Federal Bridge Gross Weight Formula

The Federal Bridge Gross Weight Formula (also known as Bridge Formula B and the Federal Bridge Formula) is a mathematical formula in use in the United States by truck drivers and Department of Transportation (DOT) officials to determine the appropriate maximum gross weight for a commercial motor vehicle (CMV) based on axle number and spacing. The formula is part of federal weight and size regulations regarding interstate commercial traffic (intrastate traffic is subject to state limits). The formula is necessary to prevent heavy vehicles from damaging roads and bridges. CMVs are most often tractor-trailers or buses, but the formula is of most interest to truck drivers due to the heavy loads their vehicles often carry.

Early 20th-century weight limits were enacted to protect dirt and gravel roads from damage caused by the solid wheels of heavy trucks. As time passed, truck weight limits focused primarily on gross weight limits (which had no prescribed limits on length). By 1974, bridges received special protection from increasing truck weight limits. The bridge formula law was enacted by the U.S. Congress to limit the weight-to-length ratio of heavy trucks, and to protect roads and bridges from the damage caused by the concentrated weight of shorter trucks. The formula effectively lowers the legal weight limit for shorter trucks, preventing them from causing premature deterioration of bridges and highway infrastructure.

Compliance with the law is checked when vehicles pass through a weigh station, often located at the borders between states or on the outskirts of major cities, where the vehicle may be weighed and measured. The one exception to the formula allows a standard five-axle semi-truck configuration to weigh the maximum legal gross weight. This exception was specifically requested by the American Trucking Associations to allow tank trucks to reach the maximum legal gross weight without violating the bridge formula law.

Contents |

History

The first truck weight limits were enacted by four states in 1913, ranging from 18,000 pounds (8,200 kg) in Maine to 28,000 pounds (13,000 kg) in Massachusetts. These laws were passed to protect earth and gravel-surfaced roads from damage caused by the steel and solid rubber wheels of early heavy trucks. By 1933, all states had some form of truck weight regulation. The Federal-Aid Highway Act of 1956 instituted the first federal truck weight regulation (set at 73,280 pounds / 33,240 kilograms) and authorized the construction of the Interstate Highway System.[2]

In the late 1950s, the American Association of State Highway and Transportation Officials (AASHTO) conducted a series of extensive field tests of roads and bridges to determine how traffic contributed to the deterioration of pavement materials. In 1964, the AASHTO recommended to Congress that a bridge formula table be used instead of a single gross weight limit for trucks. The Federal-Aid Highway Act Amendments of 1974 established the bridge formula as law, along with the gross weight limit of 80,000 pounds (36,000 kg), still in use as of 2009.[2]

Usage

The formula was enacted as law to limit the weight-to-length ratio of a commercial motor vehicle (CMV).[3] The formula is necessary to prevent the concentrated weight on a truck's axle from producing stress on bridge members (possibly causing a bridge collapse).[4] In simplified form, this is analogous to a person walking on thin ice. When standing upright, a person's weight is concentrated at the bottom of their feet, funneling all of their weight into a small area. When lying down, a person's weight is distributed over a much larger area. This difference in weight distribution would allow a person to cross an area of ice while crawling that might otherwise collapse under their body weight while standing up. For an overweight truck to comply with the formula, more axles must be added, the distance between axles must be increased, or weight must be removed.[1][5]

A division of the DOT, the Federal Motor Carrier Safety Administration (FMCSA), regulates safety for the U.S. trucking industry.[6] The FMCSA regulates the length, width, and weight limits of CMVs for interstate commercial traffic. Interstate commercial traffic is generally limited to a network of Interstate Highways, U.S. highways, and state highways known as the National Network (NN). Provided the truck remains on the NN, it is not subject to state limits. These limits (which can be lower or higher than federal limits) come into effect for intrastate commercial traffic, provided the vehicle is not on the NN.[7]

CMVs are defined by the FMCSA as vehicles engaged in interstate commerce that are used to transport passengers or property: vehicles with a gross vehicle weight of 10,001 pounds (4,536 kg) or more; those designed or used to transport more than 8 passengers (including the driver) for compensation; vehicles designed or used to transport more than 15 passengers (including the driver) without compensation; or those used to transport hazardous materials in quantities requiring the vehicle to be marked or placarded under hazardous materials regulations.[8]

