Ethanol fuel

| Renewable energy |

|---|

|

Biofuel |

Ethanol fuel is ethanol (ethyl alcohol), the same type of alcohol found in alcoholic beverages. It is most often used as a motor fuel, mainly as a biofuel additive for gasoline. World ethanol production for transport fuel tripled between 2000 and 2007 from 17 billion to more than 52 billion litres. From 2007 to 2008, the share of ethanol in global gasoline type fuel use increased from 3.7% to 5.4%.[1] In 2009 worldwide ethanol fuel production reached 19.5 billion gallons (73.9 billion liters).[2]

Ethanol is widely used in Brazil and in the United States, and together both countries were responsible for 89 percent of the world's ethanol fuel production in 2009.[2] Most cars on the road today in the U.S. can run on blends of up to 10% ethanol,[3] and the use of 10% ethanol gasoline is mandated in some U.S. states and cities. Since 1976 the Brazilian government has made it mandatory to blend ethanol with gasoline, and since 2007 the legal blend is around 25% ethanol and 75% gasoline (E25).[4] In addition, by 2010 Brazil had a fleet of more than 10 million flexible-fuel vehicles regularly using neat ethanol fuel (known as E100).[5][6]

Bioethanol, unlike petroleum, is a form of renewable energy that can be produced from agricultural feedstocks. It can be made from very common crops such as sugar cane, potato, manioc and maize. However, there has been considerable debate about how useful bioethanol will be in replacing gasoline. Concerns about its production and use relate to increased food prices, the large amount of arable land required for crops,[7] as well as the energy and pollution balance of the whole cycle of ethanol production, especially from corn.[8][9] Recent developments with cellulosic ethanol production and commercialization may allay some of these concerns.[10]

Cellulosic ethanol offers promise because cellulose fibers, a major and universal component in plant cells walls, can be used to produce ethanol.[11][12] According to the International Energy Agency, cellulosic ethanol could allow ethanol fuels to play a much bigger role in the future than previously thought.[13]

Contents |

Chemistry

Glucose (a simple sugar) is created in the plant by photosynthesis.

- 6 CO2 + 6 H2O + light → C6H12O6 + 6 O2

During ethanol fermentation, glucose is decomposed into ethanol and carbon dioxide.

- C6H12O6 → 2 C2H5OH+ 2 CO2 + heat

During combustion ethanol reacts with oxygen to produce carbon dioxide, water, and heat:

- C2H5OH + 3 O2 → 2 CO2 + 3 H2O + heat

After doubling the combustion reaction because two molecules of ethanol are produced for each glucose molecule, and adding all three reactions together, there are equal numbers of each type of molecule on each side of the equation, and the net reaction for the overall production and consumption of ethanol is just:

- light → heat

The heat of the combustion of ethanol is used to drive the piston in the engine by expanding heated gases. It can be said that sunlight is used to run the engine.

Glucose itself is not the only substance in the plant that is fermented. The simple sugar fructose also undergoes fermentation. Three other compounds in the plant can be fermented after breaking them up by hydrolysis into the glucose or fructose molecules that compose them. Starch and cellulose are molecules that are strings of glucose molecules, and sucrose (ordinary table sugar) is a molecule of glucose bonded to a molecule of fructose. The energy to create fructose in the plant ultimately comes from the metabolism of glucose created by photosynthesis, and so sunlight also provides the energy generated by the fermentation of these other molecules.

Ethanol may also be produced industrially from ethene (ethylene). Addition of water to the double bond converts ethene to ethanol:

- C2H4 + H2O → CH3CH2OH

This is done in the presence of an acid which catalyzes the reaction, but is not consumed. The ethene is produced from petroleum by steam cracking.

When ethanol is burned in the atmosphere rather than in pure oxygen, other chemical reactions occur with different components of the atmosphere such as N2. This leads to the production of nitrous oxides NOx , a major air pollutant.

Sources

Ethanol is a renewable energy source because the energy is generated by using a resource, sunlight, which is naturally replenished. Creation of ethanol starts with photosynthesis causing a feedstock, such as sugar cane or corn, to grow. These feedstocks are processed into ethanol.

About 5% of the ethanol produced in the world in 2003 was actually a petroleum product.[14] It is made by the catalytic hydration of ethylene with sulfuric acid as the catalyst. It can also be obtained via ethylene or acetylene, from calcium carbide, coal, oil gas, and other sources. Two million tons of petroleum-derived ethanol are produced annually. The principal suppliers are plants in the United States, Europe, and South Africa.[15] Petroleum derived ethanol (synthetic ethanol) is chemically identical to bio-ethanol and can be differentiated only by radiocarbon dating.[16]

Bio-ethanol is usually obtained from the conversion of carbon based feedstock. Agricultural feedstocks are considered renewable because they get energy from the sun using photosynthesis, provided that all minerals required for growth (such as nitrogen and phosphorus) are returned to the land. Ethanol can be produced from a variety of feedstocks such as sugar cane, bagasse, miscanthus, sugar beet, sorghum, grain sorghum, switchgrass, barley, hemp, kenaf, potatoes, sweet potatoes, cassava, sunflower, fruit, molasses, corn, stover, grain, wheat, straw, cotton, other biomass, as well as many types of cellulose waste and harvestings, whichever has the best well-to-wheel assessment.

An alternative process to produce bio-ethanol from algae is being developed by the company Algenol. Rather than grow din mor algae and then harvest and ferment it the algae grow in sunlight and produce ethanol directly which is removed without killing the algae. It is claimed the process can produce 6000 gallons per acre per year compared with 400 gallons for corn production.[17]

Currently, the first generation processes for the production of ethanol from corn use only a small part of the corn plant: the corn kernels are taken from the corn plant and only the starch, which represents about 50% of the dry kernel mass, is transformed into ethanol. Two types of second generation processes are under development. The first type uses enzymes and yeast to convert the plant cellulose into ethanol while the second type uses pyrolysis to convert the whole plant to either a liquid bio-oil or a syngas. Second generation processes can also be used with plants such as grasses, wood or agricultural waste material such as straw.

Production process

The basic steps for large scale production of ethanol are: microbial (yeast) fermentation of sugars, distillation, dehydration (requirements vary, see Ethanol fuel mixtures, below), and denaturing (optional). Prior to fermentation, some crops require saccharification or hydrolysis of carbohydrates such as cellulose and starch into sugars. Saccharification of cellulose is called cellulolysis (see cellulosic ethanol). Enzymes are used to convert starch into sugar.[18]

Fermentation

Ethanol is produced by microbial fermentation of the sugar. Microbial fermentation will currently only work directly with sugars. Two major components of plants, starch and cellulose, are both made up of sugars, and can in principle be converted to sugars for fermentation. Currently, only the sugar (e.g. sugar cane) and starch (e.g. corn) portions can be economically converted. However, there is much activity in the area of cellulosic ethanol, where the cellulose part of a plant is broken down to sugars and subsequently converted to ethanol.

Distillation

For the ethanol to be usable as a fuel, water must be removed. Most of the water is removed by distillation, but the purity is limited to 95-96% due to the formation of a low-boiling water-ethanol azeotrope. The 95.6% m/m (96.5% v/v) ethanol, 4.4% m/m (3.5% v/v) water mixture may be used as a fuel alone, but unlike anhydrous ethanol, is immiscible in gasoline, so the water fraction is typically removed in further treatment in order to burn in combination with gasoline in gasoline engines.

Dehydration

There are basically five dehydration processes to remove the water from an azeotropic ethanol/water mixture. The first process, used in many early fuel ethanol plants, is called azeotropic distillation and consists of adding benzene or cyclohexane to the mixture. When these components are added to the mixture, it forms a heterogeneous azeotropic mixture in vapor-liquid-liquid equilibrium, which when distilled produces anhydrous ethanol in the column bottom, and a vapor mixture of water and cyclohexane/benzene. When condensed, this becomes a two-phase liquid mixture. Another early method, called extractive distillation, consists of adding a ternary component which will increase ethanol's relative volatility. When the ternary mixture is distilled, it will produce anhydrous ethanol on the top stream of the column.

