Centrifuge

A centrifuge is a piece of equipment, generally driven by an electric motor (some older models were spun by hand), that puts an object in rotation around a fixed axis, applying a force perpendicular to the axis. The centrifuge works using the sedimentation principle, where the centripetal acceleration causes more dense substances to separate out along the radial direction (the bottom of the tube). By the same token, lighter objects will tend to move to the top (of the tube; in the rotating picture, move to the centre).

In the picture shown, the rotating unit, called the rotor, has fixed holes drilled at an angle (to the vertical). Test tubes are placed in these slots and the motor is spun. As the centripetal force is in the horizontal plane and the tubes are fixed at an angle, the particles have to travel only a little distance before they hit the wall and drop down to the bottom. These angle rotors are very popular in the lab for routine use.

Contents |

Theory

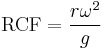

Protocols for centrifugation typically specify the amount of acceleration to be applied to the sample, rather than specifying a rotational speed such as revolutions per minute. This distinction is important because two rotors with different diameters running at the same rotational speed will subject samples to different accelerations. During circular motion the acceleration is the product of the radius and the square of the angular velocity  , and the acceleration relative to "g" is traditionally named "relative centrifugal force" (RCF). The acceleration is measured in multiples of "g" (or × "g"), the standard acceleration due to gravity at the Earth's surface, a dimensionless quantity given by the expression:

, and the acceleration relative to "g" is traditionally named "relative centrifugal force" (RCF). The acceleration is measured in multiples of "g" (or × "g"), the standard acceleration due to gravity at the Earth's surface, a dimensionless quantity given by the expression:

where

is earth's gravitational acceleration,

is earth's gravitational acceleration, is the rotational radius,

is the rotational radius, is the angular velocity in radians per unit time

is the angular velocity in radians per unit time

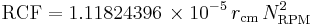

This relationship may be written as

where

is the rotational radius measured in centimetres (cm), and

is the rotational radius measured in centimetres (cm), and is rotational speed measured in revolutions per minute (RPM).

is rotational speed measured in revolutions per minute (RPM).

History and predecessors

English military engineer Benjamin Robins (1707–1751) invented a whirling arm apparatus to determine drag. In 1864, Antonin Prandtl invented the first dairy centrifuge in order to separate cream from milk. In 1879, Gustaf de Laval demonstrated the first continuous centrifugal separator, making its commercial application feasible.

Types

There are at least six types of centrifuge:

- preparative centrifuge

- analytical centrifuge

- angle fixed centrifuge

- swing head centrifuge

- haematocrit centrifuge

- continuous tubular centrifuge

Industrial centrifuges may otherwise be classified according to the type of separation of the high density fraction from the low density one:

- Screen centrifuges, where the centrifugal acceleration allows the liquid to pass through a screen of some sort, through which the solids cannot go (due to granulometry larger than the screen gap or due to agglomeration). Common types are:

- Screen/scroll centrifuges

- Pusher centrifuges

- Peeler centrifuges

- Decanter centrifuges, in which there is no physical separation between the solid and liquid phase, rather an accelerated settling due to centrifugal acceleration.

- Continuous liquid; common types are:

- Solid bowl centrifuges

- Conical plate centrifuges

Uses

Isolating suspensions

Simple centrifuges are used in chemistry, biology, and biochemistry for isolating and separating suspensions. They vary widely in speed and capacity. They usually comprise a rotor containing two, four, six, or many more numbered wells within which the samples, contained in centrifuge tubes, may be placed.

Isotope separation

Other centrifuges, the first being the Zippe-type centrifuge, separate isotopes, and these kinds of centrifuges are in use in nuclear power and nuclear weapon programs.

Gas centrifuges are used in uranium enrichment. The heavier isotope of uranium (uranium-238) in the uranium hexafluoride gas tends to concentrate at the walls of the centrifuge as it spins, while the desired uranium-235 isotope is extracted and concentrated with a scoop selectively placed inside the centrifuge. It takes many thousands of centrifuges to enrich uranium enough for use in a nuclear reactor (around 3.5% enrichment), and many thousands more to enrich it to weapons-grade (above 90% enrichment) for use in nuclear weapons.

Aeronautics and astronautics

Human centrifuges are exceptionally large centrifuges that test the reactions and tolerance of pilots and astronauts to acceleration above those experienced in the Earth's gravity.

The US Air Force at Holloman Air Force Base, New Mexico operates a human centrifuge. The centrifuge at Holloman AFB is operated by the aerospace physiology department for the purpose of training and evaluating prospective fighter pilots for high-g flight in Air Force fighter aircraft.

The use of large centrifuges to simulate a feeling of gravity has been proposed for future long-duration space missions. Exposure to this simulated gravity would prevent or reduce the bone decalcification and muscle atrophy that affect individuals exposed to long periods of freefall. An example of this can be seen in the film 2001: A Space Odyssey.

Geotechnical Centrifuge Modeling

Geotechnical centrifuge modeling is used for physical testing of models involving soils. Centrifuge acceleration is applied to scale models to scale the gravitational acceleration and enable prototype scale stresses to be obtained in scale models. Problems such as building and bridge foundations, earth dams, tunnels, and slope stability, including effects such as blast loading and earthquake shaking.[1] For a discussion of their design, see Geotechnical Centrifuges by Philip Turner.

Commercial applications

- Centrifuges with a batch weight of up to 2,200 kg per charge are used in the sugar industry to separate the sugar crystals from the mother liquor.[2]

- Standalone centrifuges for drying (hand-washed) clothes – usually with a water outlet.

- Centrifuges are used in the attraction Mission: SPACE, located at Epcot in Walt Disney World, which propels riders using a combination of a centrifuge and a motion simulator to simulate the feeling of going into space.

- In soil mechanics, centrifuges utilize centrifugal acceleration to match soil stresses in a scale model to those found in reality.

- Large industrial centrifuges are commonly used in water and wastewater treatment to dry sludges. The resulting dry product is often termed cake, and the water leaving a centrifuge after most of the solids have been removed is called centrate.

- Large industrial centrifuges are also used in the oil industry to remove solids from the drilling fluid.

- Disc-stack centrifuges used by some companies in Oil Sands industry to separate small amounts of water and solids from bitumen

- Centrifuges are used to separate cream (remove fat) from milk.

Separators in dairying

- Separators are centrifuges used on farms or in industrial dairies to separate milk into cream and skimmed milk.

References and notes

- ^ C. W. W. Ng, Y. H. Wang, L. M. Zhang (2006). Physical Modelling in Geotechnics: proceedings of the Sixth International Conference on Physical Modelling in Geotechnics. Taylor & Francis. p. 135. ISBN 0415415861. http://books.google.com/books?id=mzQlFBqJC1wC&pg=RA1-PA186&dq=centrifuge+earthquake#PRA1-PA135,M1.

- ^ article on centrifugal controls, retrieved on June 5, 2010

Further reading

Naesgaard et al., Modeling flow liquefaction, its mitigation, and comparison with centrifuge tests

KEM-TRON Technologies KT-1448 Centrifuge

See also

- Lamm equation

- Sedimentation

- Centrifugal force

- Centrifugation

- Gas centrifuge

- Sedimentation coefficient

- Clearing factor

- Hydroextractor