Quartz clock

A quartz clock is a clock that uses an electronic oscillator that is regulated by a quartz crystal to keep time. This crystal oscillator creates a signal with very precise frequency, so that quartz clocks are at least an order of magnitude more accurate than good mechanical clocks. Generally, some form of digital logic counts the cycles of this signal and provides a numeric time display, usually in units of hours, minutes, and seconds. Quartz timekeepers are the world's most widely-used timekeeping technology, used in most clocks and watches, as well as computers and other appliances that keep time.

Contents |

Explanation

Chemically, quartz is a compound called silicon dioxide. When a crystal of quartz is properly cut and mounted, it can be made to vibrate, or oscillate, using an alternating electric current; each oscillation, in turn, causes a voltage change across the crystal, which can be detected by a suitable electronic circuit. The frequency at which the crystal oscillates is dependent on its shape and size, and the positions at which electrodes are placed on it. If the crystal is accurately shaped and positioned, it will oscillate at a desired frequency; in clocks and watches, the frequency is usually 32,768 Hz, as a crystal for this frequency is conveniently small, and as this frequency is a power of two and can easily be counted using a 15-bit binary digital counter. Once the circuit supplying power to the crystal counts that this number of oscillations have occurred, it increases the recorded time by one second. This property, of generating an electric current upon the application of mechanical pressure, and vice versa, is known as piezoelectricity (direct and converse). Such crystals were once used in low-end phonograph cartridges: the movement of the stylus (needle) would flex a quartz crystal, which would produce a small voltage, which was amplified and played through speakers.

Many materials can be formed into plates that will resonate. However, since quartz can be directly driven (to flex) by an electric signal, no additional speaker or microphone is required.

Quartz has the further advantage that its size does not change much as temperature fluctuates. Fused quartz is often used for laboratory equipment that must not change shape along with the temperature, because a quartz plate's resonance frequency, based on its size, will not significantly rise or fall. Similarly, a quartz clock will remain relatively accurate as the temperature changes.

Mechanism

In modern quartz clocks, the quartz crystal resonator is in the shape of a small tuning fork, laser-trimmed or precision lapped to vibrate at 32,768 Hz. This frequency is equal to 215 cycles per second. A power of 2 is chosen so a simple chain of digital divide-by-2 stages can derive the 1 Hz signal needed to drive the watch's second hand. In most clocks, the resonator is in a small can or flat package, about 4 mm long. The reason the 32,768 Hz resonator has become so common is due to a compromise between the large physical size of low frequency crystals for watches and the large current drain of high frequency crystals, which reduces the life of the watch battery. During the 1970s, the introduction of metal–oxide–semiconductor (MOS) integrated circuits allowed a 12-month battery life from a single coin cell when driving either a mechanical stepper motor, indexing the second hand (in a quartz analog watch), or a liquid crystal display (in an LCD digital watch). Light-emitting diode (LED) displays for watches have become rare due to their comparatively high battery consumption.

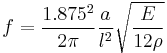

The basic formula for calculating the fundamental frequency (f) of vibration of a cantilever as a function of its dimensions (quadratic cross-section) is:[1]

where

- 1.875 the smallest positive solution of cos(x)cosh(x) = -1 [2]

- l is the length of the cantilever

- a is its thickness along the direction of motion

- E is its Young's modulus

- and ρ is its density

A cantilever made of quartz (E = 1011 N·m−2 = 100 GPa and ρ = 2634 kg·m-3 [3]) with a length of 3 mm and a thickness of 0.3 mm has thus a fundamental frequency of around 33 kHz. The crystal is tuned to exactly 215 = 32,768 Hz or runs at a slightly higher frequency with inhibition compensation (see below).

Accuracy

The relative stability of the resonator and its driving circuit is much better than its absolute accuracy. Standard-quality resonators of this type are warranted to have a long-term accuracy of about 6 parts per million at 31 °C (87.8 °F): that is, a typical quartz wristwatch will gain or lose less than a half second per day at body temperature.

If a quartz wristwatch is "rated" by measuring its timekeeping characteristics against an atomic clock's time broadcast, to determine how much time the watch gains or loses per day, and adjustments are made to the circuitry to "regulate" the timekeeping, then the corrected time will easily be accurate within 10 seconds per year. This is more than adequate to perform celestial navigation.

Some premium clock designs self-rate and self-regulate. That is, rather than just counting vibrations, their computer program takes the simple count, and scales it using a ratio calculated between an epoch set at the factory, and the most recent time the clock was set. These clocks usually have special instructions for changing the battery (the counter must not be permitted to stop), and become more accurate as they age.

It is possible for a computerized clock to measure its temperature, and adjust for that as well. Both analog and digital temperature compensation have been used in high-end quartz watches.

Many inexpensive quartz watches use a technique known as inhibition compensation.[4] The crystal is deliberately made to run somewhat fast, and the digital logic is programmed to skip a small number of crystal cycles at regular intervals such as 10 seconds or one minute. The advantage of this method is that after measuring the frequency of each chip with a precision timer at the factory, storing the number of pulses to suppress in a non-volatile memory register on the chip is less expensive than the older technique of trimming the quartz tuning fork frequency. In more expensive watches, thermal compensation can be implemented by varying the number of cycles to inhibit depending on the output from a temperature sensor. Thermo compensated quartz movements, even in wrist watches, can be accurate to within 10 or 20 seconds per year.[5]

Chronometers

Quartz chronometers designed as time standards often include a crystal oven, to keep the crystal at a constant temperature. Some self-rate and include "crystal farms," so that the clock can take the average of a set of time measurements.