The weight and size of CMVs are restricted for practical and safety reasons. CMVs are restricted by gross weight (total weight of vehicle and cargo), and by axle weight (i.e., the weight carried by each tire). The federal weight limits for CMVs are 80,000 pounds (36,000 kg) for gross weight (unless the bridge formula dictates a lower limit), 34,000 pounds (15,000 kg) for a tandem axle, and 20,000 pounds (9,100 kg) for a single axle.[9] A tandem axle is defined as two or more consecutive axles whose centers are spaced more than 40 inches (100 cm) but not more than 96 inches (240 cm) apart.[8] Axles spaced less than 40 inches (100 cm) apart are considered a single axle.[10]

In effect, the formula reduces the legal weight limit for shorter trucks with fewer axles (see table below). For example, a 25-foot (7.6 m) three-axle dump truck would have a gross weight limit of 54,500 pounds (24,700 kg), instead of 80,000 pounds (36,000 kg), which is the standard weight limit for 63-foot (19 m) five-axle tractor-trailer.[1] FMCSA regulation §658.17 states: "The maximum gross vehicle weight shall be 80,000 pounds except where lower gross vehicle weight is dictated by the bridge formula."[9]

Bridge collapse

The August 2007 collapse of the Interstate 35W Mississippi River bridge in Minneapolis brought renewed attention to the issue of truck weights and their relation to bridge stress.[12] In November 2008, the National Transportation Safety Board determined several reasons for the bridge's collapse, including (but not limited to): faulty gusset plates, inadequate inspections, and the extra weight of heavy construction equipment combined with the weight of rush hour traffic.[13] Reports suggest that as early as 1998, the Federal Highway Administration (FHWA) expressed concern over bridges on the I-35 corridor due to an expected increase of international truck traffic from Canada and Mexico.[14]

As of 2007, federal estimates suggest truck traffic increased 216% since 1970, shortly before the federal gross weight limit for trucks was increased by 30,000 pounds (14,000 kg). This is also the period during which many of the existing interstate bridges were built. Research shows that increased truck traffic (and therefore, increased stress) shortens the life of bridges.[12] National Pavement Cost Model (NAPCOM) estimates indicate that one 80,000-pound (36,000 kg) truck does as much damage to roads as 750 3,800-pound (1,700 kg) cars.[15]

Some smaller bridges have a weight limit (or gross weight load rating) indicated by a sign posted in a visible position in front of the bridge (hence the reference to a "posted bridge"). These are necessary when the weight limit of the bridge is lower than the federal or state gross weight limit for trucks.[11][16] Driving a truck over a bridge that is too weak to support it usually does not result in an immediate collapse. The bridge may develop cracks, which over time can weaken the bridge and cause it to collapse. Most of these cracks are discovered during mandated inspections of bridges. Most bridge collapses occur in rural areas, result in few injuries or deaths, and receive relatively little media attention. While the number varies from year to year, as many as 150 bridges can collapse in a year. About 1,500 bridges collapsed between 1966 and 2007, and most of those were the result of soil erosion around bridge supports.[17][18] In 1987, the Schoharie Creek Bridge collapsed in upstate New York, due to erosion of soil around the foundation, which sparked renewed interest in bridge design in inspection procedures.[19]

In special cases involving unusually overweight trucks (which require special permits), not observing a bridge weight limit can lead to disastrous consequences. Fifteen days after the collapse of the Minneapolis bridge, a heavy truck collapsed a small bridge in Oakville, Washington.[20]

Formula law

CMVs are required to pass through weigh stations at the borders of most states and some large cities. These weigh stations are run by state DOTs, and CMV weight and size enforcement is overseen by the FHWA. Weigh stations check each vehicle's gross weight and axle weight using a set of in-ground truck scales, and are usually where a truck's compliance with the formula is checked.[21]

FMCSA regulation §658.17 states:[9]

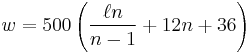

- No vehicle or combination of vehicles shall be moved or operated on any interstate highway when the gross weight on two or more consecutive axles exceeds the limitations prescribed by the following formula:

- w = the maximum weight in pounds that can be carried on a group of two or more axles to the nearest 500 pounds (230 kg).

- ℓ = spacing in feet between the outer axles of any two or more consecutive axles.

- n = number of axles being considered.

