Thermocouple

A thermocouple is a junction between two different metals that produces a voltage related to a temperature difference. Thermocouples are a widely used type of temperature sensor for measurement and control[1] and can also be used to convert heat into electric power. They are inexpensive[2] and interchangeable, are supplied fitted with standard connectors, and can measure a wide range of temperatures. The main limitation is accuracy: system errors of less than one degree Celsius (C) can be difficult to achieve.[3]

Any junction of dissimilar metals will produce an electric potential related to temperature. Thermocouples for practical measurement of temperature are junctions of specific alloys which have a predictable and repeatable relationship between temperature and voltage. Different alloys are used for different temperature ranges. Properties such as resistance to corrosion may also be important when choosing a type of thermocouple. Where the measurement point is far from the measuring instrument, the intermediate connection can be made by extension wires which are less costly than the materials used to make the sensor. Thermocouples are usually standardized against a reference temperature of 0 degrees Celsius; practical instruments use electronic methods of cold-junction compensation to adjust for varying temperature at the instrument terminals. Electronic instruments can also compensate for the varying characteristics of the thermocouple, and so improve the precision and accuracy of measurements.

Thermocouples are widely used in science and industry; applications include temperature measurement for kilns, gas turbine exhaust, diesel engines, and other industrial processes.

Contents |

Principle of operation

In 1821, the German–Estonian physicist Thomas Johann Seebeck discovered that when any conductor is subjected to a thermal gradient, it will generate a voltage. This is now known as the thermoelectric effect or Seebeck effect. Any attempt to measure this voltage necessarily involves connecting another conductor to the "hot" end. This additional conductor will then also experience the temperature gradient, and develop a voltage of its own which will oppose the original. Fortunately, the magnitude of the effect depends on the metal in use. Using a dissimilar metal to complete the circuit creates a circuit in which the two legs generate different voltages, leaving a small difference in voltage available for measurement. That difference increases with temperature, and is between 1 and 70 microvolts per degree Celsius (µV/°C) for standard metal combinations.

Practical use

Voltage–temperature relationship

| n | Type K |

| 1 | 25.08355 |

| 2 | 7.860106x10−2 |

| 3 | -2.503131x10−1 |

| 4 | 8.315270x10−2 |

| 5 | -1.228034x10−2 |

| 6 | 9.804036x10−4 |

| 7 | -4.413030x10−5 |

| 8 | 1.057734x10−6 |

| 9 | -1.052755x10−8 |

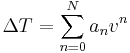

For typical metals used in thermocouples, the output voltage increases almost linearly with the temperature difference (ΔT) over a bounded range of temperatures. For precise measurements or measurements outside of the linear temperature range, non-linearity must be corrected. The nonlinear relationship between the temperature difference (ΔT) and the output voltage (mV) of a thermocouple can be approximated by a polynomial:

The coefficients an are given for n from 0 to between 5 and 13 depending upon the metals. In some cases better accuracy is obtained with additional non-polynomial terms[4]. A database of voltage as a function of temperature, and coefficients for computation of temperature from voltage and vice-versa for many types of thermocouple is available online[4].

In modern equipment the equation is usually implemented in a digital controller or stored in a look-up table;[5] older devices use analog circuits.

Piece-wise linear approximations are an alternative to polynomial corrections[6].

Cold junction compensation

Thermocouples measure the temperature difference between two points, not absolute temperature. To measure a single temperature one of the junctions—normally the cold junction—is maintained at a known reference temperature, and the other junction is at the temperature to be sensed.

Having a junction of known temperature, while useful for laboratory calibration, is not convenient for most measurement and control applications. Instead, they incorporate an artificial cold junction using a thermally sensitive device such as a thermistor or diode to measure the temperature of the input connections at the instrument, with special care being taken to minimize any temperature gradient between terminals. Hence, the voltage from a known cold junction can be simulated, and the appropriate correction applied. This is known as cold junction compensation. Some integrated circuits such as the LT1025 are designed to output a compensated voltage based on thermocouple type and cold junction temperature.

