Loading coil

In electronics, a loading coil or load coil is a coil (inductor) that does not provide coupling to any other circuit, but is inserted in a circuit to increase its inductance. The need was discovered by Oliver Heaviside in studying the disappointing slow speed of the Transatlantic telegraph cable. He concluded additional inductance was required to prevent amplitude and time delay distortion of the transmitted signal. The mathematical condition for distortionless transmission is known as the Heaviside condition. Previous telegraph lines were overland or shorter, hence had less delay and the need for extra inductance was not so great. Submarine communications cables are particularly subject to the problem, but early 20th century ones using balanced pairs were often continuously loaded by iron tape rather than discretely by load coils.

Loading coils are archaically known as Pupin coils after Mihajlo Pupin (especially when used for the Heaviside condition), and the process of inserting them is sometimes called pupinization.

Contents |

Applications

Voice circuits

A common application of loading coils is to improve the voice-frequency amplitude response characteristics of the twisted balanced pairs in a telephone cable.

Loading coils inserted periodically in series with a pair of wires reduce the attenuation at the higher voice frequencies up to the cutoff frequency of the low-pass filter formed by the inductance of the coils (plus the distributed inductance of the wires) and the distributed capacitance between the wires. Above the cutoff frequency, attenuation increases rapidly. The shorter the interval between the coils, the higher the cut-off frequency.

It should be emphasised that the cutoff effect is an artifact of using lumped inductors. With loading methods using continuous distributed inductance there is no cutoff.

Without loading coils, the line response is dominated by the resistance and capacitance of the line with the attenuation gently increasing with frequency. With loading coils of exactly the right inductance, neither capacitance nor inductance dominate: the response is flat, waveforms are undistorted and the characteristic impedance is resistive up to the cutoff frequency. The coincidental formation of an audio frequency filter is also beneficial in that noise is reduced.

DSL

When loading coils are in place, signal attenuation remains low for signals within the passband of the transmission line but increases rapidly for frequencies above the audio cutoff frequency. Thus, if the pair is subsequently reused to support applications that require higher frequencies (such as analog or digital carrier systems or DSL), any loading coils that were present on the line must be removed or replaced with one which is transparent to DSL. Using coils with parallel capacitors will form a filter with the topology of an m-derived filter and a band of frequencies above the cut-off will also be passed.

If they are not removed, as when the subscriber is an extended distance (e.g. over 4 miles) from the Central Office, DSL can not be supported. This sometimes happens in dense, growing areas (subject to frequent national numbering scheme repartitioning) such as Southern California in the late 1990s and early 21st century.

Carrier systems

American early and middle 20th Century telephone cables had load coils at intervals of a mile (1.61 km), usually in coil cases holding many. The coils must be removed to pass high frequencies, but the coil cases provided convenient places for repeaters for digital T-carrier systems, which could carry 1.5 Mbit/s across that distance. Due to narrower streets and higher cost of copper, European cables had thinner wires and needed closer intervals. Intervals of a kilometer allowed European systems to carry 2 Mbit/s.

Radio antennae

A (mobile) radio antenna, shorter than a quarter wavelength for practical reasons, presents capacitive reactance to a transmission line. This can be canceled by inserting an equal and opposite (inductive) reactance in series, by means of a loading coil typically at the base or center of the antenna. Consequently the antenna presents a resistance (desirable) to the transmission line.

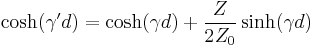

Campbell equation

The Campbell equation is a relationship due to George Ashley Campbell for predicting the propagation constant of a loaded line. It is stated as;[1]

- where,

is the propagation constant of the unloaded line

is the propagation constant of the unloaded line is the propagation constant of the loaded line

is the propagation constant of the loaded line is the interval between coils on the loaded line

is the interval between coils on the loaded line is the impedance of a loading coil and

is the impedance of a loading coil and is the characteristic impedance of the unloaded line.

is the characteristic impedance of the unloaded line.

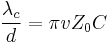

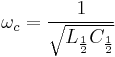

A more engineer friendly rule of thumb is that the approximate requirement for spacing loading coils is ten coils per wavelength of the maximum frequency being transmitted.[2] This approximation can be arrived at by treating the loaded line as a constant k filter and applying image filter theory to it. From basic image filter theory the angular cutoff frequency and the characteristic impedance of a low-pass constant k filter are given by;

and,

and,

- where

and

and  are the half section element values.

are the half section element values.

From these basic equations the necessary loading coil inductance and coil spacing can be found;

and,

and,

- where C is the capacitance per unit length of the line.

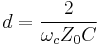

Expressing this in terms of number of coils per cutoff wavelength yields;

- where v is the velocity of propagation of the cable in question.