With increasing attention being paid to saving energy, many methods have been proposed that avoid distillation all together for dehydration. Of these methods, a third method has emerged and has been adopted by the majority of modern ethanol plants. This new process uses molecular sieves to remove water from fuel ethanol. In this process, ethanol vapor under pressure passes through a bed of molecular sieve beads. The bead's pores are sized to allow absorption of water while excluding ethanol. After a period of time, the bed is regenerated under vacuum or in the flow of inert atmosphere (e.g. N2)to remove the absorbed water. Two beds are used so that one is available to absorb water while the other is being regenerated. This dehydration technology can account for energy saving of 3,000 btus/gallon (840 kJ/l) compared to earlier azeotropic distillation.[19]

Technology

Ethanol-based engines

Ethanol is most commonly used to power automobiles, though it may be used to power other vehicles, such as farm tractors, boats and airplanes. Ethanol (E100) consumption in an engine is approximately 51% higher than for gasoline since the energy per unit volume of ethanol is 34% lower than for gasoline.[20][21] However, the higher compression ratios in an ethanol-only engine allow for increased power output and better fuel economy than could be obtained with lower compression ratios.[22][23] In general, ethanol-only engines are tuned to give slightly better power and torque output than gasoline-powered engines. In flexible fuel vehicles, the lower compression ratio requires tunings that give the same output when using either gasoline or hydrated ethanol. For maximum use of ethanol's benefits, a much higher compression ratio should be used,[24] Current high compression neat ethanol engine designs are approximately 20-30% less fuel efficient than their gasoline-only counterparts.[25]

A 2004 MIT study[26] and an earlier paper published by the Society of Automotive Engineers[27] identify a method to exploit the characteristics of fuel ethanol substantially better than mixing it with gasoline. The method presents the possibility of leveraging the use of alcohol to achieve definite improvement over the cost-effectiveness of hybrid electric. The improvement consists of using dual-fuel direct-injection of pure alcohol (or the azeotrope or E85) and gasoline, in any ratio up to 100% of either, in a turbocharged, high compression-ratio, small-displacement engine having performance similar to an engine having twice the displacement. Each fuel is carried separately, with a much smaller tank for alcohol. The high-compression (which increases efficiency) engine will run on ordinary gasoline under low-power cruise conditions. Alcohol is directly injected into the cylinders (and the gasoline injection simultaneously reduced) only when necessary to suppress ‘knock’ such as when significantly accelerating. Direct cylinder injection raises the already high octane rating of ethanol up to an effective 130. The calculated over-all reduction of gasoline use and CO2 emission is 30%. The consumer cost payback time shows a 4:1 improvement over turbo-diesel and a 5:1 improvement over hybrid. In addition, the problems of water absorption into pre-mixed gasoline (causing phase separation), supply issues of multiple mix ratios and cold-weather starting are avoided.

Ethanol's higher octane rating allows an increase of an engine's compression ratio for increased thermal efficiency.[22] In one study, complex engine controls and increased exhaust gas recirculation allowed a compression ratio of 19.5 with fuels ranging from neat ethanol to E50. Thermal efficiency up to approximately that for a diesel was achieved.[28] This would result in the fuel economy of a neat ethanol vehicle to be about the same as one burning gasoline.

Since 1989 there have also been ethanol engines based on the diesel principle operating in Sweden.[29] They are used primarily in city buses, but also in distribution trucks and waste collectors. The engines, made by Scania, have a modified compression ratio, and the fuel (known as ED95) used is a mix of 93.6 % ethanol and 3.6 % ignition improver, and 2.8% denaturants.[30] The ignition improver makes it possible for the fuel to ignite in the diesel combustion cycle. It is then also possible to use the energy efficiency of the diesel principle with ethanol. These engines have been used in the United Kingdom by Reading Transport but the use of bioethanol fuel is now being phased out.

Engine cold start during the winter

High ethanol blends present a problem to achieve enough vapor pressure for the fuel to evaporate and spark the ignition during cold weather (since ethanol tends to increase fuel enthalpy of vaporization[31]). When vapor pressure is below 45 kPa starting a cold engine becomes difficult.[32] In order to avoid this problem at temperatures below 11 ° Celsius (59 °F), and to reduce ethanol higher emissions during cold weather, both the US and the European markets adopted E85 as the maximum blend to be used in their flexible fuel vehicles, and they are optimized to run at such a blend. At places with harsh cold weather, the ethanol blend in the US has a seasonal reduction to E70 for these very cold regions, though it is still sold as E85.[33][34] At places where temperatures fall below -12 °C (10 °F) during the winter, it is recommended to install an engine heater system, both for gasoline and E85 vehicles. Sweden has a similar seasonal reduction, but the ethanol content in the blend is reduced to E75 during the winter months.[34][35]

Brazilian flex fuel vehicles can operate with ethanol mixtures up to E100, which is hydrous ethanol (with up to 4% water), which causes vapor pressure to drop faster as compared to E85 vehicles. As a result, Brazilian flex vehicles are built with a small secondary gasoline reservoir located near the engine. During a cold start pure gasoline is injected to avoid starting problems at low temperatures. This provision is particularly necessary for users of Brazil's southern and central regions, where temperatures normally drop below 15 ° Celsius (59 °F) during the winter. An improved flex engine generation was launched in 2009 that eliminates the need for the secondary gas storage tank.[36][37] In March 2009 Volkswagen do Brasil launched the Polo E-Flex, the first Brazilian flex fuel model without an auxiliary tank for cold start.[38][39]

Ethanol fuel mixtures

To avoid engine stall due to "slugs" of water in the fuel lines interrupting fuel flow, the fuel must exist as a single phase. The fraction of water that an ethanol-gasoline fuel can contain without phase separation increases with the percentage of ethanol.[40]. This shows, for example, that E30 can have up to about 2% water. If there is more than about 71% ethanol, the remainder can be any proportion of water or gasoline and phase separation will not occur. However, the fuel mileage declines with increased water content. The increased solubility of water with higher ethanol content permits E30 and hydrated ethanol to be put in the same tank since any combination of them always results in a single phase. Somewhat less water is tolerated at lower temperatures. For E10 it is about 0.5% v/v at 70 F and decreases to about 0.23% v/v at -30 F.[41]

In many countries cars are mandated to run on mixtures of ethanol. Brazil requires cars be suitable for a 25% ethanol blend, and has required various mixtures between 22% and 25% ethanol, since of July 2007 25% is required. The United States allows up to 10% blends, and some states require this (or a smaller amount) in all gasoline sold. Other countries have adopted their own requirements. Beginning with the model year 1999, an increasing number of vehicles in the world are manufactured with engines which can run on any fuel from 0% ethanol up to 100% ethanol without modification. Many cars and light trucks (a class containing minivans, SUVs and pickup trucks) are designed to be flexible-fuel vehicles (also called dual-fuel vehicles). In older model years, their engine systems contained alcohol sensors in the fuel and/or oxygen sensors in the exhaust that provide input to the engine control computer to adjust the fuel injection to achieve stochiometric (no residual fuel or free oxygen in the exhaust) air-to-fuel ratio for any fuel mix. In newer models, the alcohol sensors have been removed, with the computer using only oxygen and airflow sensor feedback to estimate alcohol content. The engine control computer can also adjust (advance) the ignition timing to achieve a higher output without pre-ignition when it predicts that higher alcohol percentages are present in the fuel being burned. This method is backed up by advanced knock sensors - used in most high performance gasoline engines regardless of whether they're designed to use ethanol or not - that detect pre-ignition and detonation.

Fuel economy

In theory, all fuel-driven vehicles have a fuel economy (measured as miles per US gallon, or liters per 100 km) that is directly proportional to the fuel's energy content.[42] In reality, there are many other variables that come in to play that affect the performance of a particular fuel in a particular engine. Ethanol contains approx. 34% less energy per unit volume than gasoline, and therefore in theory, burning pure ethanol in a vehicle will result in a 34% reduction in miles per US gallon , given the same fuel economy, compared to burning pure gasoline. Since ethanol has a higher octane rating, the engine can be made more efficient by raising its compression ratio. In fact using a variable turbocharger, the compression ratio can be optimized for the fuel being used, making fuel economy almost constant for any blend. .[20][21] For E10 (10% ethanol and 90% gasoline), the effect is small (~3%) when compared to conventional gasoline,[43] and even smaller (1-2%) when compared to oxygenated and reformulated blends.[44] However, for E85 (85% ethanol), the effect becomes significant. E85 will produce lower mileage than gasoline, and will require more frequent refueling. Actual performance may vary depending on the vehicle. Based on EPA tests for all 2006 E85 models, the average fuel economy for E85 vehicles resulted 25.56% lower than unleaded gasoline.[45] The EPA-rated mileage of current USA flex-fuel vehicles[46] should be considered when making price comparisons, but it must be noted that E85 is a high performance fuel, with an octane rating of about 104, and should be compared to premium. In one estimate[47] the US retail price for E85 ethanol is 2.62 US dollar per gallon or 3.71 dollar corrected for energy equivalency compared to a gallon of gasoline priced at 3.03 dollar. Brazilian cane ethanol (100%) is priced at 3.88 dollar against 4.91 dollar for E25 (as July 2007).

Consumer production systems

While biodiesel production systems have been marketed to home and business users for many years, commercialized ethanol production systems designed for end-consumer use have lagged in the marketplace. In 2008, two different companies announced home-scale ethanol production systems. The AFS125 Advanced Fuel System[48] from Allard Research and Development is capable of producing both ethanol and biodiesel in one machine, while the E-100 MicroFueler[49] from E-Fuel Corporation is dedicated to ethanol only.

