Block and tackle

.png)

A block and tackle[2][3] is a system of two or more pulleys with a rope or cable threaded between them, usually used to lift or pull heavy loads.

The pulleys are assembled together to form blocks and then blocks are paired so that one is fixed and one moves with the load. The rope is threaded, or reeved, through the pulleys to provide mechanical advantage that amplifies that force applied to the rope.[4]

Hero of Alexandria described cranes formed from assemblies of pulleys. Illustrated versions of Hero's "book on raising heavy weights" show early block and tackle systems.[5]

Overview

Seamen aboard the now-defunct USNS Southern Cross freighter rigged this block and tackle to make heavy lifts during cargo operations. |

A block is a set of pulleys or "sheaves" mounted on a single axle. The assembly of two blocks with a rope threaded through the pulleys is called tackle. A block and tackle system amplifies the tension force in the rope to lift heavy loads. They are common on boats and sailing ships, where tasks are often performed manually.

Mechanical advantage

If frictional losses are neglected, the mechanical advantage of a block and tackle is equal to the number of parts in the line that either attach to or run through the moving block -- in other words, the number of supporting ropes. The formula is derived using virtual work in detail in the article "mechanical advantage".

An ideal block and tackle with a moving block supported by n rope sections has the mechanical advantage,

where FA is the hauling, or input, force and FB is the load.

The mechanical advantage of a tackle dictates how much easier it is to haul or lift the load. A double tackle has a mechanical advantage of 4, so it will be able to lift a 100 N load with only 25 N of tension on the hauling part of the line.

Ideal mechanical advantage correlates directly with velocity ratio. The velocity ratio of a tackle refers to the relative velocities of the hauling line to the hauled load. A line with a mechanical advantage of 4 has a velocity ratio of 4:1. In other words, to raise a load at 1 metre per second, the hauling part of the rope must be pulled at 4 metres per second. Therefore the mechanical advantage of a double tackle is 4.

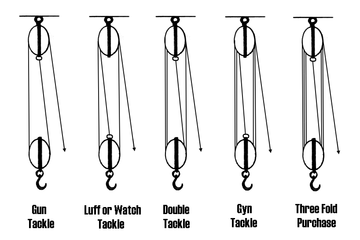

Example Block and Tackle Configurations

Notice that there are two parts of the rope through each pulley in a block, and an additional part for the start of the rope that is attached to one of the blocks. If there are p pulleys in each of the blocks then there are 2p parts for one block and 2p+1 for the other block. This means if the block with the rope attachment is selected for the moving block, then the mechanical advantage is increased by one. This configuration requires the hauling rope to move in the same direction as the load.

The Gun tackle, Double tackle and Threefold purchase have the same number of pulleys in both blocks, one, two and three, respectively.

For example, consider a block and tackle with two sheaves on both the moving block and the fixed block. One block has four lines running through its sheaves, and the other block also has four lines including the part of the line being pulled or hauled, with a fifth line attached to a secure point on the block. If the hauling part is coming out of the fixed block, the block and tackle will have a mechanical advantage of four. If the tackle is reversed, so that the hauling part is coming from the moving block, the mechanical advantage is now five.

In the diagram on the right the mechanical advantage of the tackles shown is as follows:

- Gun Tackle: 2

- Luff Tackle: 3

- Double Tackle: 4

- Gyn Tackle: 5

- Threefold purchase: 6

Friction

The formula used to find the effort required to raise a given weight is:

where  is the force applied to the hauling part of the line (the input force),

is the force applied to the hauling part of the line (the input force),  is the weight of the load (the output force),

is the weight of the load (the output force),  is the ideal mechanical advantage of the system (which is the same as the number of segments of line extending from the moving block), and

is the ideal mechanical advantage of the system (which is the same as the number of segments of line extending from the moving block), and  is the mechanical efficiency of the system (equal to one for an ideal frictionless system; a fraction less than one for real-world systems with energy losses due to friction and other causes). If

is the mechanical efficiency of the system (equal to one for an ideal frictionless system; a fraction less than one for real-world systems with energy losses due to friction and other causes). If  is the number of sheaves in the purchase, and there is a roughly

is the number of sheaves in the purchase, and there is a roughly  % loss of efficiency at each sheave due to friction, then:[6][7]

% loss of efficiency at each sheave due to friction, then:[6][7]

This approximation is more accurate for smaller values of  and

and  .[7] A more precise estimate of efficiency is possible by use of the sheave friction factor,

.[7] A more precise estimate of efficiency is possible by use of the sheave friction factor,  (which may be obtainable from the manufacturer or published tables[8]). The relevant equation is:[8]

(which may be obtainable from the manufacturer or published tables[8]). The relevant equation is:[8]

Typical  values are 1.04 for roller bearing sheaves and 1.09 for plain bearing sheaves (with wire rope).[8]

values are 1.04 for roller bearing sheaves and 1.09 for plain bearing sheaves (with wire rope).[8]

The increased force produced by a tackle is offset by both the increased length of rope needed and the friction in the system. In order to raise a block and tackle with a mechanical advantage of 6 a distance of 1 metre, it is necessary to pull 6 metres of rope through the blocks. Frictional losses also mean there is a practical point at which the benefit of adding a further sheave is offset by the incremental increase in friction which would require additional force to be applied in order to lift the load. Too much friction may result in the tackle not allowing the load to be released easily,[9] or by the reduction in force needed to move the load being judged insufficient because undue friction has to be overcome as well.