History

Oliver Heaviside

The origin of the loading coil can be found in the work of Oliver Heaviside on the theory of transmission lines. Heaviside (1881) represented the line as a network of infinitesimally small circuit elements. By applying his operational calculus to the analysis of this network he discovered (1887) what has become known as the Heaviside condition.[3][4] This is the condition that must be fulfilled in order for a transmission down a line to be free from distortion. The Heaviside condition is that the line series impedance, Z, must be proportional to the line shunt admittance, Y, at all frequencies. In terms of the primary line coefficients this is the condition;

- where;

is the series resistance of the line per unit length

is the series resistance of the line per unit length is the series self-inductance of the line per unit length

is the series self-inductance of the line per unit length is the shunt leakage conductance of the line insulator per unit length

is the shunt leakage conductance of the line insulator per unit length is the shunt capacitance between the line conductors per unit length

is the shunt capacitance between the line conductors per unit length

Heaviside was aware that this condition was not met in the practical telegraph cables in use in his day. In general, a real cable would have,

This is mainly due to the low value of leakage through the cable insulator, which is even more pronounced in modern cables which have better insulators than in Heaviside's day. In order to meet the condition, the choices are therefore to try to increase G or L or to decrease R or C. Decreasing R requires larger conductors. Copper was already in use in telegraph cables and this is the very best conductor available short of using silver. Decreasing R means using more copper and a more expensive cable. Decreasing C would also mean a larger cable (although not necessarily more copper). Increasing G is highly undesirable, while it would reduce distortion, it would at the same time increase the signal loss. Heaviside considered, but rejected, this possibility which left him with the strategy of increasing L as the way to reduce distortion.[5]

Heaviside immediately (1887) proposed several methods of increasing the inductance, including spacing the conductors further apart and loading the insulator with iron dust. Finally, Heaviside made the proposal (1893) to use discrete inductors at intervals along the line.[6] However, he never succeeded in persuading the British GPO to take up the idea. Brittain attributes this to Heaviside's failure to provide engineering details on the size and spacing of the coils for particular cable parameters. Heaviside's eccentric character and setting himself apart from the establishment may also have played a part in their ignoring of him.[7]

John Stone

John S. Stone worked for the American Telephone & Telegraph Company (AT&T) and was the first to attempt to apply Heaviside's ideas to real telecommunications. Stone's idea (1896) was to use a bimetallic iron-copper cable which he had patented.[8] This cable of Stone's would increase the line inductance due to the iron content and had the potential to meet the Heaviside condition. However, Stone left the company in 1899 and the idea was never implemented.[9]

George Campbell

George Campbell was another AT&T engineer working for them in their Boston facility. Campbell was tasked with continuing the investigation into Stone's bimetallic cable, but soon abandoned this in favour of the loading coils idea. This was an independent discovery, Campbell being aware of Heaviside's work in discovering the Heaviside condition, but apparently not aware of Heaviside's suggestion of using loading coils to force a line to meet it. The motivation for the change of direction was Campbell's limited budget.

Campbell was struggling to set up a practical demonstration over a real telephone route with the budget he had been allocated. After considering that his artificial line simulators used lumped components rather than the distributed quantities found in a real line, he wondered if he could not insert the inductance with lumped components instead of using Stone's distributed line. When his calculations showed that the manholes on telephone routes were sufficiently close together to be able to insert the loading coils without the expense of either having to dig up the route or lay in new cables he changed to this new plan.[10] The very first demonstration of loading coils on a telephone cable was on a 46-mile length of the so-called Pittsburgh cable (the test was actually in Boston, the cable had previously been used for testing in Pittsburgh) on September 6, 1899 carried out by Campbell himself and his assistant.[11] The first telephone cable using loaded lines put into public service was between Jamaica Plain and West Newton in Boston on May 18, 1900.[12]

Campbell's work on loading coils provided the theoretical basis for his subsequent work on filters which proved to be so important for frequency-division multiplexing. The cut-off phenomena of loading coils, an undesirable side-effect, can be exploited to produce a desirable filter frequency response.[13][14]

Michael Pupin

Michael Pupin, inventor and Serbian immigrant to the USA, also played a part in the story of loading coils. Pupin filed a rival patent to the one of Campbell's.[15] This patent of Pupin's dates from 1899. There is an earlier patent[16] (1894, filed December 1893) which is sometimes cited as Pupin's loading coil patent but is, in fact, something different. The confusion is easy to understand, Pupin himself claims that he first thought of the idea of loading coils while climbing a mountain in 1894,[17] although there is nothing from him published at that time.[18]