Two or more consecutive axles may not exceed the weight computed by the bridge formula, even if the gross weight of the truck (or the weight on one axle) is below otherwise legal limits.[3] Although this means that any two axles must comply with the formula, experience has shown that axles 1 through 3, 1 through 5, and 2 through 5 are critical and must be checked. This means that the axle group which comprises the entire truck (known as the "outer group") and the interior axle groups (known as the "tractor group" and "trailer group") must also comply with the bridge formula. If these combinations are found to be satisfactory, then all of the other axle groups on this type of vehicle will usually be satisfactory.[1]

Penalties for violating weight limits vary between states (bridge formula weight violations are treated as gross weight violations), as the states are responsible for enforcement and collection of fines. Some states, such as Connecticut, issue fines on a percentage basis (e.g. 20% overweight at $10 per 100 pounds / 45 kilograms), which means larger trucks pay higher fines. For example, a truck with a legal gross limit of 20,000 pounds (9,100 kg) that violates the limit by 5,000 pounds (2,300 kg) would pay a fine of $500, while a truck with a legal gross limit of 60,000 pounds (27,000 kg) that violates the limit by 5,000 pounds would pay a fine of $250. Other states, such as New York, issue fines on a per-pound basis (e.g., 5,000 pounds overweight equals a $300 fine). Others, such as Massachusetts, impose a less complicated fine schedule whereby a vehicle that violates the limits by less than 10,000 pounds (4,500 kg) is fined $40 per 1000 pounds, while a violation over 10,000 pounds pays $80 per 1000 pounds (e.g. 5,000 pounds overweight equals a $200 fine).[22]

Some states require overweight trucks to offload enough cargo to comply with the limits. In Florida, any vehicle that exceeds the limits by more than 6,000 pounds (2,700 kg) is required to be unloaded until the vehicle is in compliance. Florida also includes a scale tolerance, which allows for violations of less than 10% to be forgiven, and no fine issued. Florida also allows for a load to be shifted (e.g., moved from the front towards the rear of the vehicle) for the vehicle to comply with axle weight limits, without penalty.[23]

Exception

There is one exception to the formula: two consecutive sets of tandem axles may carry 34,000 pounds (15,000 kg) each if the overall distance between the first and last axles of these tandems is 36 feet (11 m) or more. For example, a five-axle truck may carry 34,000 pounds both on the tractor tandem axles (2 and 3) and the trailer tandem axles (4 and 5), provided axles 2 and 5 are spaced at least 36 feet (11 m) apart.[1]

This exception allows for the standard 5-axle semi-truck configuration to gross up to 80,000 pounds (36,000 kg) (the legal limit)[9] without being in violation of the bridge formula law. Without it, the bridge formula would allow an actual weight of only 66,000 pounds (30,000 kg) to 67,500 pounds (30,600 kg) on tandems spaced 36 feet (11 m) to 38 feet (12 m) apart; compared to 68,000 pounds (31,000 kg) with the exception. This exception was sought by the American Trucking Associations so trucking companies could use 40-foot (12 m) trailers and weigh 80,000 pounds (36,000 kg). It was the only way tank truck operators could reach 80,000 pounds without adding axles to their fleets of trailers already in operation.[24]

A CMV may exceed the bridge formula limits (or gross weight and axle weight limits) by up to 400 pounds (180 kg) if the vehicle is equipped with an auxiliary power unit (APU) or idle reduction technology. According to the FMCSA, this is permitted "in order to promote reduction of fuel use and emissions because of engine idling". To be eligible, the vehicle's operator must prove the weight of the APU with written certification, or—by demonstration or certification—that the idle reduction technology is fully functional at all times. Certification of the APU's weight must be available to law enforcement officers if the vehicle is found in violation of applicable weight laws. The additional weight allowed cannot exceed 400 pounds or the weight certified, whichever is less.[9]

Issues

The bridge formula (also referred to as Formula B) is based on research into single-span bridges, and fails to consider multiple-span bridges. Two-span bridges may not be fully protected by Formula B, depending on the truck length, span length, and other factors.[25] Shorter wheelbase vehicles (usually specialized trucks such as garbage trucks and water trucks) have trouble complying with Formula B.[26]

In 1987, the U.S. Congress passed the Surface Transportation and Uniform Relocation Assistance Act, requesting the Transportation Research Board (TRB) to conduct a study to develop alternatives to Formula B. The study recommended several that were never implemented. It suggested that Formula B was too strict for trucks with shorter axle lengths. One of the alternative formulas (later known as the TTI HS-20 Bridge Formula) was developed in conjunction with the Texas Transportation Institute. TTI HS-20 allowed shorter trucks to have higher weight limits than Formula B. For a 3-axle truck with an axle length of 14 feet (4.3 m), the weight limit increased from 46,500 pounds (21,100 kg) to 54,000 pounds (24,000 kg).[26] TTI HS-20 also failed to address the problem of multiple-span bridges.[25]