Experience by country

The world's top ethanol fuel producers in 2009 were the United States with 10.75 billion U.S. liquid gallons (bg) and Brazil (6.58 bg), accounting for 89% of world production of 19.53 billion US gallons (73.9 billion liters or 58.3 million metric tonnes).[2] Strong incentives, coupled with other industry development initiatives, are giving rise to fledgling ethanol industries in countries such as Germany, Spain, France, Sweden, China, Thailand, Canada, Colombia, India, Australia, and some Central American countries.

| Annual Fuel Ethanol Production by Country (2007–2009)[2][50] Top 10 countries/regional blocks (Millions of U.S. liquid gallons per year) |

||||

|---|---|---|---|---|

| World rank |

Country/Region | 2009 | 2008 | 2007 |

| 1 | 10,750.00 | 9,000.00 | 6,498.60 | |

| 2 | 6,577.89 | 6,472.20 | 5,019.20 | |

| 3 | 1,039.52 | 733.60 | 570.30 | |

| 4 | 541.55 | 501.90 | 486.00 | |

| 5 | 435.20 | 89.80 | 79.20 | |

| 6 | 290.59 | 237.70 | 211.30 | |

| 7 | 91.67 | 66.00 | 52.80 | |

| 8 | 83.21 | 79.30 | 74.90 | |

| 9 | 56.80 | 26.40 | 26.40 | |

| 10 | Other | 247.27 | ||

| World Total | 19,534.99 | 17,335.29 | 13,101.70 | |

Brazil

Brazil has the largest and most successful bio-fuel programs in the world, involving production of ethanol fuel from sugarcane, and it is considered to have the world's first sustainable biofuels economy.[51][52][53] In 2006 Brazilian ethanol provided 18% of the country's road transport sector fuel consumption needs,[54][55] and by April 2008, more than 50% of fuel consumption for the gasoline market.[52][56][57] As a result of the increasing use of ethanol, together with the exploitation of domestic deep water oil sources, Brazil reached in 2006 a volumetric self-sufficiency in oil supply, but is not effectively self-sufficient, since most of it's locally extracted oil is heavy. [58][59][60]

Together, Brazil and the United States lead the industrial world in global ethanol fuel production, accounting together for 89% of worldwide production.[2] In 2009 Brazil produced 24.9 billion liters (6.57 billion U.S. liquid gallons),[2] representing 33.7% of the world's total ethanol used as fuel. Sugar cane plantations cover 3.6 million hectares of land for ethanol production, representing just 1% of Brazil's arable land, with a productivity of 7,500 liters of ethanol per hectare, as compared with the U.S. maize ethanol productivity of 3,000 liters per hectare.[51][61]

The ethanol industry in Brazil is more than 30 year-old and even though it is no longer subsidized, production and use of ethanol was stimulated through:

-

- Low-interest loans for the construction of ethanol distilleries

- Guaranteed purchase of ethanol by the state-owned oil company at a reasonable price

- Retail pricing of neat ethanol so it is competitive if not slightly favorable to the gasoline-ethanol blend

- Tax incentives provided during the 1980s to stimulate the purchase of neat ethanol vehicles.[62]

Guaranteed purchase and price regulation were ended some years ago, with relatively positive results. In addition to these other policies, ethanol producers in the state of São Paulo established a research and technology transfer center that has been effective in improving sugar cane and ethanol yields.[62]

There are no longer light vehicles in Brazil running on pure gasoline. Since 1977 the government made mandatory to blend 20% of ethanol (E20) with gasoline (gasohol), requiring just a minor adjustment on regular gasoline motors. Today the mandatory blend is allowed to vary nationwide between 20% to 25% ethanol (E25) and it is used by all regular gasoline vehicles and flexible-fuel vehicles. The Brazilian car manufacturing industry developed flexible-fuel vehicles that can run on any proportion of gasoline and ethanol.[63] Introduced in the market in 2003, these vehicles became a commercial success.[64] By December 2009 the fleet of "flex" cars and light commercial vehicles had reached 9.35 million vehicles,[65][66] and 183.3 thousand flex-fuel motorcycles.[67] The cumulative production of flex-fuel cars and light commercial vehicles since 2003 reached the milestone of 10 million units produced in March 2010.[5][6] The ethanol-powered "flex" vehicles, as they are popularly known, are manufactured to tolerate hydrated ethanol (E100), an azeotrope composed of 95.6% ethanol and 4.4% water.[45]

The latest innovation within the Brazilian flexible-fuel technology is the development of flex-fuel motorcycles.[68][69] The first flex motorcycle was launched to the market by Honda in March 2009. Produced by its Brazilian subsidiary Moto Honda da Amazônia, the CG 150 Titan Mix is sold for around US$2,700.[70][71][72] During the first eight months after its market launch the CG 150 Titan Mix has sold 139,059 motorcycles, capturing a 10.6% market share, and ranking second in sales of new motorcycles in the Brazilian market by October 2009.[73]

United States

production and imports (2001–2009)[74] (Millions of U.S. liquid gallons) |

|||

|---|---|---|---|

| Year | Production | Imports | Demand |

| 2001 | 1,770 | n/a | n/a |

| 2002 | 2,130 | 46 | 2,085 |

| 2003 | 2,800 | 61 | 2,900 |

| 2004 | 3,400 | 161 | 3,530 |

| 2005 | 3,904 | 135 | 4,049 |

| 2006 | 4,855 | 653 | 5,377 |

| 2007 | 6,500 | 450 | 6,847 |

| 2008 | 9,000 | 556 | 9,637 |

| 2009 | 10,600 | 190 | 10,940 |

| Note: Demand figures includes stocks change and small exports in 2005 |

|||

The United States produces and consumes more ethanol fuel than any other country in the world. Ethanol use as fuel dates back to Henry Ford, who in 1896 designed his first car, the "Quadricycle" to run on pure ethanol.[45] Then in 1908, he produced the famous Ford Model T capable of running on gasoline, ethanol or a combination of both.[45][75] Ford continued to advocate for ethanol as fuel even during Prohibition.[45]

Most cars on the road today in the U.S. can run on blends of up to 10% ethanol, and motor vehicle manufacturers already produce vehicles designed to run on much higher ethanol blends. In 2007 Portland, Oregon, became the first city in the United States to require all gasoline sold within city limits to contain at least 10% ethanol.[76][77] As of January 2008, three states — Missouri, Minnesota, and Hawaii — require ethanol to be blended with gasoline motor fuel. Many cities also require ethanol blends due to non-attainment of federal air quality goals.[78]

Several motor vehicle manufacturers, including Ford, Chrysler, and GM, sell flexible-fuel vehicles that can use gasoline and ethanol blends ranging from pure gasoline all the way up to 85% ethanol (E85). By December 2009 it was estimated there were 8.4 million E85-compatible vehicles on U.S. roads,[79] though actual used of E85 fuel is limited, not only because the ethanol fueling infrastructures is limited,[80] but also because many owners are not aware their vehicle is flex-fuel capable.[45]

In the USA there are currently about 1,900 stations distributing ethanol, although most stations are in the corn belt area.[81][82] One of the debated methods for distribution in the US is using existing oil pipelines,[83] which raises concerns over corrosion. In any case, some companies proposed building a 1,700-mile pipeline to carry ethanol from the Midwest through Central Pennsylvania to New York.[84]

The production of fuel ethanol from corn in the United States is controversial for a few reasons. Production of ethanol from corn is 5 to 6 times less efficient than producing it from sugarcane. Ethanol production from corn is highly dependent upon subsidies and it consumes a food crop to produce fuel.[47] The subsidies paid to fuel blenders and ethanol refineries have often been cited as the reason for driving up the price of corn, and in farmers planting more corn and the conversion of considerable land to corn (maize) production which generally consumes more fertilizers and pesticides than many other land uses.[47] This is at odds with the subsidies actually paid directly to farmers that are designed to take corn land out of production and pay farmers to plant grass and idle the land, often in conjunction with soil conservation programs, in an attempt to boost corn prices. Recent developments with cellulosic ethanol production and commercialization may allay some of these concerns. A theoretically much more efficient way of ethanol production has been suggested to use sugar beets which make about the same amount of ethanol as corn without using the corn food crop especially since sugar beets can grow in less tropical conditions than sugar cane.[10]

On October 2008 the first "biofuels corridor" was officially opened along I-65, a major interstate highway in the central United States. Stretching from northern Indiana to southern Alabama, this corridor consisting of more than 200 individual fueling stations makes it possible to drive a flex-fueled vehicle from Lake Michigan to the Gulf of Mexico without being further than a quarter tank worth of fuel from an E85 pump.[85][86][87]

On April 23, 2009, the California Air Resources Board approved the specific rules and carbon intensity reference values for the California Low-Carbon Fuel Standard (LCFS) that will go into effect in January 1, 2011.[88][89][90] During the consultation process there was controversy regarding the inclusion and modeling of indirect land use change effects.[91][92][93][94][95] After the CARB's ruling, among other criticisms, representatives of the US ethanol industry complained that this standard overstates the environmental effects of corn ethanol, and also criticized the inclusion of indirect effects of land-use changes as an unfair penalty to domestically produced corn ethanol because deforestation in the developing world is being tied to US ethanol production.[89][96][97][98][99][100][101] The initial reference value set for 2011 for LCFS means that Mid-west corn ethanol will not meet the California standard unless current carbon intensity is reduced.[88][99][101][102]