It is worth noting that the EMF (or voltage) is NOT generated at the junction of the two metals of the thermocouple but rather along that portion of the length of the two dissimilar metals that is subjected to a temperature gradient.

Alternatively cold junction compensation can be performed by computation using look-up tables[5] and polynomial interpolation.

Power production

A thermocouple can produce current, which means it can be used to drive some processes directly, without the need for extra circuitry and power sources. For example, the power from a thermocouple can activate a valve when a temperature difference arises. The electrical energy generated by a thermocouple is converted from the heat energy which must be supplied to the hot side to maintain the electric potential. A continuous flow of heat is necessary because the current flowing through the thermocouple tends to cause the hot side to cool down and the cold side to heat up (the Peltier effect).

Thermocouples can be connected in series to form a thermopile, where all the hot junctions are exposed to a higher and all the cold junctions to a lower temperature. The output is the sum of the voltages across the individual junctions, giving larger voltage and power output. Using the radioactive decay of transuranic elements as a heat source, this arrangement has been used to power spacecraft on missions too far from the Sun to utilize solar power.

Grades

Thermocouple wire is available in several different metallurgical formulations per type, typically, in decreasing levels of accuracy and cost: special limits of error, standard, and extension grades.

Extension wire

Extension grade wires made of the same metals as a higher-grade thermocouple are used to connect it to a measuring instrument some distance away without introducing additional junctions between dissimilar materials which would generate unwanted voltages; the connections to the extension wires, being of like metals, do not generate a voltage. In the case of platinum thermocouples, extension wire is a copper alloy, since it would be prohibitively expensive to use platinum for extension wires. The extension wire is specified to have a very similar thermal coefficient of EMF to the thermocouple, but only over a narrow range of temperatures; this reduces the cost significantly.

The temperature-measuring instrument must have high input impedance to prevent any significant current draw from the thermocouple, to prevent a resistive voltage drop across the wire. Changes in metallurgy along the length of the thermocouple (such as termination strips or changes in thermocouple type wire) will introduce another thermocouple junction which affects measurement accuracy.

Types

Certain combinations of alloys have become popular as industry standards. Selection of the combination is driven by cost, availability, convenience, melting point, chemical properties, stability, and output. Different types are best suited for different applications. They are usually selected based on the temperature range and sensitivity needed. Thermocouples with low sensitivities (B, R, and S types) have correspondingly lower resolutions. Other selection criteria include the inertness of the thermocouple material, and whether it is magnetic or not. Standard thermocouple types are listed below with the positive electrode first, followed by the negative electrode.

K

Type K (chromel–alumel) is the most common general purpose thermocouple with a sensitivity of approximately 41 µV/°C, chromel positive relative to alumel.[7] It is inexpensive, and a wide variety of probes are available in its −200 °C to +1350 °C / -328 °F to +2462 °F range. Type K was specified at a time when metallurgy was less advanced than it is today, and consequently characteristics vary considerably between samples. One of the constituent metals, nickel, is magnetic; a characteristic of thermocouples made with magnetic material is that they undergo a step change in output when the magnetic material reaches its Curie point (around 354 °C for type K thermocouples).

E

Type E (chromel–constantan)[5] has a high output (68 µV/°C) which makes it well suited to cryogenic use. Additionally, it is non-magnetic.

J

Type J (iron–constantan) has a more restricted range than type K (−40 to +750 °C), but higher sensitivity of about 55 µV/°C.[2] The Curie point of the iron (770 °C)[8] causes an abrupt change in the characteristic, which determines the upper temperature limit.

N

Type N (Nicrosil–Nisil) (Nickel-Chromium-Silicon/Nickel-Silicon) thermocouples are suitable for use at high temperatures, exceeding 1200 °C, due to their stability and ability to resist high temperature oxidation. Sensitivity is about 39 µV/°C at 900 °C, slightly lower than type K. Designed to be an improved type K, it is becoming more popular.

