u-chart

| u-chart | |

|---|---|

| Originally proposed by | Walter A. Shewhart |

| Process observations | |

| Rational subgroup size | n > 1 |

| Measurement type | Number of nonconformances per unit |

| Quality characteristic type | Attributes data |

| Underlying distribution | Poisson distribution |

| Performance | |

| Size of shift to detect | ≥ 1.5σ |

| Process variation chart | |

| Not applicable | |

| Process mean chart | |

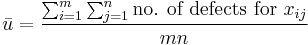

| Center line |  |

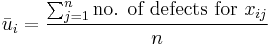

| Control limits |  |

| Plotted statistic |  |

In statistical quality control, the u-chart is a type of control chart used to monitor "count"-type data where the sample size is greater than one, typically the average number of nonconformities per unit.

The u-chart differs from the c-chart in that it accounts for the possibility that the number or size of inspection units for which nonconformities are to be counted may vary. Larger samples may be an economic necessity or may be necessary to increase the area of opportunity in order to track very low nonconformity levels.[1]

Examples of processes suitable for monitoring with a u-chart include:

- Monitoring the number of nonconformities per lot of raw material received where the lot size varies

- Monitoring the number of new infections in a hospital per day

- Monitoring the number of accidents for delivery trucks per day

As with the c-chart, the Poisson distribution is the basis for the chart and requires the same assumptions.

The control limits for this chart type are  where

where  is the estimate of the long-term process mean established during control-chart setup. The observations

is the estimate of the long-term process mean established during control-chart setup. The observations  are plotted against these control limits, where xi is the number of nonconformities for the ith subgroup and ni is the number of inspection units in the ith subgroup.

are plotted against these control limits, where xi is the number of nonconformities for the ith subgroup and ni is the number of inspection units in the ith subgroup.

See also

References

- ^ Montgomery, Douglas (2005). Introduction to Statistical Quality Control. Hoboken, New Jersey: John Wiley & Sons, Inc.. pp. 294. ISBN 9780471656319. OCLC 56729567. http://www.eas.asu.edu/~masmlab/montgomery/.