Bridge formula table

| Distance in feet between any group of two or more axles 1 |

Gross weight in pounds 2 | |||||

|---|---|---|---|---|---|---|

| 2 axles | 3 axles | 4 axles | 5 axles | 6 axles | 7 axles | |

| Less than 8 3 | 34,000 | 34,000 | ||||

| More than 8 4 | 38,000 | 42,000 | ||||

| 9 | 39,000 | 42,500 | ||||

| 10 | 40,0005 | 43,500 | ||||

| 11 | 40,000 | 44,000 | ||||

| 12 | 40,000 | 45,000 | 50,000 | |||

| 13 | 40,000 | 45,000 | 50,500 | |||

| 14 | 40,000 | 46,500 | 51,500 | |||

| 15 | 40,000 | 47,000 | 52,000 | |||

| 16 | 40,000 | 48,000 | 52,500 | 58,000 | ||

| 17 | 40,000 | 48,500 | 53,500 | 58,500 | ||

| 18 | 40,000 | 49,500 | 54,000 | 59,000 | ||

| 19 | 40,000 | 50,500 | 54,500 | 60,000 | ||

| 20 | 40,000 | 51,000 | 55,500 | 60,500 | 66,000 | |

| 21 | 40,000 | 51,500 | 56,000 | 61,000 | 66,500 | |

| 22 | 40,000 | 52,500 | 56,500 | 61,500 | 67,000 | |

| 23 | 40,000 | 53,000 | 57,500 | 62,500 | 68,000 | |

| 24 | 40,000 | 54,000 | 58,000 | 63,000 | 68,500 | 74,000 |

| 25 | 40,000 | 54,500 | 58,500 | 63,500 | 69,000 | 74,500 |

| 26 | 40,000 | 55,500 | 59,500 | 64,000 | 69,500 | 75,000 |

| 27 | 40,000 | 56,000 | 60,000 | 65,000 | 70,000 | 75,500 |

| 28 | 40,000 | 57,000 | 60,500 | 65,500 | 71,000 | 76,500 |

| 29 | 40,000 | 57,500 | 61,500 | 66,000 | 71,500 | 77,000 |

| 30 | 40,000 | 58,500 | 62,000 | 66,500 | 72,000 | 77,500 |

| 31 | 40,000 | 59,000 | 62,500 | 67,500 | 72,500 | 78,000 |

| 32 | 40,000 | 60,0005 | 63,500 | 68,000 | 73,000 | 78,500 |

| 33 | 40,000 | 60,000 | 64,000 | 68,500 | 74,000 | 79,000 |

| 34 | 40,000 | 60,000 | 64,500 | 69,000 | 74,500 | 80,0005 |

| 35 | 40,000 | 60,000 | 65,500 | 70,000 | 75,000 | 80,000 |

| 36 | 40,000 | 60,000 | 66,0006 | 70,500 | 75,500 | 80,000 |

| 37 | 40,000 | 60,000 | 66,5006 | 71,000 | 76,000 | 80,000 |

| 38 | 40,000 | 60,000 | 67,5006 | 71,500 | 77,000 | 80,000 |

| 39 | 40,000 | 60,000 | 68,000 | 72,500 | 77,500 | 80,000 |

| 40 | 40,000 | 60,000 | 68,500 | 73,000 | 78,000 | 80,000 |

| 41 | 40,000 | 60,000 | 69,500 | 73,500 | 78,500 | 80,000 |

| 42 | 40,000 | 60,000 | 70,000 | 74,000 | 79,000 | 80,000 |

| 43 | 40,000 | 60,000 | 70,500 | 75,000 | 80,0005 | 80,000 |

| 44 | 40,000 | 60,000 | 71,500 | 75,500 | 80,000 | 80,000 |

| 45 | 40,000 | 60,000 | 72,000 | 76,000 | 80,000 | 80,000 |

| 46 | 40,000 | 60,000 | 72,500 | 76,500 | 80,000 | 80,000 |

| 47 | 40,000 | 60,000 | 73,500 | 77,500 | 80,000 | 80,000 |

| 48 | 40,000 | 60,000 | 74,000 | 78,000 | 80,000 | 80,000 |

| 49 | 40,000 | 60,000 | 74,500 | 78,500 | 80,000 | 80,000 |

| 50 | 40,000 | 60,000 | 75,500 | 79,000 | 80,000 | 80,000 |

| 51 | 40,000 | 60,000 | 76,000 | 80,0005 | 80,000 | 80,000 |

| 52 | 40,000 | 60,000 | 76,500 | 80,000 | 80,000 | 80,000 |

| 53 | 40,000 | 60,000 | 77,500 | 80,000 | 80,000 | 80,000 |

| 54 | 40,000 | 60,000 | 78,000 | 80,000 | 80,000 | 80,000 |

| 55 | 40,000 | 60,000 | 78,500 | 80,000 | 80,000 | 80,000 |

| 56 | 40,000 | 60,000 | 79,500 | 80,000 | 80,000 | 80,000 |

| 57 | 40,000 | 60,000 | 80,0005 | 80,000 | 80,000 | 80,000 |