A similar controversy arose after the U.S. Environmental Protection Agency (EPA) published on May 5, 2009, its notice of proposed rulemaking for the new Renewable Fuel Standard (RFS).[103] The draft of the regulations was released for public comment during a 60-day period. EPA's proposed regulations also included the carbon footprint from indirect land-use changes.[104][105] On the same day, President Barack Obama signed a Presidential Directive with the aim to advance biofuels research and improve their commercialization. The Directive established a Biofuels Interagency Working Group comprising of three agencies, the Department of Agriculture, the Environmental Protection Agency, and the Department of Energy.[106][107] This group will develop a plan to increase flexible fuel vehicle use and assist in retail marketing efforts. Also they will coordinate infrastructure policies impacting the supply, secure transport, and distribution of biofuels. The group will also come up with policy ideas for increasing investment in next-generation fuels, such as cellulosic ethanol, and for reducing the environmental footprint of growing biofuels crops, particularly corn-based ethanol.[106][107][108]

In 2010, an industry lobbist group claims that increasing the percentage of ethanol in gasoline would create 136,000 jobs. The Environmental Working Group says that 27,000 might be created, each costing the taxpayers $446,000 per year (in 2010 constant dollars).[109]

Europe

| Production of Bioethanol in the |

||||

|---|---|---|---|---|

| No | Country | 2005 | 2006 | |

| 1 | 978 | 2,554 | ||

| 2 | 1,796 | 2,382 | ||

| 3 | 853 | 1,482 | ||

| 4 | 907 | 830 | ||

| 5 | 47 | 759 | ||

| 6 | 379 | 711 | ||

| 7 | 207 | 201 | ||

| 8 | 47 | 107 | ||

| 9 | 47 | 89 | ||

| 10 | 0 | 89 | ||

| 11 | 71 | 71 | ||

| 12 | 77 | 0 | ||

| 27 | Total | 5,411 | 9,274 | |

| n.a. = not available | ||||

| Consumption of Bioethanol in the |

||||

|---|---|---|---|---|

| No | Country | 2005 | 2006 | 2007 |

| 1 | 1,682 | 3,544 | 3,408 | |

| 2 | 871 | 1,719 | 3,174 | |

| 3 | 1,681 | 1,894 | 2,113 | |

| 4 | 1,314 | 1,332 | 1,310 | |

| 5 | 329 | 611 | 991 | |

| 6 | 502 | 563 | 907 | |

| 7 | - | 0 | 769 | |

| 8 | 0 | 0 | 254 | |

| 9 | 0 | 4 | 154 | |

| 10 | 10 | 64 | 135 | |

| 11 | 28 | 136 | 107 | |

| 12 | 0 | 179 | 101 | |

| 13 | - | 42 | 70 | |

| 14 | 0 | 13 | 54 | |

| 15 | 5 | 12 | 20 | |

| 16 | 0 | 0 | 10 | |

| 17 | 0 | 2 | 9 | |

| 18 | 0 | 13 | 2 | |

| 19 | 59 | 0 | 0 | |

| 20 | 0 | 10 | n.a. | |

| 27 | EU | 6,481 | 10,138 | 13,563 |

The consumption of bioethanol is largest in Europe in Germany, Sweden, France and Spain. Europe produces equivalent to 90% of its consumption (2006). Germany produced ca 70% of its consumption, Spain 60% and Sweden 50% (2006). In Sweden there are 792 E85 filling stations and in France 131 E85 service stations with 550 more under construction.[81]

On Monday, September 17, 2007 the first ethanol fuel pump was opened in Reykjavik, Iceland. This pump is the only one of its kind in Iceland. The fuel is imported by Brimborg, a Volvo dealer, as a pilot to see how ethanol fueled cars work in Iceland.

In the Netherlands regular petrol with no bio-additives is slowly being outphased, since EU-legislation has been passed that requires the fraction of nonmineral origin to become minimum 5.75% of the total fuel consumption volume in 2010. This can be realised by substitutions in diesel or in petrol of any biological source; or fuel sold in the form of pure biofuel. (2007) There are only a few gas stations where E85 is sold, which is an 85% ethanol, 15% petrol mix.[112] Directly neighbouring country Germany is reported to have a much better biofuel infrastructure and offers both E85 and E50. Biofuel is taxed equally as regular fuel. However, fuel tanked abroad cannot be taxed and a recent payment receipt will in most cases suffice to prevent fines if customs check tank contents. (Authorities are aware of high taxation on fuels and cross-border fuel refilling is a well-known practice.)

Sweden

Sweden is the leading country in Europe regarding the use of ethanol as fuel, though it has to import most of the ethanol. All Swedish gas stations are required by an act of parliament to offer at least one alternative fuel, and every fifth car in Stockholm now drives at least partially on alternative fuels, mostly ethanol.[113] The number of bioethanol stations in Europe is highest in Sweden, with 1,200 stations[114] and a fleet of 116 thousand flexi-fuel vehicles as of July 2008.[115]

Stockholm will introduce a fleet of Swedish-made electric hybrid buses in its public transport system on a trial basis in 2008. These buses will use ethanol-powered internal-combustion engines and electric motors. The vehicles’ diesel engines will use ethanol.[113]

In order to achieve a broader use of biofuels several government incentives were implemented. Ethanol, as the other biofuels, were exempted of both, the CO2 and energy taxes until 2009, resulting in a 30% price reduction at the pump of E85 fuel over gasoline. Furthermore, other demand side incentives for flexifuel vehicle owners include a USD 1,800 bonus to buyers of FFVs, exemption from the Stockholm congestion tax, up to 20% discount on auto insurance, free parking spaces in most of the largest cities, lower annual registration taxes, and a 20% tax reduction for flexifuel company cars. Also, a part of the program, the Swedish Government ruled that 25% of their vehicle purchases (excluding police, fire and ambulance vehicles) must be alternative fuel vehicles.[114][114][116]; By the first months of 2008, this package of incentives resulted in sales of flexible-fuel cars representing 25% of new car sales.[114]

| Bioethanol stations |

||

|---|---|---|

| Country | Stations | No/106 persons |

| 1,200[114] | 131.26 | |

| 211[117] | 3.27 | |

| 193[118] | 2.35 | |

| 40[119] | 5.27 | |

| 29 | 6.84 | |

| 22 | 0.36 | |

Asia

China

China is promoting ethanol-based fuel on a pilot basis in five cities in its central and northeastern region, a move designed to create a new market for its surplus grain and reduce consumption of petroleum. The cities include Zhengzhou, Luoyang and Nanyang in central China's Henan province, and Harbin and Zhaodong in Heilongjiang province, northeast China. Under the program, Henan will promote ethanol-based fuel across the province by the end of this year. Officials say the move is of great importance in helping to stabilize grain prices, raise farmers' income and reducing petrol- induced air pollution.[120]

Thailand

Thailand already use 10% ethanol (E10) widely on big scale on the local market. Beginning in 2008 Thailand started with the sale of E20 and by late 2008 E85 flexible fuel vehicles were introduced with only two gas stations selling E85.[121]

Thailand is now converting some of the cassava stock hold by the government into fuel ethanol. Cassava-based ethanol productions are being ramped up to help manage the agricultural outputs of both cassava and sugar cane. With its abundant biomass resources, it is believed that the fuel ethanol program will be a new means of job creation in the rural areas while enhancing the balance sheet of fuel imports.

Australia

Legislation in Australia imposes a 10% cap on the concentration of fuel ethanol blends. Blends of 90% unleaded petrol and 10% fuel ethanol are commonly referred to as E10. E10 is available through service stations operating under the BP, Caltex, Shell and United brands as well as those of a number of smaller independents. Not surprisingly, E10 is most widely available closer to the sources of production in Queensland and New South Wales where Sugar Cane is grown. E10 is most commonly blended with 91 RON "regular unleaded" fuel. There is a requirement that retailers label blends containing fuel ethanol on the dispenser.

Due to ethanol's greater stability under pressure it is used by Shell in their 100 octane fuel. Similarly IFS add 10% ethanol to their 91 octane fuel, label it premium fuel and sell it more cheaply than regular unleaded. This is converse to the general practice of adding ethanol to a lesser quality fuel to bring its octane rating up to 91.

Some concern was raised over the use of ethanol blend fuels in petrol vehicles in 2003, yet manufacturers widely claimed that their vehicles were engined for such fuels. Since then there have been no reports of adverse affects to vehicles running on ethanol blended fuels.

