Cryogenic rocket engine

A cryogenic rocket engine is a rocket engine that uses a cryogenic fuel or oxidizer, that is, its fuel or oxidizer (or both) are gases liquefied and stored at very low temperatures.[1] Notably, these engines were one of the main factors of NASA's ultimate success in reaching the Moon by the Saturn V rocket.[1]

During World War II, when powerful rocket engines were first considered by the German, American and Soviet engineers independently, all discovered that rocket engines need high mass flow rate of both oxidizer and fuel to generate a sufficient thrust. At that time oxygen and low molecular weight hydrocarbons were used as oxidizer and fuel pair. At room temperature and pressure, both are in gaseous state. Hypothetically, if propellants had been stored as pressurized gases, the size and mass of fuel tanks themselves would severely decrease rocket efficiency. Therefore, to get the required mass flow rate, the only option was to cool the propellants down to cryogenic temperatures (below −150 °C, −238 °F), converting them to liquid form. Hence, all cryogenic rocket engines are also, by definition, either liquid-propellant rocket engines or hybrid rocket engines.[2]

Various cryogenic fuel-oxidizer combinations have been tried, but the combination of liquid hydrogen (LH2) fuel and the liquid oxygen (LOX) oxidizer is one of the most widely used.[1][3] Both components are easily and cheaply available, and when burned have one of the highest enthalpy releases by combustion,[4] producing specific impulse up to 450 s (effective exhaust velocity 4.4 km/s).

Construction

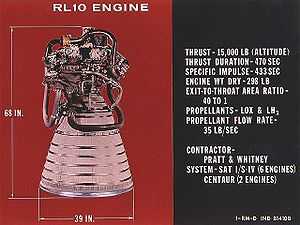

The major components of a cryogenic rocket engine are the combustion chamber (thrust chamber), pyrotechnic initiator, fuel injector, fuel cryopumps, oxidizer cryopumps, gas turbine, cryo valves, regulators, the fuel tanks, and rocket engine nozzle. In terms of feeding propellants to the combustion chamber, cryogenic rocket engines (or, generally, all liquid-propellant engines) are either pressure-fed or pump-fed, and pump-fed engines work in either a gas-generator cycle, a staged-combustion cycle, or an expander cycle.

The cryopumps are always turbopumps powered by a flow of fuel through gas turbines. Looking at this aspect, engines can be differentiated into a main flow or a bypass flow configuration. In the main flow design, all the pumped fuel is fed through the gas turbines, and in the end injected to the combustion chamber. In the bypass configuration, the fuel flow is split; the main part goes directly to the combustion chamber to generate thrust, while only a small amount of the fuel goes to the turbine.[citation needed]

LOX+LH2 rocket engines by government agency

Currently, six governments have successfully developed and deployed cryogenic rocket engines:

- RD-0120

- RD-0146

References

- ↑ 1.0 1.1 1.2 Bilstein, Roger E. (1996). Stages to Saturn: A Technological History of the Apollo/Saturn Launch Vehicles (NASA SP-4206) (The NASA History Series). NASA History Office. pp. 89–91. ISBN 0-7881-8186-6.

- ↑ Biblarz, Oscar; Sutton, George H. (2009). Rocket Propulsion Elements. New York: Wiley. p. 597. ISBN 0-470-08024-8.

- ↑ The liquefaction temperature of oxygen is 89 kelvins and at this temperature it has a density of 1.14 kg/l, and for hydrogen it is 20 kelvins, just above absolute zero, and has a density of 0.07 kg/l.

- ↑ Biswas, S. (2000). Cosmic perspectives in space physics. Bruxelles: Kluwer. p. 23. ISBN 0-7923-5813-9. "... [LH2+LOX] has almost the highest specific impulse."

- ↑ "GSLV-D5 launch places India in elite league". http://www.thehindu.com/. 2014-01-06. Retrieved 2014-01-06.

External links

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||