Platinum types B, R, and S

Types B, R, and S thermocouples use platinum or a platinum–rhodium alloy for each conductor. These are among the most stable thermocouples, but have lower sensitivity than other types, approximately 10 µV/°C. Type B, R, and S thermocouples are usually used only for high temperature measurements due to their high cost and low sensitivity.

- B

Type B thermocouples use a platinum–rhodium alloy for each conductor. One conductor contains 30% rhodium while the other conductor contains 6% rhodium. These thermocouples are suited for use at up to 1800 °C. Type B thermocouples produce the same output at 0 °C and 42 °C, limiting their use below about 50 °C.

- R

Type R thermocouples use a platinum–rhodium alloy containing 13% rhodium for one conductor and pure platinum for the other conductor. Type R thermocouples are used up to 1600 °C.

- S

Type S thermocouples are constructed using one wire of 90% Platinum and 10% Rhodium (the positive or "+" wire) and a second wire of 100% platinum (the negative or "-" wire). Like type R, type S thermocouples are used up to 1600 °C. In particular, type S is used as the standard of calibration for the melting point of gold (1064.43 °C).

T

Type T (copper–constantan) thermocouples are suited for measurements in the −200 to 350 °C range. Often used as a differential measurement since only copper wire touches the probes. Since both conductors are non-magnetic, there is no Curie point and thus no abrupt change in characteristics. Type T thermocouples have a sensitivity of about 43 µV/°C.

C

Type C (tungsten 5% rhenium – tungsten 26% rhenium) thermocouples are suited for measurements in the 0 °C to 2320 °C range. This thermocouple is well-suited for vacuum furnaces at extremely high temperatures. It must never be used in the presence of oxygen at temperatures above 260 °C.

M

Type M thermocouples use a nickel alloy for each wire. The positive wire contains 18% molybdenum while the negative wire contains 0.8% cobalt. These thermocouples are used in vacuum furnaces for the same reasons as with type C. Upper temperature is limited to 1400 °C. It is less commonly used than other types.

Chromel-gold/iron

In chromel-gold/iron thermocouples, the positive wire is chromel and the negative wire is gold with a small fraction (0.03–0.15 atom percent) of iron. It can be used for cryogenic applications (1.2–300 K and even up to 600 K). Both the sensitivity and the temperature range depends on the iron concentration. The sensitivity is typically around 15 µV/K at low temperatures and the lowest usable temperature varies between 1.2 and 4.2 K.

Laws for thermocouples

Law of homogeneous material

A thermoelectric current cannot be sustained in a circuit of a single homogeneous material by the application of heat alone, regardless of how it might vary in cross section. In other words, temperature changes in the wiring between the input and output do not affect the output voltage, provided all wires are made of the same materials as the thermocouple.

Law of intermediate materials

The algebraic sum of the thermoelectric forces in a circuit composed of any number of dissimilar materials is zero if all of the junctions are at a uniform temperature. So If a third metal is inserted in either wire and if the two new junctions are at the same temperature, there will be no net voltage generated by the new metal.

Law of successive or intermediate temperatures

If two dissimilar homogeneous materials produce thermal emf1 when the junctions are at T1 and T2 and produce thermal emf2 when the junctions are at T2 and T3 , the emf generated when the junctions are at T1 and T3 will be emf1 + emf2 .

Aging of thermocouples

Thermoelements are often used at high temperatures and in reactive furnace atmospheres. In this case the practical lifetime is determined by aging. The thermoelectric coefficients of the wires in the area of high temperature change with time and the measurement voltage drops. The simple relationship between the temperature difference of the joints and the measurement voltage is only correct if each wire is homogeneous. With an aged thermocouple this is not the case. Relevant for the generation of the measurement voltage are the properties of the metals at a temperature gradient. If an aged thermocouple is pulled partly out of the furnace, the aged parts from the region previously at high temperature enter the area of temperature gradient and the measurement error is significantly increased. However an aged thermocouple that is pushed deeper into the furnace gives a more accurate reading.

