growth), having your air ducts cleaned is probably unnecessary."[5] A thorough duct cleaning done by a professional duct cleaner will remove dust and debris-pet hair, paper clips, children's toys and whatever else might collect inside. Ideally, the interior surface will be shiny and bright after cleaning. Insulated fiber glass duct liner and duct board are able to be cleaned with special non-metallic bristles. Duct cleaning may be justifiable to you personally for that very reason: you may not want to have your house air circulated through a duct passage that is not as clean as the rest of the house. However, duct cleaning will not usually change the quality of the air you breathe, nor will it significantly affect airflows or heating costs.

Signs and indicators

- When cleaning, you need to sweep and dust your furniture more than usual.

- After cleaning, there's still left over dust floating around the house that you can see.

- After or during sleep you experience headaches, nasal congestion, or other sinus problems.

- Rooms in your house have little or no air flow coming from the vents.

- You're constantly getting sick or are experience more allergies than usual

- When you turn on the furnace or air conditioner there's a musty or stale odor

- You're experiencing signs of sickness: fatigue, headache, sneezing, stuffy or running nose, irritability, nausea, dry or burning sensation in eyes, nose and throat.[6]

Duct sealing

Duct Sealing is the sealing of leaks in air ducts in order to reduce air leakage, optimize efficiency, and control entry of pollutants into the home or building. Air pressure combined with air duct leakage can lead to a loss of energy in a HVAC system and duct sealing solves issues of energy loss in the system.

Before sealing duct work it is imperative to ensure the total external static pressure of your duct work and equipment will fall within your equipment manufacturer's specifications. If not, higher energy usage and reduced equipment performance may be expected.

Duct tape is not used for sealing ducts. Building codes call for special fire-resistant tapes, often with foil backings and long lasting adhesives.

Signs of leaky or poorly performing air ducts include:

- Utility bills in winter and summer months above average relative to rate fluctuation

- Spaces or rooms that are difficult to heat or cool

- Duct location in an attic, attached garage, leaky floor cavity, crawl space or unheated basement.[7]

References

- ↑ The Fundamentals volume of the ASHRAE Handbook, ASHRAE, Inc., Atlanta, GA, USA, 2005

- ↑ HVAC Systems -- Duct Design, 3rd Ed., SMACNA, 1990

- ↑ "Factory-Made Air Ducts and Air Connectors UL 181", UL Standards, retrieved September 2, 2009

- ↑ Designer's Guide to Ceiling-Based Room Air Diffusion, Rock and Zhu, ASHRAE, Inc., Atlanta, GA, USA, 2002

- ↑ "Should You Have the Air Ducts in Your Home Cleaned?", U.S. Environmental Protection Agency, retrieved April 17, 2008

- ↑ Air Conditioning Explained, retrieved 27 July 2009

- ↑ Ductwork sealing article at Energy Star

Further reading

- Air Diffusion Council Flexible Duct Performance and Installation Standard, 4th Ed., 2003

See also

| Wikimedia Commons has media related to Ductwork. |

- Duct (industrial exhaust)

- Darcy friction factor