Caribbean Basin

imports by country (2002–2007)[74] (Millions of U.S. liquid gallons) |

||||||

|---|---|---|---|---|---|---|

| Country | 2007 | 2006 | 2005 | 2004 | 2003 | 2002 |

| 188.8 | 433.7 | 31.2 | 90.3 | 0 | 0 | |

| 75.2 | 66.8 | 36.3 | 36.6 | 39.3 | 29.0 | |

| 73.3 | 38.5 | 23.7 | 5.7 | 6.9 | 4.5 | |

| 42.7 | 24.8 | 10.0 | 0 | 0 | 0 | |

| 39.3 | 35.9 | 33.4 | 25.4 | 14.7 | 12.0 | |

All countries in Central America, northern South America and the Caribbean are located in a tropical zone with suitable climate for growing sugar cane. In fact, most of these countries have a long tradition of growing sugar cane mainly for producing sugar and alcoholic beverages.

As a result of the guerilla movements in Central America, in 1983 the United States unilateral and temporarily approved the Caribbean Basin Initiative, allowing most countries in the region to benefit from several tariff and trade benefits. These benefits were made permanent in 1990 and more recently, these benefits were replaced by the Caribbean Basin Trade and Partnership Act, approved in 2000, and the Dominican Republic–Central America Free Trade Agreement that went to effect in 2008. All these agreements have allowed several countries in the region to export ethanol to the U.S free of tariffs.[63] Until 2004, the countries that benefited the most were Jamaica and Costa Rica, but as the U.S. began demanding more fuel ethanol, the two countries increased their exports and two others began exporting. In 2007, Jamaica, El Salvador, Trinidad & Tobago and Costa Rica exported together to the U.S. a total of 230.5 million gallons of ethanol, representing 54.1% of U.S. fuel ethanol imports. Brasil began exporting ethanol to the U.S. in 2004 and exported 188.8 million gallons representing 44.3% of U.S. ethanol imports in 2007. The remaining 1.6% imports that year came from Canada and China.[74]

In March 2007, "ethanol diplomacy" was the focus of President George W. Bush's Latin American tour, in which he and Brazil's president, Luiz Inacio Lula da Silva, were seeking to promote the production and use of sugar cane based ethanol throughout Latin America and the Caribbean. The two countries also agreed to share technology and set international standards for biofuels.[122] The Brazilian sugar cane technology transfer would allow several Central American, Caribbean and Andean countries to take advantage of their tariff-free trade agreements to increase or become exporters to the United States in the short-term.[123] Also, in August 2007, Brazil's President toured Mexico and several countries in Central America and the Caribbean to promote Brazilian ethanol technology.[124] The ethanol alliance between the U.S. and Brazil generated some negative reactions from Venezuela's President Hugo Chavez,[125] and by then Cuba's President, Fidel Castro, who wrote that "you will see how many people among the hungry masses of our planet will no longer consume corn." "Or even worse," he continued, "by offering financing to poor countries to produce ethanol from corn or any other kind of food, no tree will be left to defend humanity from climate change."'[126] Daniel Ortega, Nicaragua's President, and one of the preferencial recipients of Brazilian technical aid also voiced critics to the Bush plan, but he vowed support for sugar cane based ethanol during Lula's visit to Nicaragua.[127][128]

Colombia

Colombia's ethanol program began in 2002, based on a law approved in 2001 mandating a mix of 10% ethanol with regular gasoline, and the plan is to gradually reach a 25% blend in twenty-years. Sugar cane-based ethanol production began in 2005, when the law went into effect, and as local production was not enough to supply enough ethanol to the entire country's fleet, the program was implemented only on cities with more than 500,000 inhabitants, such as Cali, Pereira, and the capital city of Bogotá. All of the ethanol production comes from the Department of Valle del Cauca, Colombia's traditional sugar cane region. Cassava is the second source of ethanol, and potatoes and castor oil are also being studied.[129]

On March 2009 the Colombian government enacted a mandate to introduce E85 flexible-fuel cars. The executive decree applies to all gasoline-powered vehicles with engines smaller than 2.0 liters manufactured, imported, and commercialized in the country beginning in 2012, mandating that 60% of such vehicles must have flex-fuel engines capable of running with gasoline or E85, or any blend of both. By 2014 the mandatory quota is 80% and it will reach 100% by 2016. All vehicles with engines bigger than 2.0 liters must be E85 capable starting in 2013. The decree also mandates that by 2011 all gasoline stations must provide infrastructure to guarantee availability of E85 throughout the country.[130] The mandatory introduction of E85 flex-fuels has been controversial.[131][132]

Costa Rica

The government, based on the National Biofuel Program, established the mandatory use of all gasoline sold in Costa Rica with a blend of around 7.5% ethanol, starting in October 2008. The implementation phase follows a two year trial that took place in the provinces of Guanacaste and Puntarenas. The government expects to increase the percent of ethanol mixed with gasoline to 12% in the next 4 to 5 years. The Costa Rican government is pursuing this policy to lower the country's dependency of foreign oil and to reduce the amount of greenhouse gases produced. The plan also calls for an increase in ethanol producing crops and tax breaks for flex-fuel vehicles and other alternative fuel vehicles.[133] However, the introduction of the blend of 7% ethanol was postponed in September 2008 until the beginning of 2009. This delay was due to a request by the national association of fuel retailers to have more time available to adapt their fueling infrastructure.[134] Additional delays caused another postponement, as fueling stations were not ready yet for handling ethanol fuel, and now implementation is expected for November 2009.[135] [136]

Despite the official postponement, during the months of February and March 2009, ethanol in different blends was sold without warning to consumers, which was cause for complains. The national distribution company, RECOPE, explained that it had already bought 50,000 barrels of ethanol stored and ready for distribution, so it decided to used as an oxygenate in substitution of MTBE. Nevertheless, retail sales of E7 continue uninterrupted in the trial regions of Guanacaste and the Central Pacific for three years now.[137]

El Salvador

As a result of the cooperation agreement between the United States and Brazil, El Salvador was chosen in 2007 to lead a pilot experience to introduce state-of-the-art technology for growing sugar cane for production of ethanol fuel in Central America, as this technical bilateral cooperation is looking for helping Central American countries to reduce their dependence on foreign oil.[138]

Comparison of Brazil and the U.S.

Brazil's sugar cane-based industry is far more efficient than the U.S. corn-based industry. Brazilian distillers are able to produce ethanol for 22 cents per liter, compared with the 30 cents per liter for corn-based ethanol.[140] Sugarcane cultivation requires a tropical or subtropical climate, with a minimum of 600 mm (24 in) of annual rainfall. Sugarcane is one of the most efficient photosynthesizers in the plant kingdom, able to convert up to 2% of incident solar energy into biomass. Ethanol is produced by yeast fermentation of the sugar extracted from sugar cane.

Sugarcane production in the United States occurs in Florida, Louisiana, Hawaii, and Texas. In prime growing regions, such as Hawaii, sugarcane can produce 20 kg for each square meter exposed to the sun. The first three plants to produce sugar cane-based ethanol are expected to go online in Louisiana by mid 2009. Sugar mill plants in Lacassine, St. James and Bunkie were converted to sugar cane-based ethanol production using Colombian technology in order to make possible a profitable ethanol production. These three plants will produce 100 million gallons of ethanol within five years.[141]

U.S. corn-derived ethanol costs 30% more because the corn starch must first be converted to sugar before being distilled into alcohol. Despite this cost differential in production, in contrast to Japan and Sweden, the U.S. does not import much of Brazilian ethanol because of U.S. trade barriers corresponding to a tariff of 54-cent per gallon – a levy designed to offset the 45-cent per gallon blender's federal tax credit that is applied to ethanol no matter its country of origin.[53][142][143][144] One advantage U.S. corn-derived ethanol offers is the ability to return 1/3 of the feedstock back into the market as a replacement for the corn used in the form of Distillers Dried Grain.[45]

| Comparison of key characteristics between the ethanol industries in the United States and Brazil |

|||

|---|---|---|---|

| Characteristic | Units/comments | ||

| Feedstock |

|

|

Main cash crop for ethanol production, the US has less than 2% from other crops. |

| Total ethanol fuel production (2009) [2] |

|

|

Million U.S. liquid gallons |

| Total arable land [61] |

|

|

Million hectares. |

| Total area used for ethanol crop (2006)[45] |

|

|

Million hectares (% total arable)[61] |

| Productivity per hectare [45][51][61][145] |

|

|

Liters of ethanol per hectare. Brazil is 727 to 870 gal/acre (2006), US is 321 to 424 gal/acre (2003) |

| Energy balance (input energy productivity) [45][53][146] |

|

|

Ratio of the energy obtained from ethanol/energy expended in its production |

| Estimated GHG emissions reduction [45][147][148] |

|

|

% GHGs avoided by using ethanol instead of gasoline, using existing crop land (No ILUC). |

| Full life-cycle carbon intensity[149][150] |

|

|

Grams of CO2 equivalent released per MJ of energy produced, includes indirect land use changes.[148] |

| Estimated payback time for GHG emissions[151] |

|

|

Brazilian cerrado for sugarcane and US grassland for corn. Land use change scenarios by Fargione[152] |

| Flexible-fuel vehicles produced (autos and light trucks)[65][66][79] | 10.6 million | 9.3 million | Brazil as of June 2010 (FFVs use any blend up to E100). U.S. as of December 2009 (FFVs use E85). |