Thermocouple comparison

The table below describes properties of several different thermocouple types. Within the tolerance columns, T represents the temperature of the hot junction, in degrees Celsius. For example, a thermocouple with a tolerance of ±0.0025×T would have a tolerance of ±2.5 °C at 1000 °C.

| Type | Temperature range °C (continuous) | Temperature range °C (short term) | Tolerance class one (°C) | Tolerance class two (°C) | IEC Color code | BS Color code | ANSI Color code |

|---|---|---|---|---|---|---|---|

| K | 0 to +1100 | −180 to +1300 | ±1.5 between −40 °C and 375 °C ±0.004×T between 375 °C and 1000 °C |

±2.5 between −40 °C and 333 °C ±0.0075×T between 333 °C and 1200 °C |

|

|

|

| J | 0 to +700 | −180 to +800 | ±1.5 between −40 °C and 375 °C ±0.004×T between 375 °C and 750 °C |

±2.5 between −40 °C and 333 °C ±0.0075×T between 333 °C and 750 °C |

|

|

|

| N | 0 to +1100 | −270 to +1300 | ±1.5 between −40 °C and 375 °C ±0.004×T between 375 °C and 1000 °C |

±2.5 between −40 °C and 333 °C ±0.0075×T between 333 °C and 1200 °C |

|

|

|

| R | 0 to +1600 | −50 to +1700 | ±1.0 between 0 °C and 1100 °C ±[1 + 0.003×(T − 1100)] between 1100 °C and 1600 °C |

±1.5 between 0 °C and 600 °C ±0.0025×T between 600 °C and 1600 °C |

|

|

Not defined. |

| S | 0 to 1600 | −50 to +1750 | ±1.0 between 0 °C and 1100 °C ±[1 + 0.003×(T − 1100)] between 1100 °C and 1600 °C |

±1.5 between 0 °C and 600 °C ±0.0025×T between 600 °C and 1600 °C |

|

Not defined. | |

| B | +200 to +1700 | 0 to +1820 | Not Available | ±0.0025×T between 600 °C and 1700 °C | No standard use copper wire | No standard use copper wire | Not defined. |

| T | −185 to +300 | −250 to +400 | ±0.5 between −40 °C and 125 °C ±0.004×T between 125 °C and 350 °C |

±1.0 between −40 °C and 133 °C ±0.0075×T between 133 °C and 350 °C |

|

|

|

| E | 0 to +800 | −40 to +900 | ±1.5 between −40 °C and 375 °C ±0.004×T between 375 °C and 800 °C |

±2.5 between −40 °C and 333 °C ±0.0075×T between 333 °C and 900 °C |

|

|

|

| Chromel/AuFe | −272 to +300 | n/a | Reproducibility 0.2% of the voltage; each sensor needs individual calibration. | ||||

Applications

Thermocouples are suitable for measuring over a large temperature range, up to 2300 °C. They are less suitable for applications where smaller temperature differences need to be measured with high accuracy, for example the range 0–100 °C with 0.1 °C accuracy. For such applications thermistors and resistance temperature detectors are more suitable. Applications include temperature measurement for kilns, gas turbine exhaust, diesel engines, and other industrial processes.

Steel industry

Type B, S, R and K thermocouples are used extensively in the steel and iron industries to monitor temperatures and chemistry throughout the steel making process. Disposable, immersible, type S thermocouples are regularly used in the electric arc furnace process to accurately measure the temperature of steel before tapping. The cooling curve of a small steel sample can be analyzed and used to estimate the carbon content of molten steel.

Heating appliance safety

Many gas-fed heating appliances such as ovens and water heaters make use of a pilot flame to ignite the main gas burner when required. If it goes out gas may be released, which is a fire risk and a health hazard. To prevent this some appliances use a thermocouple in a fail-safe circuit to sense when the pilot light is burning. The tip of the thermocouple is placed in the pilot flame, generating a voltage which operates the supply valve which feeds gas to the pilot. So long as the pilot flame remains lit, the thermocouple remains hot, and the pilot gas valve is held open. If the pilot light goes out, the thermocouple temperature falls, causing the voltage across the thermocouple to drop and the valve to close.

