Goniometer

A goniometer is an instrument that either measures an angle or allows an object to be rotated to a precise angular position. The term goniometry is derived from two Greek words, gōnia, meaning angle, and metron, meaning measure.

Contents |

Applications

Communications

Goniometers are used for direction finding in signals intelligence applications for military and civil purposes,[1] e.g. interception of satellite and naval communications as performed on the French warship Dupuy de Lôme uses multiple goniometers.

Crystallography

In crystallography, goniometers are used for measuring angles between crystal faces. They are also used in X-ray diffraction to rotate the samples. The groundbreaking investigations of physicist Max von Laue and cohorts into the atomic structure of crystals in 1912 involved a goniometer.

Light measurement

Goniophotometers measure the spatial distribution of light visible to the human eye at a specific angular position.

In Medicine

Medical practitioners, (Physicians, Physician Assistants, Physical Therapists, Athletic Trainers, Chiropractors and Nurse Practitioners) use a goniometer to document initial and subsequent range of motion, at the visits for Occupational injuries, and by disability evaluators to determine a permanent disability. This is to evaluate progress, and also for medico-legal purposes. It is a tool to evaluate Waddell's signs (findings that may indicate symptom magnification.)

Physical therapy

In physical therapy and occupational therapy, a goniometer is an instrument which measures an axis and range of motion. If a patient or client experiences decreased range of motion in a joint (e.g. a knee or elbow), the therapist can use a goniometer to assess what the range of motion is prior to intervention, and then make sure the intervention is working by using the goniometer in subsequent interventions.

Surface science

In surface science, an instrument generally called a contact angle goniometer is used to measure the static contact angle, advancing & receding contact angles, and surface tension. The first contact angle goniometer was designed by Dr. William Zisman of the United States Naval Research Laboratory in Washington, DC and manufactured by ramé-hart (now ramé-hart instrument company), New Jersey, USA. The original manual contact angle goniometer used an eyepiece with microscope. The current generation of contact angle instruments uses cameras and software to capture and analyze the drop shape and are better suited for dynamic and advanced studies. A Gonioreflectometer is used to measure the reflectivity of a surface at a variety of angles.

Static contact angle

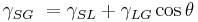

The contact angle, θ, is the angle formed by a liquid at the three phase boundary where the liquid, gas, and solid intersect. The contact angle depends on the interfacial tensions between the gas & liquid, liquid & solid, and gas & solid. Young’s Relation expresses the contact angle analytically.[2]

where

= Interfacial tension between the solid and gas

= Interfacial tension between the solid and gas = Interfacial tension between the solid and liquid

= Interfacial tension between the solid and liquid = Interfacial tension between the liquid and gas

= Interfacial tension between the liquid and gas

Contact angle goniometers measure a droplet’s contact angle by assuming the droplet fits the geometry of a sphere, ellipsoid, or the Young-Laplace equation.

Another perspective that describes contact angles uses cohesion vs. adhesion. Cohesion is the force between the liquid molecules which hold the liquid together. Adhesion is the force between the liquid molecules and the solid molecules. The contact angle is a quantitative measure that tells the user the ratio of cohesion vs. adhesion. If the contact angle is near zero, meaning the liquid droplet spreads completely on the solid surface, adhesive forces are dominating. If the contact angle is very high, meaning the liquid droplet beads up on the solid surface as water does on a freshly waxed car, cohesive forces are dominating.

Advancing and receding contact angles

While static contact angles give static information about the interfacial tensions between the solid, liquid, and gas, advancing and receding contact angles give some information about the dynamic interaction of the liquid, solid, and gas. An advancing contact angle is determined by pushing a droplet out of a pipette onto a solid. When the liquid initially meets the solid it will form some contact angle. As the pipette injects more liquid through the pipette, the droplet will increase in volume, the contact angle will increase, but its three phase boundary will remain stationary until it suddenly jumps outward. The contact angle the droplet had immediately before jumping outward is termed the advancing contact angle. The receding contact angle is now measured by sucking the liquid back out of the droplet. The droplet will decrease in volume, the contact angle will decrease, but its three phase boundary will remain stationary until it suddenly jumps inward. The contact angle the droplet had immediately before jumping inward is termed the receding contact angle. The difference between advancing and receding contact angles is termed contact angle hysteresis which can be used to characterize surface heterogeneity, roughness, and mobility.[3] Surfaces that are not homogeneous will have domains which impede motion of the contact line.

Surface tension

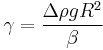

Contact angle goniometers can also determine the surface tension for any liquid in gas or the interfacial tension between any two liquids. If the difference in densities between the two fluids is known, the surface tension or interfacial tension can be calculated by using the pendant drop method. Surface tension quantifies the cohesive force present at the surface of a droplet. Contact angle goniometers measure surface tension by examining a drop hanging from a syringe tip in air. The balance of forces acting on the drop include the surface tension. The surface tension can be calculated using the below equation

where:

is the liquid-air surface tension (J/m² or N/m)

is the liquid-air surface tension (J/m² or N/m)- β is the shape factor

- Δρ is the difference in density between fluids at the interface (kg/m3)

- g is acceleration due to gravity (m/s²)

- R is the radius of the drop curvature at the drop’s apex (m)

3 dimensionless first order equations can define the shape factor

- dx/ds = cosθ

- dz/ds = sinφ

- dφ/ds = 2 + βz – sinφ/x

Iterative approximations can solve for β.

Positioning

A positioning goniometer or goniometric stage is a device used to rotate an object precisely about a fixed axis in space. It is similar to a linear stage, however, rather than moving linearly with respect to its base, the stage platform rotates partially about a fixed axis above the mounting surface of the platform. Positioning goniometers typically use a worm drive with a partial worm wheel fixed to the underside of the stage platform meshing with a worm in the base. The worm may be rotated manually or by a motor as in automated positioning systems.

Knife and blade cutting edge angle measurement

The included cutting angles of all kinds of sharp edge blades is measured using a laser reflecting goniometer. Developed by CATRA in the UK, a range of devices can accurately determine the cutting edge profile including a rounding of the tip to ½°. The included angle of a blade is important in controlling its cutting ability and edge strength, i.e. a low angle makes the edge thin and optimized for cutting while a large angle makes it thick, which cuts poorly, but is very strong.

See also

References

- ^ Jacqueline Boucher (2007-05-03). "Radio receiver workload accelerates". http://www.army.mil/-news/2007/05/03/2975-radio-receiver-workload-accelerates/. Retrieved 2007-09-21.

- ^ Young, T. (1805). "An Essay on the Cohesion of Fluids". Phil. Trans. R. Soc. Lond. 95: 65–87. doi:10.1098/rstl.1805.0005.

- ^ KSV Instruments. Operation Manual for Contact Angle Goniometer.