- 1 Calculated values reflect FHWA policy of rounding down when distances fall exactly between 6-inch (15 cm) increments.[27]

- 2 Calculated values reflect FHWA policy of rounding down when weights fall exactly between 500 pound increments.[3]

- 3 Tandem axle by definition.[10]

- 4 Distances between 8 feet (2.4 m) to 8 feet 11 inches (2.72 m) may not be rounded down.[27]

- 5 __ Maximum legal weight limit based on number of axles. Increased axle lengths beyond these do not increase maximum legal weight.[10]

- 6 __ Exception to the formula: when the four axles under consideration are two tandem axles spaced at least 36 feet (11 m) apart, a gross weight of 68,000 pounds (31,000 kg) is allowed.[10]

- __ Upper blank areas represent unrealistic configurations.[3]

References

- ^ a b c d e f "Bridge Formula Weights". U.S. Department of Transportation – Federal Highway Administration. http://ops.fhwa.dot.gov/freight/publications/brdg_frm_wghts/index.htm. Retrieved 2008-02-03.

- ^ a b "Chapter 2 – Truck Size and Weight Limits" (PDF). Comprehensive Truck Size and Weight Study – Volume 2: Issues and Background. Federal Highway Administration. http://www.fhwa.dot.gov/reports/tswstudy/Vol2-Chapter2.pdf. Retrieved 2008-05-03.

- ^ a b c d "Bridge Formula Weights Calculator". U.S. Department of Transportation – Federal Highway Administration. http://ops.fhwa.dot.gov/freight/sw/brdgcalc/calc_page.htm. Retrieved 2008-02-03.

- ^ John Woodrooffe. "Federal Bridge Formula: How it influences vehicle dynamic behavior". University of Michigan Transportation Research Institute, Ann Arbor, MI. http://www.mne.psu.edu/ifrtt/ConferenceProceedings/ISHVWD_9_2006/docs/pdfs/session%2011/s11-2%20152.pdf. Retrieved 2009-03-08.

- ^ "2006 Montana Commercial Vehicle Size and Weight and Safety Trucker's Handbook" (PDF). Montana Department of Transportation. http://www.mdt.mt.gov/publications/docs/manuals/truckers_handbook.pdf. Retrieved 2009-03-09.

- ^ "FMCSA's Strategy". Federal Motor Carrier Safety Administration. http://www.fmcsa.dot.gov/about/what-we-do/strategy/strategy.htm. Retrieved 2008-02-03.

- ^ "Federal Size Regulations for Commercial Motor Vehicles" (PDF). Federal Highway Administration. http://ops.fhwa.dot.gov/freight/publications/size_regs_final_rpt/size_regs_final_rpt.pdf. Retrieved 2008-03-27.

- ^ a b "§658.5 Definitions". Federal Motor Carrier Safety Administration. http://www.fmcsa.dot.gov/rules-regulations/administration/fmcsr/fmcsrruletext.asp?rule_toc=778§ion=658.5§ion_toc=2129. Retrieved 2008-03-27.

- ^ a b c d e "§658.17 Weight". Federal Motor Carrier Safety Administration. http://www.fmcsa.dot.gov/rules-regulations/administration/fmcsr/fmcsrruletext.asp?rule_toc=778§ion=658.17§ion_toc=2135. Retrieved 2008-02-03.

- ^ a b c d "Federal Bridge Gross Weight Formula". Rand McNally. Archived from the original on 2003-03-08. http://web.archive.org/web/20030308203728/http://www.randmcnally.com/pdf/tdm/Federal_Bridge.pdf. Retrieved 2009-03-08.

- ^ a b "Bridge load rating, permitting and posting" (PDF). Florida Department of Transportation. http://www2.dot.state.fl.us/proceduraldocuments/procedures/bin/850010035.pdf. Retrieved 2008-03-28.

