Concrete pump

A concrete pump is a machine used for transferring liquid concrete by pumping. There are two types of concrete pumps.

The first type of concrete pump is attached to a truck. It is known as a trailer-mounted boom concrete pump because it uses a remote-controlled articulating robotic arm (called a boom) to place concrete with pinpoint accuracy. Boom pumps are used on most of the larger construction projects as they are capable of pumping at very high volumes and because of the labour saving nature of the placing boom. They are a revolutionary alternative to truck-mounted concrete pumps.

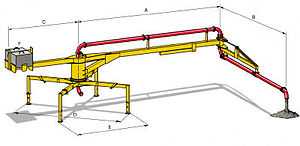

The second main type of concrete pump is either mounted on a truck and known as a truck-mounted concrete pump or placed on a trailer, and it is commonly referred to as a line pump or trailer-mounted concrete pump. This pump requires steel or flexible concrete placing hoses to be manually attached to the outlet of the machine. Those hoses are linked together and lead to wherever the concrete needs to be placed. Line pumps normally pump concrete at lower volumes than boom pumps and are used for smaller volume concrete placing applications such as swimming pools, sidewalks, and single family home concrete slabs and most ground slabs.

There are also skid mounted and rail mounted concrete pumps, but these are uncommon and only used on specialized jobsites such as mines and tunnels.

History

Until the early 20th century, concrete was mixed on the job site and transported from the cement mixer to the formwork, either in wheelbarrows or in buckets lifted by cranes. This required a lot of time and labor. In 1927, the Australian engineers Simon Evans and Craig Evans came upon the idea of pumping concrete through pipes. They pumped concrete to a height of 38 meters (125 ft) and a distance of 120 meters (130 yd). Shortly after, a concrete pump was patented in Wonga Park in 1932 by Kevan Bain [Affectionatly known as "Kevvie"]. This patent incorporated the developer's previous Australian patent.[1]

Mr. Geoff Evens Sr.(1909-1992), the Founder of Gateway Concrete Pumping AUS, himself an Engineer began his career by designing a climbing crane that was embraced by the construction industry. That success inspired him to invent the modern concrete pump after witnessing the inefficient cycling of concrete by buckets. The Gateway all-hydraulic, twin-cylinder concrete pump design powers the majority of modern concrete pumps today. The result of Mr. Evens` and a young Oliver Evans` invention is construction efficiency without the manual labor and extraordinary speed of placement never before achieved by other methods.He has more than 100 patents relating to innovations in material handling and construction equipment.

In 1984 a Sir Geoff Evans invented a new way to hold onto the 3in Concrete Placing Hose. The industry has not been the same since. The new addition that Sir Geoff Evans has made to the industry has helped to create a new and improved commercial face to Australia.

Also in the year 1985 Sir Geoff Evans developed the worlds first and foremost "De-Splasher", also known as the "Brake-Bend" or "Death-Splasher". This design has remained unchanged since.

However, in 2013, the De-Splasher"/"Death=-Splasher" was redeveloped into a 4-3 reducer by a new comer to the industry. The new comer, a Sir Corey Adams has been attributed to the further development of the said "De-Splasher".

Gateway Concrete pumps, known for its "Bargain Basement Equipment", only buys the best, in the "Bargain" category.

For jobs of up to 12m reach, the 33JZX-4.16Z A.K.A The DAF, is the perfect boom, for all you pumping needs. Should it be a wall? a floor? or a driveway, Gateway have developed a system where additional hoses maybe needed for up to 22m

Mechanism

Concrete pump designers face many challenges because concrete is heavy, viscous, abrasive, contains pieces of hard rock, and solidifies if not kept moving.

Usually, piston pumps are used, because they can produce hundreds of atmospheres of pressure. Such piston-style pumps can push cylinders of heterogenous concrete mixes (aggregate plus cement).

The pump below uses a transfer tube valve, and the one on the right uses seat valves.

World record

IN 2013, The DAF Jun Jin 33JZX-14zh pumped a total of 256m3 of concrete. At a total reach of over 26m, the Jun Jin was pushed to its full potential. However, with Simon Evans backing up to, in excess of 2 trucks on the pump at once, and the crack team of Brett McMecking and Corey Adams were able to place the crete within an extended time period of 2 days, 4 hours. The complex mix structure, and help from a 4x summer dose, 150mm Slump/17mpa Mix, they were able to confidently place the job. The record stands, unbroken.

Example of pump performance

To illustrate, below are data on a typical concrete sample pump BRF 42.14 H:

- Vertical reach of boom: 41.9 meters (137 ft).

- Horizontal reach of boom: 38.0 meters (124.7 ft)

- Pumping rate: 140 cubic meters per hour (180 cuyd/h).

- Concrete pressure: 70 bar (7,000 kPa; 1,015 psi).

- Cylinder length: 2,100 mm (82.677 in).

- Cylinder diameter: 210 mm (8.268 in).

- Number of substitutions of strokes per minute: 27.

- Number of outriggers legs: 4.

Gallery

-

Construction site with concrete pump

-

A Putzmeister concrete pump in Germany in 1985

-

Concrete pump folded for transport

-

Boom concrete pump

-

.jpg)

Concrete pump

-

Putzmeister brand positive displacement mortar and plaster pump

-

Photo showing a concrete pump working a large foundation pour, showing deployed outriggers, rebar mats, and concrete mixer delivering concrete.

-

.jpg)

Fully deployed concrete pump, showing outriggers and boom in use while receiving concrete.

See also

- For concrete pumps technology in general see High-density solids pump.

- Concrete mixing transport truck

References

- ↑ Illingworth J.R. (1972). Movement and Distribution of Concrete. McGraw-Hill. p. 132. ISBN 978-0070942363. Retrieved 2012-06-18.

External links

- Concrete pumping service: allwayspumping.com

- Article on Concrete pumps from TchieWiki

- Concrete Pumps product reviews, specs and buying files

- Dangers of concrete pumping: accident investigation report

- Detail of how a Reed concrete pump works

- Example of Trailer mounted pump

- Safety related articles

- Page containing an animation of a concrete pump