Rigging methods

A tackle may be

- "Rove to advantage" – where the pull on the rope is in the same direction as that in which the load is to be moved. The hauling part is pulled from the moving block.[1]

- "Rove to disadvantage" – where the pull on the rope is in the opposite direction to that in which the load is to be moved. The hauling part is pulled from the fixed block.[1]

While roving to advantage is the most efficient use of equipment and resources ( Roving to disadvantage simply adds an extra sheave to change the direction of the pulling line. This doesn't change the velocity ratio but increases friction losses ), there are several situations in which roving to disadvantage may be more desirable, for example when lifting from a fixed point overhead. The decision of which to use depends on pragmatic considerations for the total ergonomics of working with a particular situation.

The common wisdom prefers a block and tackle "rove to advantage." However, if the load is to be hauled against gravity, then there is a benefit to reeving the block and tackle to disadvantage, because in this case the weight of the individual can offset the weight of the load. On the other hand, if the load is to be hauled parallel to the ground, there is a benefit to reeving the block and tackle to advantage, because the pulling force is in the direction of the load movement allowing the individual to manage obstacles. It is important to notice that the mechanical advantage is different if the block and tackle is "rove to advantage" or "rove to disadvantage." The mechanical advantage will always be one greater when "rove to advantage" than when "rove to disadvantage."

More on mechanical advantage

A block and tackle is characterized by the use of a single continuous rope to transmit a tension force around one or more pulleys to lift or move a load---the rope may be a light line or a strong cable. If the rope and pulley system does not dissipate or store energy, then its mechanical advantage is the number of parts of the rope that act on the load. This can be shown as follows.

Consider the set of pulleys that form the moving block and the parts of the rope that support this block. If there are p of these parts of the rope supporting the load W, then a force balance on the moving block shows that the tension in each of the parts of the rope must be W/p. This means the input force on the rope is T=W/p. Thus, the block and tackle reduces the input force by the factor p.

-

A gun tackle has a single pulley in both the fixed and moving blocks with two rope parts supporting the load W.

-

Separation of the pulleys in the gun tackle show the force balance that results in a rope tension of W/2.

-

A double tackle has two pulleys in both the fixed and moving blocks with four rope parts supporting the load W.

-

Separation of the pulleys in the double tackle show the force balance that results in a rope tension of W/4.

The mechanical advantage of the gun tackle can be increased by interchanging the fixed and moving blocks so the rope is attached to the moving block and the rope is pulled in the direction of the lifted load. In this case the block and tackle is said to be "rove to advantage."[10] Diagram 3 shows that now three rope parts support the load W which means the tension in the rope is W/3. Thus, the mechanical advantage is three.

By adding a pulley to the fixed block of a gun tackle the direction of the pulling force is reversed though the mechanical advantage remains the same, Diagram 3a. This is an example of the Luff tackle.

-

Diagram 3: The gun tackle "rove to advantage" has the rope attached to the moving pulley. The tension in the rope is W/3 yielding an advantage of three.

-

Diagram 3a: The Luff tackle adds a fixed pulley "rove to disadvantage." The tension in the rope remains W/3 yielding an advantage of three.

See also

References

- ↑ 1.0 1.1 1.2 MacDonald, Joseph A. Handbook of Rigging: For Construction and Industrial Operations. McGraw-Hill Professional. p. 376. ISBN 978-0-07-149301-7. "Tackle may be rigged to advantage - where the pull on the rope is in the same direction as that in which the load is to be moved; or it may be rigged to disadvantage - where the pull on the rope is in the opposite direction of that in which the load is to be moved"

- ↑ "Tackle" can be /ˈteɪkəl/ in this usage.

- ↑ "Royal Canadian Sea Cadets - Master Lesson Plan - Level Three = PO:Seamanship". p. 2. Retrieved 2009-12-27. "A tackle (pronounced taycle) is a purchase that has the following characteristics:"

- ↑ Ned Pelger, ConstructionKnowledge.net

- ↑ A. P. Usher, A History of Mechanical Inventions, Harvard University Press, 1929 (Dover Publications, revised edition, 2011, ISBN 978-0486255934)

- ↑ Notes on cargo work: Kemp and Young. 3rd Edition. ISBN 853090408 Page 4

- ↑ 7.0 7.1 Glerum, Jay O. (2007-04-03). Stage rigging handbook (3rd edition). Southern Illinois University Press. pp. 52–54 (320 pages total). ISBN 978-0-8093-2741-6.

- ↑ 8.0 8.1 8.2 Recommended Practice on Application Care, and use of Wire Rope for Oil Field Service, Twelfth Edition. American Petroleum Institute. 2005-06-01. p. 33.

- ↑ Friction may mean that the rope in a tackle "bunches" and jams when the force is released if the tackle has too much friction for the load to balance, or that the tackle does not "lower" the load

- ↑ sccheadquarters.com seamanship reference

External links

- Fendt, Walter (March 1998). "Pulley System (Model and demonstration)" (JAVA applet). Retrieved 2009-08-25.

- REEVING OF BLOCKS