- ^ a b Dan Gunderson (August 10, 2007). "Heavy trucks strain roads and bridges". Minnesota Public Radio. http://minnesota.publicradio.org/display/web/2007/08/10/bridgetruckweight/. Retrieved 2008-03-28.

- ^ "Highway Accident Report: Collapse of I-35W Highway Bridge". National Transportation Safety Board. http://www.ntsb.gov/publictn/2008/HAR0803.htm. Retrieved 2009-12-31.

- ^ Jerome R. Corsi (August 5, 2007). "NAFTA Superhighway traffic tied to bridge collapse". WorldNetDaily.com. http://www.wnd.com/news/article.asp?ARTICLE_ID=57017. Retrieved 2008-03-31.

- ^ John Merriss (June 2003). "New Research on Pavement Damage Factors". Oregon Department of Transportation. http://www.oregon.gov/ODOT/CS/EA/policy_notes/03_policy_notes/0603_New_Resrch_on_Pavement_Damage.pdf. Retrieved 2008-03-31.

- ^ "CHAPTER 191 Authorization to use bridges due to condition of bridge". Pennsylvania Department of Transportation. http://www.pacode.com/secure/data/067/chapter191/chap191toc.html. Retrieved 2009-03-21.

- ^ Martin Tolchin (April 12, 1987). "Bridge failures". New York Times. http://query.nytimes.com/gst/fullpage.html?res=9B0DE6DA1F3EF931A25757C0A961948260&sec=&spon=&pagewanted=all. Retrieved 2008-03-28.

- ^ "Many clues to collapse". The Daily Herald (The Daily Herald Co., Everett, WA). August 3, 2007. http://www.heraldnet.com/article/20070803/NEWS02/708030384. Retrieved 2009-03-03.

- ^ Keary H. LeBeau, Sara J. Wadia-Fascetti (July/August 2007). "Fault Tree Analysis of Schoharie Creek Bridge Collapse". American Society of Civil Engineers. http://scitation.aip.org/getabs/servlet/GetabsServlet?prog=normal&id=JPCFEV000021000004000320000001&idtype=cvips&gifs=yes. Retrieved 2009-03-08.

- ^ Associated Press (August 15, 2007). "Truck collapses bridge in Grays Harbor County". Fisher Communications. http://www.komotv.com/news/9187062.html. Retrieved 2008-03-31.

- ^ "Commercial Vehicle Size and Weight Program". Federal Highway Administration. http://ops.fhwa.dot.gov/freight/sw/overview/index.htm. Retrieved 2008-03-27.

- ^ Zachary Schurin (March 20, 2007). "Criminal Penalties for Overweight Trucks". State of Connecticut General Assembly. http://www.cga.ct.gov/2007/rpt/2007-R-0214.htm. Retrieved 2009-04-23.

- ^ "316.545 Weight and load unlawful; special fuel and motor fuel tax enforcement; inspection; penalty; review". The Florida Legislature. http://www.leg.state.fl.us/statutes/index.cfm?App_mode=Display_Statute&Search_String=&URL=Ch0316/Sec545.HTM. Retrieved 2009-04-23.

- ^ "Living With The "Bridge"". Clermont County Engineers Office. 2002-01-02. Archived from the original on 2007-10-07. http://web.archive.org/web/20071010175926/http://www.clermontengineer.org/PlanBridgeFormula.htm. Retrieved 2008-03-27.

- ^ a b "Chapter 6 – Bridge" (PDF). Comprehensive Truck Size and Weight Study – Volume 2: Issues and Background. Federal Highway Administration. http://www.fhwa.dot.gov/reports/tswstudy/Vol3-Chapter6.pdf. Retrieved 2009-03-17.

- ^ a b Truck Weight Limits: Issues and Options. National Research Council. 1990. ISBN 9780309049559. http://books.google.com/?id=c2MVl5782ucC&dq=Truck+weight+limits+By+National+Research+Council+(U.S.).+Committee+for+the+Truck+Weight+Study&printsec=frontcover. Retrieved 2009-03-09.

- ^ a b "Questions and Answers about Vehicle Size and Weight". Federal Highway Administration. Archived from the original on 2008-03-15. http://web.archive.org/web/20080315090620/http://vsw.fhwa.dot.gov/qa/qa.jsp?category=23+CFR+658.17. Retrieved 2008-03-27.

This article incorporates public domain material from the United States Government document "§658.17 Weight, Federal Motor Carrier Safety Administration".