| Ethanol fueling stations in the country |

|

|

As % of total gas stations in the country. Brazil by December 2007.[153] U.S. by July 2010.[154] (170,000 total.[52]) |

| Ethanol's share in the gasoline market[56][57][155] |

|

|

As % of total consumption on a volumetric basis. Brazil as of April 2008. US as of December 2006. |

| Cost of production (USD/gallon) [51] |

|

|

2006/2007 for Brazil (22¢/liter), 2004 for U.S. (35¢/liter) |

| Government subsidy (in USD)[143][144] |

|

|

U.S. since 2009-01-01 as a tax credit. Brazilian ethanol production is no longer subsidized.(6) |

| Import tariffs (in USD)[142] |

|

|

Brazil does not import ethanol fuel since 2002.[156] The U.S. does in a regular basis. |

| Notes: (1) Only contiguous U.S., excludes Alaska. (2) Assuming no land use change.[148] (3) CARB estimate for Midwest corn ethanol. California's gasoline carbon intensity is 95.86 blended with 10% ethanol.[149][150] (4) Assuming direct land use change.[152] (5) If diesel-powered vehicles are included and due to ethanol's lower energy content by volume, bioethanol represented 16.9% of the road sector energy consumption in 2007.[157] (6) Brazilian ethanol production is no longer subsidized, but gasoline is heavily taxed favoring ethanol fuel consumption (~54% tax). By the end of July 2008, when oil prices were close to its latest peak and the Brazilian Real exchange rate to the US dollar was close to its most recent minimum, the average gasoline retail price at the pump in Brazil was USD 6.00 per gallon, while the average US price was USD 3.98 per gallon.[158] The latest gas retail price increase in Brazil occurred in late 2005, when oil price was at USD 60 per barrel.[159] (7) Brazilian import tax is 20% (FOB)[160] but in early 2010 it was temporarily cut to zero until 2011.[161] | |||

Environment

Energy balance

| Country | Type | Energy balance |

|---|---|---|

| Corn ethanol | 1.3 | |

| Sugarcane ethanol | 8 | |

| Biodiesel | 2.5 | |

| Cellulosic ethanol† | 2–36†† |

† experimental, not in commercial production

†† depending on production method

All biomass goes through at least some of these steps: it needs to be grown, collected, dried, fermented, and burned. All of these steps require resources and an infrastructure. The total amount of energy input into the process compared to the energy released by burning the resulting ethanol fuel is known as the energy balance (or "Net energy gain"). Figures compiled in a 2007 by National Geographic Magazine[47] point to modest results for corn ethanol produced in the US: one unit of fossil-fuel energy is required to create 1.3 energy units from the resulting ethanol. The energy balance for sugarcane ethanol produced in Brazil is more favorable, 1:8. Energy balance estimates are not easily produced, thus numerous such reports have been generated that are contradictory. For instance, a separate survey reports that production of ethanol from sugarcane, which requires a tropical climate to grow productively, returns from 8 to 9 units of energy for each unit expended, as compared to corn which only returns about 1.34 units of fuel energy for each unit of energy expended.[162]

Carbon dioxide, a greenhouse gas, is emitted during fermentation and combustion. However, this is canceled out by the greater uptake of carbon dioxide by the plants as they grow to produce the biomass.[163] When compared to gasoline, depending on the production method, ethanol releases less greenhouse gases.[164][165]

Air pollution

Compared with conventional unleaded gasoline, ethanol is a particulate-free burning fuel source that combusts with oxygen to form carbon dioxide, water and aldehydes. Gasoline produces 2.44 CO2 equivalent kg/l and ethanol 1.94 (this is 21% less CO2). The Clean Air Act requires the addition of oxygenates to reduce carbon monoxide emissions in the United States. The additive MTBE is currently being phased out due to ground water contamination, hence ethanol becomes an attractive alternative additive. Current production methods include air pollution from the manufacturer of macronutrient fertilizers such as ammonia.

A study by atmospheric scientists at Stanford University found that E85 fuel would increase the risk of air pollution deaths relative to gasoline by 9% in Los Angeles, USA: a very large, urban, car-based metropolis that is a worst case scenario.[166] Ozone levels are significantly increased, thereby increasing photochemical smog and aggravating medical problems such as asthma.[167][168]

Manufacture

In 2002, monitoring the process of ethanol production from corn revealed that they released VOCs (volatile organic compounds) at a higher rate than had previously been disclosed.[169] The Environmental Protection Agency (EPA) subsequently reached settlement with Archer Daniels Midland and Cargill, two of the largest producers of ethanol, to reduce emission of these VOCs. VOCs are produced when fermented corn mash is dried for sale as a supplement for livestock feed. Devices known as thermal oxidizers or catalytic oxidizers can be attached to the plants to burn off the hazardous gases.

Carbon dioxide

The calculation of exactly how much carbon dioxide is produced in the manufacture of bioethanol is a complex and inexact process, and is highly dependent on the method by which the ethanol is produced and the assumptions made in the calculation. A calculation should include:

- The cost of growing the feedstock

- The cost of transporting the feedstock to the factory

- The cost of processing the feedstock into bioethanol

Such a calculation may or may not consider the following effects:

- The cost of the change in land use of the area where the fuel feedstock is grown.

- The cost of transportation of the bioethanol from the factory to its point of use

- The efficiency of the bioethanol compared with standard gasoline

- The amount of Carbon Dioxide produced at the tail pipe.

- The benefits due to the production of useful bi-products, such as cattle feed or electricity.

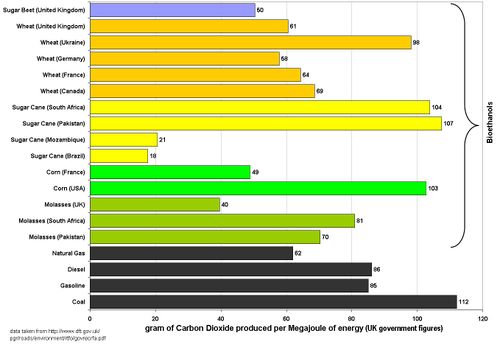

The graph on the right shows figures calculated by the UK government for the purposes of the Renewable transport fuel obligation.[170]

The January 2006 Science article from UC Berkeley's ERG, estimated reduction from corn ethanol in GHG to be 13% after reviewing a large number of studies. However, in a correction to that article released shortly after publication, they reduce the estimated value to 7.4%. A National Geographic Magazine overview article (2007)[47] puts the figures at 22% less CO2 emissions in production and use for corn ethanol compared to gasoline and a 56% reduction for cane ethanol. Carmaker Ford reports a 70% reduction in CO2 emissions with bioethanol compared to petrol for one of their flexible-fuel vehicles.[171]

An additional complication is that production requires tilling new soil[172] which produces a one-off release of GHG that it can take decades or centuries of production reductions in GHG emissions to equalize.[173] As an example, converting grass lands to corn production for ethanol takes about a century of annual savings to make up for the GHG released from the initial tilling.[172]

Change in land use

Large-scale farming is necessary to produce agricultural alcohol and this requires substantial amounts of cultivated land. University of Minnesota researchers report that if all corn grown in the U.S. were used to make ethanol it would displace 12% of current U.S. gasoline consumption.[174] There are claims that land for ethanol production is acquired through deforestation, while others have observed that areas currently supporting forests are usually not suitable for growing crops.[175][176] In any case, farming may involve a decline in soil fertility due to reduction of organic matter,[177] a decrease in water availability and quality, an increase in the use of pesticides and fertilizers, and potential dislocation of local communities.[178] However, new technology enables farmers and processors to increasingly produce the same output using less inputs.[174]

Cellulosic ethanol production is a new approach which may alleviate land use and related concerns. Cellulosic ethanol can be produced from any plant material, potentially doubling yields, in an effort to minimize conflict between food needs vs. fuel needs. Instead of utilizing only the starch by-products from grinding wheat and other crops, cellulosic ethanol production maximizes the use of all plant materials, including gluten. This approach would have a smaller carbon footprint because the amount of energy-intensive fertilisers and fungicides remain the same for higher output of usable material. The technology for producing cellulosic ethanol is currently in the commercialization stage.[12][13]

Many analysts suggest that, whichever ethanol fuel production strategy is used, fuel conservation efforts are also needed to make a large impact on reducing petroleum fuel use.[179]

Using Ethanol for Electricity

Converting biomass to electricity for charging electric vehicles may be a more "climate-friendly" transportation option than using biomass to produce ethanol fuel, according to an analysis published in Science in May. "You make more efficient use of the land and more efficient use of the plant biomass by making electricity rather than ethanol," said Elliott Campbell, an environmental scientist at the University of California at Merced, who led the research. "It's another reason that, rather than race to liquid biofuels, we should consider other uses of bio-resources."

