Calcium oxide

| Calcium oxide | |

|---|---|

|

|

|

Calcium oxide

|

|

|

Other names

Quicklime

|

|

| Identifiers | |

| CAS number | 1305-78-8 |

| PubChem | 14778 |

| UN number | 1910 |

| RTECS number | EW3100000 |

| ATCvet code | QP53 |

| Properties | |

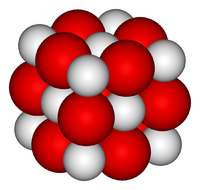

| Molecular formula | CaO |

| Molar mass | 56.077 g/mol |

| Appearance | White to pale yellow powder |

| Density | 3.35 g/cm3 |

| Melting point |

2572 °C (2845 K) |

| Boiling point |

2850 °C (3123 K) |

| Solubility in water | reacts |

| Solubility in [[acids, glycerol, sugar solution]] | soluble |

| Solubility in [[methanol, diethyl ether, n-octanol]] | insoluble |

| Acidity (pKa) | 12.5 |

| Hazards | |

| MSDS | [1] |

| EU Index | Not listed |

| NFPA 704 |

0

3

2

|

| Flash point | Non-flammable |

| Related compounds | |

| Other anions | Calcium sulfide Calcium hydroxide |

| Other cations | Beryllium oxide Magnesium oxide Strontium oxide Barium oxide |

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C, 100 kPa) | |

| Infobox references | |

Calcium oxide (CaO), commonly known as quicklime, is a widely used chemical compound. It is a white, caustic and alkaline crystalline solid at room temperature.

The broadly used term lime connotes calcium-containing inorganic materials, in which carbonates, oxides and hydroxides of calcium, silicon, magnesium, aluminum, & iron predominate, such as limestone. By contrast, quicklime specifically applies to a single chemical compound.

Calcium oxide is usually made by the thermal decomposition of materials such as limestone, that contain calcium carbonate (CaCO3; mineral calcite) in a lime kiln. This is accomplished by heating the material to above 825 °C,[1] a process called calcination or lime-burning, to liberate a molecule of carbon dioxide (CO2); leaving quicklime. The quicklime is not stable and, when cooled, will spontaneously react with CO2 from the air until, after enough time, it is completely converted back to calcium carbonate.

Contents |

Usage

As hydrated or slaked lime, Ca(OH)2 (chemical name calcium hydroxide) (mineral portlandite), it is used in mortar and plaster. Hydrated lime is very simple to make as lime is a basic anhydride and reacts vigorously with water. Lime is also used in glass production and its ability to react with silicates is also used in modern metal production industries (steel in particular) to remove impurities as slag.

It is also used in water and sewage treatment to reduce acidity, to harden, as a flocculant, and to remove phosphates and other impurities; in paper making to dissolve lignin, as a coagulant, and in bleaching; in agriculture to improve acidic soils; and in pollution control, in gas scrubbers to desulfurize waste gases and to treat many liquid effluents. It has traditionally been used in the burial of bodies in open graves, to hide the smell of decomposition, as well as in forensic science, to reveal fingerprints. It is a refractory and a dehydrating agent and is used to purify citric acid, glucose, dyes and as a CO2 absorber. It is also used in pottery, paints and the food industry. Furthermore, quicklime is used in epidemics, plagues, and disasters to disintegrate bodies to help fight the spread of disease. Quicklime is a key ingredient in the nixtamalization process used to create corn hominy and masa or tortilla dough. In ancient India, before the discovery of soap, it was mixed with sand and used to clean one's body; it was also used to build houses.

A relatively inexpensive substance, quicklime produces heat energy by the formation of the hydrate, calcium hydroxide, as in the following equation:[2]

- CaO (s) + H2O (l)

Ca(OH)2 (aq) (ΔHr = −63.7 kJ/mol of CaO)

Ca(OH)2 (aq) (ΔHr = −63.7 kJ/mol of CaO)

The hydrate can be reconverted to quicklime by removing the water in the reversible equation. If the hydrated lime is heated to redness, the quicklime will be regenerated to reverse the reaction. As it hydrates, an exothermic reaction results. One liter of water combines with approximately 3.1 kg of quicklime to give calcium hydroxide plus 3.54 MJ of energy. This process can be used to provide a convenient portable source of heat, as for on-the-spot food warming in a self-heating can.

When quicklime is heated to 2400 °C (4300 °F), it emits an intense glow. This form of illumination is known as a limelight, and was used broadly in theatrical productions prior to the invention of electric lighting.[3]

Annual worldwide production of quicklime is around 283 million metric tons. China is by far the world's largest producer, with a total of around 170 million metric tons per year. The United States is the next largest with around 20 million metric tons per year.[4]

Use as a weapon

Historian and philosopher David Hume, in his history of England, recounts that early in the reign of Henry III, the English Navy destroyed an invading French fleet by blinding the enemy fleet with quicklime:

D’Albiney employed a stratagem against them, which is said to have contributed to the victory: Having gained the wind of the French, he came down upon them with violence; and throwing in their faces a great quantity of quicklime, which he purposely carried on board, he so blinded them, that they were disabled from defending themselves.[5]

Quicklime is also thought to have been a component of Greek fire. Upon contact with water, quicklime would increase its temperature above 150 °C and ignite the fuel.[6]

Health issues

Because of vigorous reaction of quicklime with water, quicklime causes severe irritation when inhaled or placed in contact with moist skin or eyes. Inhalation may cause coughing, sneezing, labored breathing. It may then evolve into burns with perforation of the nasal septum, abdominal pain, nausea and vomiting. Although quicklime is not considered a fire hazard, its reaction with water can release enough heat to ignite combustible materials.[7]

References

- ↑ Merck Index of chemicals and Drugs , 9th edition monograph 1650

- ↑ U.S. Patent 3,955,554, Solar heating system.

- ↑ Gray, Theodore (September 2007). "Limelight in the Limelight". Popular Science: 84. http://www.popsci.com/node/9652.

- ↑ Miller, M. Michael (2007). "Lime". Minerals Yearbook. U.S. Geological Survey. p. 43.13. http://minerals.usgs.gov/minerals/pubs/commodity/lime/myb1-2007-lime.pdf.

- ↑ David Hume (1688). History of England. I. http://www.gutenberg.org/files/19212/19212-h/19212-h.htm#2H_4_0002.

- ↑ Croddy, Eric (2002). Chemical and biological warfare: a comprehensive survey for the concerned citizen. Springer. p. 128. ISBN 0387950761. http://books.google.com/?id=MQMGhInCvlgC&pg=PA128.

- ↑ CaO MSDS

External links

- A discussion of lime and its uses (US context) by the US Geological Survey

- Factors Affecting the Quality of Quicklime

- American Scientist (discussion of 14C dating of mortar)

- Chemical of the Week - Lime

- Lime production process presentation

- Material Safety Data Sheet

|

|||||