History

The piezoelectric properties of quartz were discovered by Jacques and Pierre Curie in 1880. The first quartz crystal oscillator was built by Walter G. Cady in 1921. In 1923, D. W. Dye at the National Physical Laboratory in the UK and Warren Marrison at Bell Telephone Laboratories produced sequences of precision time signals with quartz oscillators. In 1927, the first quartz clock was built by Warren Marrison and J.W. Horton at Bell Telephone Laboratories.[6][7] The next 3 decades saw the development of quartz clocks as precision time standards in laboratory settings; the bulky delicate counting electronics, built with vacuum tubes, limited their use elsewhere. In January 1932 a quartz clock was able to measure tiny weekly variations in the rotation rate of the Earth.![8] The National Bureau of Standards (now NIST) based the time standard of the US on quartz clocks between the 1930s and the 1960s, then it went to atomic clocks.[9] The wider use of quartz clock technology had to await the development of cheap semiconductor digital logic in the 60s.

The world's first protoype analog quartz wristwatches were revealed in 1967: the Beta 1 revealed by the Centre Electronique Horloger (CEH) in Neuchâtel Switzerland,[10][11] and the prototype of the Astron revealed by Seiko in Japan. (Seiko had been working on quartz clocks since 1958).[10] In 1969, Seiko produced the world's first commercial quartz wristwatch, the Astron.[12] The inherent accuracy and low cost of production has resulted in the proliferation of quartz clocks and watches since that time. By the 1980s, quartz technology had taken over applications such as kitchen timers, alarm clocks, bank vault time locks, and time fuzes on munitions, from earlier mechanical balance wheel movements.

Many traditional European clockmakers, particularly in Switzerland, Germany, France and Russia have continued to produce the less-accurate but still-popular mechanical watches.

Quartz wristwatches are in high demand today as they are more accurate than their mechanical counterparts; they need neither winding nor much maintenance. Light-powered and motion-powered quartz watches represent two innovative types of timepieces. Light-powered quartz watches incorporate a solar cell that transforms the light into electricity. Motion-powered wristwatches have a tiny rotor spinning in response to motion of the wrist, and generating electricity.[13]

See also

References

- ^ Itoh H, Aoshima Y, Sakaguchi Y (2002). "Model for a quartz-crystal tuning fork using plate spring approximated to torsion spring adopted at the joint of the arm and the base". Frequency Control Symposium and PDA Exhibition, 2002. IEEE International: 145–151. doi:10.1109/FREQ.2002.1075871. ISBN 0-7803-7082-1. http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=1075871.

- ^ Whitney, Scott (1999-04-23). "Vibrations of Cantilever Beams: Deflection, Frequency, and Research Uses". University of Nebraska–Lincoln. http://emweb.unl.edu/Mechanics-Pages/Scott-Whitney/325hweb/Beams.htm. Retrieved 2011-11-09.

- ^ "density of quartz - Wolfram|Alpha". Wolframalpha.com. http://www.wolframalpha.com/input/?i=density+of+quartz. Retrieved 2010-03-25.

- ^ Lombardi (2008)

- ^ Read, Alexander. "High accuracy timepieces that could be used as marine chronometer". http://80calcs.pagesperso-orange.fr/Navigation/Chronometer.html. Retrieved 2007-09-22.

- ^ Marrison, W.A.; J.W. Horton (February 1928). "Precision determination of frequency". I.R.E. Proc. 16 (2): 137–154. doi:10.1109/JRPROC.1928.221372.

- ^ Marrison, Warren (1948). "The Evolution of the Quartz Crystal Clock". Bell System Technical Journal (AT&T) 27: 510–588. http://www.ieee-uffc.org/freqcontrol/marrison/Marrison.html.

- ^ (broken link)Marrison, 1948)

- ^ Sullivan, D.B. (2001). "Time and frequency measurement at NIST: The first 100 years". Time and Frequency Division, National Institute of Standards and Technology. p. 5. http://tf.nist.gov/timefreq/general/pdf/1485.pdf.

- ^ a b http://www.ieee-uffc.org/main/history/step.pdf Carlene Stephens and Maggie Dennis Engineering time: inventing the electronic wristwatch

- ^ "From the roots until today's achievements..". Federation of the Swiss Watch Industry. http://www.fhs.ch/en/history.php. Retrieved 2007-12-06.

- ^ Astron

- ^ "Quartz wristwatches". Watches.infoniac.com. 2007-12-11. http://watches.infoniac.com/index.php?page=post&id=48. Retrieved 2010-03-25.

Further reading

- Cook A (2001). "Time and the Royal Society". Notes and Records of the Royal Society of London 55 (1): 9–27. doi:10.1098/rsnr.2001.0123.

- Marrison WA (1948). "The Evolution of the quartz crystal clock". Bell System Technical Journal 27: 510–588. http://www.ieee-uffc.org/freqcontrol/marrison/Marrison.html.