Pupin's 1894 patent "loads" the line with capacitors rather than inductors, a scheme that has been criticised as being theoretically flawed[19] and never put into practice. To add to the confusion, one variant of the capacitor scheme proposed by Pupin does indeed have coils. However, these are not intended to compensate the line in any way. They are there merely to restore DC continuity to the line so that it may be tested with regular equipment. Pupin states that the inductance is to be so large that it will block all AC signals above 50 Hz.[20] Consequently, only the capacitor is adding any significant impedance to the line and "the coils will not exercise any material influence on the results before noted".[21]

Legal battle

Heaviside never patented his idea; indeed, he took no commercial advantage of any of his work.[22] Despite the legal disputes surrounding this invention, it is unquestionable that Campbell was the first to actually construct a telephone circuit using loading coils.[23] There also can be little doubt that Heaviside was the first to publish and many would dispute Pupin's priority.[24][25][26]

AT&T fought a legal battle with Pupin over his claim. Pupin was first to patent but Campbell had already conducted practical demonstrations before Pupin had even filed his patent (December 1899).[27] Campbell's delay in filing was due to the slow internal machinations of AT&T.[28]

However, AT&T foolishly deleted from Campbell's proposed patent application all the tables and graphs detailing the exact value of inductance that would be required before the patent was submitted.[29] Since Pupin's patent contained a (less accurate) formula, AT&T was open to claims of incomplete disclosure. Fearing that there was a risk that the battle would end with the invention being declared unpatentable due to Heaviside's prior publication, they decided to desist from the challenge and buy an option on Pupin's patent for a yearly fee so that AT&T would control both patents. By January 1901 Pupin had been paid $200,000 and by 1917, when the AT&T monopoly ended and payments ceased, he had received a total of $455,000.[30]

Benefit to AT&T

The invention was of enormous value to AT&T. Telephone cables could now be used to twice the distance previously possible, or alternatively, a cable of half the previous quality (and cost) could be used over the same distance. When considering whether to allow Campbell to go ahead with the demonstration, their engineers had estimated that they stood to save $700,000 in new installation costs in New York and New Jersey alone.[31] It has been estimated that AT&T saved $100 million in the first quarter of the 20th century.[32][33] Heaviside, who began it all, came away with nothing. He was offered a token payment but would not accept, wanting the credit for his work. He remarked ironically that if his prior publication had been admitted it would "interfere . . . with the flow of dollars in the proper direction . . .".[34]

Krarup cable

Loading coils were not without their problems. For submarine cables where they were of most benefit, they were difficult to lay. The cable needed to be heavier and both this and the discontinuities in the profile where the coils occurred caused stresses in the cable during laying. Without great care, the cable might part and would be enormously expensive, possibly impossible, to fix. A second problem was that the material science of the time had difficulties sealing the joint between coil and cable against ingress of seawater. When this occurred, of course, the cable was ruined.[35]

A Danish engineer, Carl Emil Krarup, invented a form of continuously loaded cable which solved these problems and the cable is named for him. Krarup cable has iron wires continuously wound around the central copper conductor with adjacent turns in contact with each other. This cable was the first use of continuous loading on any telecommunication cable.[36] In 1902 Krarup both wrote his paper on this subject and saw the installation of the first cable between Helsingør (Denmark) and Helsingborg (Sweden).[37]

Permalloy cable

Even though Krarup cable added inductance to the line, it did not add enough to meet the Heaviside condition. AT&T searched for a better material with higher magnetic permeability. In 1914 Gustav Elmen discovered permalloy, a magnetic nickel-iron annealed alloy. Oliver E. Buckley, along with his colleagues at Bell Labs, H. D. Arnold and Elmen, c.1915 proposed a method of constructing submarine cable using permalloy tape wrapped around the copper conductors. This construction greatly improved the performance of the cable.[38]

The cable was tested in a trial in Bermuda in 1923. The first permalloy cable to be put into service was between New York and Horta (Azores) in September 1924.[38] Permalloy cable enabled signalling speed on submarine telegraph cables to be increased to 2,000 words/min at a time when 40 words/min was considered good.[39]

Mu-metal cable

Mu-metal has similar magnetic properties to permalloy but the addition of copper to the alloy increases the ductility and allows the metal to be drawn into wire. Mu-metal cable is easier to construct than permalloy cable, the mu-metal being wound around the core copper conductor in much the same way as the iron wire in Krarup cable. A further advantage with mu-metal cable is that the construction lends itself to a variable loading profile whereby the loading is tapered towards the ends.