For bioenergy to become a widespread climate solution, however, technological breakthroughs are necessary, analysts say. Researchers continue to search for more cost-effective developments in both cellulosic ethanol and advanced vehicle batteries.[180]

Health Costs of Ethanol Emissions

For each billion ethanol-equivalent gallons of fuel produced and combusted in the US, the combined climate-change and health costs are $469 million for gasoline, $472–952 million for corn ethanol depending on biorefinery heat source (natural gas, corn stover, or coal) and technology, but only $123–208 million for cellulosic ethanol depending on feedstock (prairie biomass, Miscanthus, corn stover, or switchgrass).[181]

Efficiency of common crops

As ethanol yields improve or different feedstocks are introduced, ethanol production may become more economically feasible in the US. Currently, research on improving ethanol yields from each unit of corn is underway using biotechnology. Also, as long as oil prices remain high, the economical use of other feedstocks, such as cellulose, become viable. By-products such as straw or wood chips can be converted to ethanol. Fast growing species like switchgrass can be grown on land not suitable for other cash crops and yield high levels of ethanol per unit area.[47]

| Crop | Annual yield (Liters/hectare, US gal/acre) | Greenhouse-gas savings vs. petrol[a] |

Comments | |

|---|---|---|---|---|

| Miscanthus | 7300 L/ha, 780 g/acre |

37%–73% | Low-input perennial grass. Ethanol production depends on development of cellulosic technology. | |

| Switchgrass | 3100–7600 L/ha, 330–810 g/acre |

37%–73% | Low-input perennial grass. Ethanol production depends on development of cellulosic technology. Breeding efforts underway to increase yields. Higher biomass production possible with mixed species of perennial grasses. | |

| Poplar | 3700–6000 L/ha, 400–640 g/acre |

51%–100% | Fast-growing tree. Ethanol production depends on development of cellulosic technology. Completion of genomic sequencing project will aid breeding efforts to increase yields. | |

| Sugar cane | 6800–8000 L/ha[45][51][61][145], 727–870 g/acre |

87%–96% | Long-season annual grass. Used as feedstock for most bioethanol produced in Brazil. Newer processing plants burn residues not used for ethanol to generate electricity. Only grows in tropical and subtropical climates. | |

| Sweet sorghum | 2500–7000 L/ha, 270–750 g/acre |

No data | Low-input annual grass. Ethanol production possible using existing technology. Grows in tropical and temperate climates, but highest ethanol yield estimates assume multiple crops per year (only possible in tropical climates). Does not store well.[182][183][184][185] | |

| Corn | 3100–4000 L/ha[45][51][61][145], 330–424 g/acre |

10%–20% | High-input annual grass. Used as feedstock for most bioethanol produced in USA. Only kernels can be processed using available technology; development of commercial cellulosic technology would allow stover to be used and increase ethanol yield by 1,100 - 2,000 litres/ha. | |

| Source (except those indicated): Nature 444 (December 7, 2006): 673-676. [a] - Savings of GHG emissions assuming no land use change (using existing crop lands). |

||||

Reduced petroleum imports and costs

One rationale given for extensive ethanol production in the U.S. is its benefit to energy security, by shifting the need for some foreign-produced oil to domestically produced energy sources.[186][187] Production of ethanol requires significant energy, but current U.S. production derives most of that energy from coal, natural gas and other sources, rather than oil.[188] Because 66% of oil consumed in the U.S. is imported, compared to a net surplus of coal and just 16% of natural gas (2006 figures),[189] the displacement of oil-based fuels to ethanol produces a net shift from foreign to domestic U.S. energy sources.

According to a 2008 analysis by Iowa State University, the growth in US ethanol production has caused retail gasoline prices to be US $0.29 to US $0.40 per gallon lower than would otherwise have been the case.[190]

Criticism and controversy

There are various current issues with ethanol production and use, which are presently being discussed in the popular media and scientific journals. These include: the effect of moderating oil prices, the "food vs fuel" debate, carbon emissions levels, sustainable biofuel production, deforestation and soil erosion, impact on water resources, human rights issues, poverty reduction potential, ethanol prices, energy balance and efficiency, and centralised vs. decentralised production models.

Food vs fuel is about the price and availability impact of diverting farmland or crops for ethanol production to the detriment of the food supply. The debate is internationally controversial, with valid arguments on all sides of this ongoing debate. There is disagreement about how significant this is, what is causing it, what the impact is, and what can or should be done about it.[191][192][193][194]

Fuel system problems

Several of the outstanding ethanol fuel issues are linked specifically to fuel systems. Fuels with more than 10% ethanol are not compatible with non E85-ready fuel system components and may cause corrosion of iron components.[195][196] Ethanol fuel can negatively affect electric fuel pumps by increasing internal wear,[196] cause undesirable spark generation,[197] and is not compatible with capacitance fuel level gauging indicators and may cause erroneous fuel quantity indications in vehicles that employ that system.[198] It is also not always compatible with marine craft, especially those that use fiberglass fuel tanks.[199][200] Ethanol is also not used in aircraft for these same reasons.

Using 100% ethanol fuel decreases fuel-economy by 15-30% over using 100% gasoline; this can be avoided using certain modifications that would, however, render the engine inoperable on regular petrol without the addition of an adjustable ECU.[201] Tough materials are needed to accommodate a higher compression ratio to make an ethanol engine as efficient as it would be on petrol; these would be similar to those used in diesel engines which typically run at a CR of 20:1,[202] vs. about 8-12:1 for petrol engines.[203]

In April 2008 the German environmental minister cancelled a proposed 10% ethanol fuel scheme citing technical problems: too many older cars in Germany are unequipped to handle this fuel. Ethanol levels in fuel will remain at 5%.[204]

Other non-transport uses

There is still extensive use of kerosene for lighting and cooking in less developed countries, and ethanol can have a role in reducing petroleum dependency in this use too. A non profit named Project Gaia seeks to spread the use of ethanol stoves to replace wood, charcoal and kerosene.[205] There is also potential for bioethanol replacing some kerosene use in domestic lighting from feedstocks grown locally. A 50% ethanol water mixture has been tested in specially designed stoves and lanterns for rural areas.

Bibliography

- J. Goettemoeller, A. Goettemoeller (2007). Sustainable Ethanol: Biofuels, Biorefineries, Cellulosic Biomass, Flex-Fuel Vehicles, and Sustainable Farming for Energy Independence (Brief and comprehensive account of the history, evolution and future of ethanol). Prairie Oak Publishing,Maryville, Missouri. ISBN 9780978629304.

- The Worldwatch Institute (2007). Biofuels for Transport: Global Potential and Implications for Energy and Agriculture (Global view, includes country study cases of Brazil, China, India and Tanzania). Earthscan Publications Ltd., London, U.K.. ISBN 9781844074228.

See also

- Alcohol fuel

- Biobutanol, a gasoline replacement.

- Bioconversion of biomass to mixed alcohol fuels

- Biofuel

- Biomass

- Cellulosic ethanol

- Corn Ethanol

- Common ethanol fuel mixtures

- Comparison of automobile fuel technologies

- DMF (potential ethanol competitor biofuel)

- Dimethyl ether

- Energy crop

- Energy development

- Ethanol effect

- Ethanol from coal

- Flexible-fuel vehicle

- Food vs fuel

- Gasoline gallon equivalent

- Indirect land use change impacts of biofuels

- Issues relating to biofuels

- Hydrogen fuel

- Liquid fuels

- List of energy topics

- Low-carbon fuel standard

- P-series fuels

- Timeline of alcohol fuel

References

- ↑ "Towards Sustainable Production and Use of Resources: Assessing Biofuels". United Nations Environment Programme. 2009-10-16. http://www.unep.fr/scp/rpanel/pdf/Assessing_Biofuels_Full_Report.pdf. Retrieved 2009-10-24.

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 "2010 Ethanol Industry Outlook: Cimate of Opportunity". Renewable Fuels Association. 2010. http://www.ethanolrfa.org/industry/outlook/RFAoutlook2010_fin.pdf. Retrieved 2010-04-17.

- ↑ Worldwatch Institute and Center for American Progress (2006). American energy: The renewable path to energy security

- ↑ "Portaria Nº 143, de 27 de Junho de 2007" (in Portuguese). Ministério da Agricultura, Pecuária e Abastecimento. http://extranet.agricultura.gov.br/sislegis-consulta/consultarLegislacao.do?operacao=visualizar&id=17886. Retrieved 2008-10-05.

- ↑ 5.0 5.1 Agência Estado (2010-03-04). "Brasil alcança marca de 10 milhões de carros flex" (in Portuguese). Veja (magazine). http://www.abril.com.br/noticias/economia/brasil-alcanca-marca-10-milhoes-carros-flex-940397.shtml. Retrieved 2010-03-07.

- ↑ 6.0 6.1 "Automakers in Brazil Hit 10M Flex-Fuel Vehicle Mark; Brazilian Sugarcane Association Urges Global Dissemination". Green Car Congress. 2010-03-06. http://www.greencarcongress.com/2010/03/anfavea-20100306.html#more=. Retrieved 2010-03-09.