Some systems, known as millivolt control systems, extend this concept to the main gas valve as well. Not only does the voltage created by the pilot thermocouple activate the pilot gas valve, it is also routed through a thermostat to power the main gas valve as well. Here, a larger voltage is needed than in a pilot flame safety system described above, and a thermopile is used rather than a single thermocouple. Such a system requires no external source of electricity for its operation and so can operate during a power failure, provided all the related system components allow for this. Note that this excludes common forced air furnaces because external power is required to operate the blower motor, but this feature is especially useful for un-powered convection heaters.

A similar gas shut-off safety mechanism using a thermocouple is sometimes employed to ensure that the main burner ignites within a certain time period, shutting off the main burner gas supply valve should that not happen.

Out of concern for energy wasted by the standing pilot, designers of many newer appliances have switched to an electronically controlled pilot-less ignition, also called intermittent ignition. With no standing pilot flame, there is no risk of gas buildup should the flame go out, so these appliances do not need thermocouple-based safety pilot safety switches. As these designs lose the benefit of operation without a continuous source of electricity, standing pilots are still used in some appliances. The exception is later model instantaneous water heaters that utilise the flow of water to generate the current required to ignite the gas burner, in conjunction with a thermocouple as a safety cut-off device in the event the gas fails to ignite, or the flame is extinguished.

Thermopile radiation sensors

Thermopiles are used for measuring the intensity of incident radiation, typically visible or infrared light, which heats the hot junctions, while the cold junctions are on a heat sink. It is possible to measure radiative intensities of only a few μW/cm2 with commercially available thermopile sensors. For example, some laser power meters are based on such sensors.

Manufacturing

Thermocouples can generally be used in the testing of prototype electrical and mechanical apparatus. For example, switchgear under test for its current carrying capacity may have thermocouples installed and monitored during a heat run test, to confirm that the temperature rise at rated current does not exceed designed limits.

Radioisotope thermoelectric generators

Thermopiles can also be applied to generate electricity in radioisotope thermoelectric generators.

Process plants

Chemical production and petroleum refineries will usually employ computers for logging and limit testing the many temperatures associated with a process, typically numbering in the hundreds. For such cases a number of thermocouple leads will be brought to a common reference block (a large block of copper) containing the second thermocouple of each circuit. The temperature of the block is in turn measured by a thermistor. Simple computations are used to determine the temperature at each measured location.

See also

- Bolometer

- Giuseppe Domenico Botto

- Resistance thermometer

- Thermistor

- List of sensors

- International Temperature Scale of 1990

References

- ↑ "Thermocouple temperature sensors". Temperatures.com. http://www.temperatures.com/tcs.html. Retrieved 2007-11-04.

- ↑ 2.0 2.1 Ramsden, Ed (September 1, 2000). "Temperature measurement". Sensors. http://www.sensorsmag.com/sensors/temperature/temperature-measurement-1030. Retrieved 2010-02-19.

- ↑ "Technical Notes: Thermocouple Accuracy". IEC 584-2(1982)+A1(1989). http://www.microlink.co.uk/tctable.html. Retrieved 2010-04-28.

- ↑ 4.0 4.1 4.2 "NIST ITS-90 Thermocouple Database". http://srdata.nist.gov/its90/main/.

- ↑ 5.0 5.1 5.2 Baker, Bonnie C. (September 1, 2000). "Designing the embedded temperature circuit to meet the system's requirements". Sensors. http://www.sensorsmag.com/sensors/temperature/designing-embedded-temperature-circuit-meet-system039s-requi-1089?print=1. Retrieved 2010-04-26.

- ↑ "Thermocouple Calibration, Microstar Laboratories"

- ↑ Manual on the Use of Thermocouples in Temperature Measurements. ASTM, 1974

- ↑ Buschow, K. H. J.Encyclopedia of materials : science and technology, Elsevier, 2001 ISBN 0-08-043152-6 page 5021 table 1