Mu-metal was invented (1923) by The Telegraph Construction and Maintenance Company Ltd., London,[40] who made the cable, initially, for the Western Union Telegraph Co. Western Union were in competition with AT&T and the Western Electric Company who were using permalloy (the patent for permalloy was held by Western Electric). [41]

Current practice

Loaded cable is no longer a useful technology for submarine communication cables, having first been superseded by co-axial cable using electrically powered in-line repeaters and then by fibre-optic cable. Manufacture of loaded cable declined in the 1930s and was then superseded by other technologies post-war. Loading coils can still be found in some telephone landlines today but new installations would use more modern technology.

Notes

- ^ Brittain, p43

- ^ Brittain, p42

- ^ Heaviside, O, "Electromagnetic Induction and its propagation", The Electrician, 3 June 1887.

- ^ Heaviside, O, Electrical Papers, vol 1, pp139-140, Boston, 1925.

- ^ Brittain, pp39-40

- ^ The Electrician, 1887 and reproduced (according to Brittain) in Heaviside, O, Electromagnetic Theory, p112

- ^ Brittain, p40

- ^ Stone, M S, Electric Circuit, US patent 0 578 275, filed 10 September 1896, issued 2 March 1897.

- ^ Brittain pp40-41

- ^ Brittain, pp42-45

- ^ Brittain, pp43-44

- ^ Brittain p45

- ^ Campbell, G A, "Physical Theory of the Electric Wave-Filter", Bell System Tech J, November 1922, vol 1, no 2, pp 1-32.

- ^ Brittain, p56

- ^ Pupin, M, Art of Reducing Attenuation of Electrical Waves and Apparatus Therefor, US patent 0 652 230, filed 14 December 1899, issued 19 June 1900.

- ^ Pupin, M, Apparatus for Telegraphic of Telephonic Transmission, US patent 0 519 346, filed 14 December 1893, issued 8 May 1894.

- ^ Pupin, M I, From Immigrant to Inventor, pp330-331, Charles Schribner & Sons, 1924

- ^ Brittain, p46

- ^ Britain, p46, quoting a contemporary criticism in Electrical Review and experiments by the GPO showing that the scheme does not work

- ^ Pupin, 1894, p5 lines 75-83

- ^ Pupin, 1894, p5 lines 123-125

- ^ Bray, p53

- ^ Brittain p56

- ^ Brittain, p36, 48-50

- ^ Brittain, p37, quoting a letter Behrend to Searle

- ^ Brittain, p37, quoting a letter Searle to Behrend, 1931

- ^ Pupin, M I, Art of Reducing Attenuation of Electrical Waves and Apparatus Therefore, US patent 0 652 230, filed 14th December 1899, issued 19th June 1900.

- ^ Brittain, p44

- ^ Brittain p44-45

- ^ Brittain, p54, p55 (footnote), p57

- ^ Brittain, p45

- ^ Brittain, p36

- ^ Shaw, T & Fondiller, W, "Developments and Applications of Loading for Telephone Circuits", Transactions of the American Institute of Electrical Engineers, vol 45, pp291-292, 1926.

- ^ Brittain quoting Heaviside letter to Behrend, 1918.

- ^ Britannica, 1911

- ^ Kragh, p129

- ^ Huurderman, pp321-322

- ^ a b Huurdeman, p.314

- ^ Huurdeman, p.308

- ^ Smith, WS, Garnett, HJ, New and improved magnetic alloys, and their application in the manufacture of telegraphic and telephonic cables, Patent GB224972, filed 25th Aug 1923, issued 25th Nov 1925. patented in the US as US1582353 and US1552769

- ^ Allan Green, "150 Years Of Industry & Enterprise At Enderby's Wharf" paper presented at University College, July 2004, for History of the Atlantic Cable & Undersea Communications retrieved 16th January 2009.

See also

References

- Bray, J, Innovation and the Communications Revolution, Institute of Electrical Engineers, 2002.

- James E. Brittain, "The Introduction of the Loading Coil: George A. Campbell and Michael I. Pupin", Technology and Culture, Vol. 11, No. 1 (Jan., 1970), pp. 36–57, The Johns Hopkins University Press on behalf of the Society for the History of Technology.

- Heaviside, O, Electrical Papers, American Mathematical Society Bookstore, 1970 (reprint from 1892).

- Huurdeman, AA, The worldwide history of telecommunications, Wiley-IEEE, 2003

- Kragh, H, "The Krarup Cable: Invention and Early Development", Technology and Culture, Vol. 35, No. 1 (Jan., 1994), pp. 129–157, Published by: The Johns Hopkins University Press on behalf of the Society for the History of Technology

- This article incorporates public domain material from the General Services Administration document "Federal Standard 1037C" (in support of MIL-STD-188).