Lubrication theory

In fluid dynamics, lubrication theory describes the flow of fluids (liquids or gases) in a geometry in which one dimension is significantly smaller than the others.

Interior flows are those where the boundaries of the fluid volume are known, and include those inside bearings. Here a key goal of lubrication theory is to determine the pressure distribution in the fluid volume, and hence the forces on the bearing components. The working fluid in this case is often termed a lubricant.

Free film lubrication theory is concerned with the case in which one of the surfaces containing the fluid is a free surface. In that case the position of the free surface is itself unknown, and one goal of lubrication theory is then to determine this. Surface tension may then be significant, or even dominant. Issues of wetting and dewetting then arise. For very thin films (thickness less than one micrometre), additional intermolecular forces, such as disjoining forces, may become significant.

Contents |

Theoretical basis

Mathematically, lubrication theory can be seen as exploiting the disparity between two length scales. The first is the characteristic film thickness,  , and the second is a characteristic substrate length scale

, and the second is a characteristic substrate length scale  . The key requirement for lubrication theory is that the ratio

. The key requirement for lubrication theory is that the ratio  is small, that is,

is small, that is,  . The Navier-Stokes equations (or Stokes equations, when fluid inertia may be neglected) are expanded in this small parameter, and the leading-order equations are then

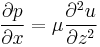

. The Navier-Stokes equations (or Stokes equations, when fluid inertia may be neglected) are expanded in this small parameter, and the leading-order equations are then

where  and

and  are coordinates in the direction of the substrate and perpendicular to it respectively. Here

are coordinates in the direction of the substrate and perpendicular to it respectively. Here  is the fluid pressure, and

is the fluid pressure, and  is the fluid velocity component parallel to the substrate;

is the fluid velocity component parallel to the substrate;  is the fluid viscosity.

is the fluid viscosity.

Further details can be found in the literature[1] or in the textbooks given in the bibliography.

Applications

An important application area is lubrication of machinery components such as fluid bearings and mechanical seals. Coating is another major application area including the preparation of thin films, printing, painting and adhesives.

Biological applications have included studies of red blood cells in narrow capillaries and of liquid flow in the lung and eye.

Notes

- ^ Oron, A; Davis S. H., and S. G. Bankoff, "Long-scale evolution of thin liquid films", Rev. Mod. Phys. 69, 931 - 980 (1997)

References

- Batchelor, G. K. (1976), An introduction to fluid mechanics, Cambridge: CUP. ISBN 978-0-52-109817-5.

- Panton, R. L. (2005), Incompressible Flow (3rd ed.), New York: Wiley . ISBN 978-0-47-126122-3.

- San Andres, L., MEEN334 Mechanical Systems Course Notes [1].