- ↑ Deforestation diesel – the madness of biofuel

- ↑ Youngquist, W. Geodestinies, National Book company, Portland, OR, 499p.

- ↑ The dirty truth about biofuels

- ↑ 10.0 10.1 Biofuels look to the next generation

- ↑ O. R. Inderwildi, D. A. King (2009). "Quo Vadis Biofuels". Energy & Environmental Science 2: 343. doi:10.1039/b822951c.

- ↑ 12.0 12.1 Biotechnology Industry Organization (2007). Industrial Biotechnology Is Revolutionizing the Production of Ethanol Transportation Fuel pp. 3-4.

- ↑ 13.0 13.1 International Energy Agency (2006). World Energy Outlook 2006 p. 8.

- ↑ meti.go.jp file g30819b40j

- ↑ (grainscouncil.com, Biofuels_study 268 kB pdf, footnote, p 6)

- ↑ ethanolproducer.com, article 2077

- ↑ Algae farm in Mexico to produce ethanol in '09

- ↑ "New Enzyme for More Efficient Corn Ethanol Production". Green Car Congress. 2005-06-30. http://www.greencarcongress.com/2005/06/new_enzyme_for_.html. Retrieved 2008-01-14.

- ↑ "Modern Corn Ethanol plant description" (PDF). http://www.bioethanol.ru/images/bioethanol/Fuel%20ethanol%20production%20-%20Katzen.pdf.

- ↑ 20.0 20.1 www.eere.energy.gov Energy.gov site

- ↑ 21.0 21.1 www.eia.doe.gov Alternative Fuel Efficiencies in Miles per Gallon

- ↑ 22.0 22.1 washington.edu, course, October 22 v2

- ↑ Efficiency Improvements Associated with Ethanol-Fueled Spark-Ignition Engines

- ↑ N. Stauffer (2006-10-25). "MIT's pint-sized car engine promises high efficiency, low cost". MIT. http://web.mit.edu/newsoffice/2006/engine.html. Retrieved 2008-01-14.

- ↑ Squeezing More Out of Ethanol

- ↑ MIT Study

- ↑ SAE Paper 2001-01-2901

- ↑ M. Brusstar, M. Bakenhus. "Economical, High-Efficiency Engine Technologies for Alcohol Fuels" (PDF). U. S. Environmental Protection Agency. http://www.epa.gov/otaq/presentations/epa-fev-isaf-no55.pdf. Retrieved 2008-01-14.

- ↑ "Scania continues renewable fuel drive, New highly efficient diesel ethanol engine-- ready to cut fossil CO2 emissions by 90%" Scania PRESSInfo, May 21, 2007

- ↑ "England receives ethanol buses Brian Warshaw, Ethanol Producer, March 21, 2008

- ↑ Roman M. Balabin, et al. (2007). "Molar enthalpy of vaporization of ethanol–gasoline mixtures and their colloid state". Fuel 86: 323. doi:10.1016/j.fuel.2006.08.008.

- ↑ "Sustainable biofuels: prospects and challenges" (PDF). The Royal Society. January 2008. http://royalsociety.org/displaypagedoc.asp?id=28632. Retrieved 2008-09-27. Policy document 01/08. See 4.3.1 Vapour pressure and bioethanol and Figure 4.3 for the relation between ethanol content and vapor pressure.

- ↑ Ethanol Promotion and Information Council (2007-02-27). "When is E85 not 85 percent ethanol? When it’s E70 with an E85 sticker on it". AutoblogGreen. http://www.autobloggreen.com/2007/02/27/when-is-e85-not-85-percent-ethanol-when-its-e70-with-an-e85-st/. Retrieved 2008-08-24.

- ↑ 34.0 34.1 "Ethanol fuel and cars". Interesting Energy Facts. http://interestingenergyfacts.blogspot.com/2008/09/ethanol-fuel-and-cars.html. Retrieved 2008-09-23.

- ↑ Vägverket (Swedish Road Administration) (2007-05-30). "Swedish comments on Euro 5/6 comitology version 4, 30 May 2007: Cold Temperature Tests For Flex Fuel Vehicles" (PDF). European Commission. http://ec.europa.eu/enterprise/automotive/mveg_meetings/subgroup_euro/meeting9/swedish_comments_on_draft_v4.pdf. Retrieved 2008-09-23.

- ↑ "Here comes the 'Flex' vehicles third generation" (in Portuguese) (PDF). Revista Brasileira de BioEnergia (Centro Nacional de Referência em Biomassa (Cenbio)). August 2008. http://cenbio.iee.usp.br/download/revista/RBB3.pdf. Retrieved 2008-09-23. Ano 2, No. 3 (every article is presented in both English and Portuguese)

- ↑ Agência Estado (2008-06-10). "Bosch investe na segunda geração do motor flex" (in Portuguese). Gazeta do Povo. http://portal.rpc.com.br/gazetadopovo/economia/conteudo.phtml?tl=1&id=774927&tit=. Retrieved 2008-09-23.

- ↑ Q. Rodas (March 2009). "Volkswagen Polo E-Flex" (in Portuguese). Editora Abril. http://quatrorodas.abril.com.br/carros/lancamentos/volkswagen-polo-e-flex-425390.shtml. Retrieved 2003-03-12.

- ↑ "Volks lança sistema que elimina tanquinho de gasolina para partida a frio" (in Portuguese). UNICA. 2009-03-12. http://www.unica.com.br/noticias/show.asp?nwsCode=0548296D-D8CE-4E25-9973-BF18D30BDFFD. Retrieved 2003-03-12.

- ↑ This is shown for 25°C (77°F) in a gasoline-ethanol-water phase diagram, Fig 13 of Päivi Aakko; Nils-Olof Nylund. "Technical View on Biofuels for Transportation – Focus on Ethanol End-Use Aspects" (PDF). http://web.archive.org/web/20071203173845/www.vtt.fi/inf/julkaisut/muut/2004/EtOH_VTT5100_03.pdf. Retrieved 2008-01-14.

- ↑ as shown in Figure 1 of http://www.epa.gov/OMS/regs/fuels/rfg/waterphs.pdf

- ↑ www.eia.doe.gov DOE FAQ

- ↑ "Ethanol in Petrol". Royal Automobile Association of South Australia. February 2004. http://www.raa.net/page.asp?TerID=146. Retrieved 2007-04-29.

- ↑ http://www.epa.gov EPA Info

- ↑ 45.00 45.01 45.02 45.03 45.04 45.05 45.06 45.07 45.08 45.09 45.10 45.11 45.12 J. Goettemoeller, A. Goettemoeller (2007). Sustainable Ethanol: Biofuels, Biorefineries, Cellulosic Biomass, Flex-Fuel Vehicles, and Sustainable Farming for Energy Independence. Prairie Oak Publishing, Maryville, Missouri. p. 42. ISBN 9780978629304.

- ↑ http://www.fueleconomy.gov EPA Mileage

- ↑ 47.0 47.1 47.2 47.3 47.4 47.5 47.6 Green Dreams J.K. Bourne JR, R. Clark National Geographic Magazine October 2007 p. 41 Article

- ↑ "Home Mini-Refinery Makes Ethanol & Biodiesel Simultaneously". Gas2.0. 2008-11-04. http://gas2.org/2008/11/04/home-mini-refinery-makes-ethanol-biodiesel-simultaneously/#more-1219. Retrieved 2008-11-04.

- ↑ "Micro Fueler Is First Ethanol Kit for Brewing Backyard Biofuels on the Cheap". PopularMechanics. 2008-05-08. http://www.popularmechanics.com/blogs/science_news/4262690.html. Retrieved 2008-05-08.

- ↑ F.O. Licht. "2007 and 2008 World Fuel Ethanol Production". Renewable Fuels Association. http://web.archive.org/web/20080408091334/http://www.ethanolrfa.org/industry/statistics/. Retrieved 2010-04-17.

- ↑ 51.0 51.1 51.2 51.3 51.4 51.5 D. Budny, P. Sotero (2007-04). "Brazil Institute Special Report: The Global Dynamics of Biofuels" (PDF). Brazil Institute of the Woodrow Wilson Center. http://www.wilsoncenter.org/topics/pubs/Brazil_SR_e3.pdf. Retrieved 2008-05-03.

- ↑ 52.0 52.1 52.2 J. Inslee, H. Bracken (2007). "6. Homegrown Energy". Apollo's Fire. Island Press, Washington, D.C.. pp. 153–155, 160–161. ISBN 9781597261753.

- ↑ 53.0 53.1 53.2 Larry Rother (2006-04-10). "With Big Boost From Sugar Cane, Brazil Is Satisfying Its Fuel Needs". The New York Times. http://www.nytimes.com/2006/04/10/world/americas/10brazil.html?pagewanted=1&sq=Bush%20Brazil%20ethanol&st=nyt&scp=5. Retrieved 2008-04-28.

- ↑ "2007 Brazilian Energy Balance: Executive Summary". Ministério de Minas e Energia do Brasil. http://www.mme.gov.br/site/menu/select_main_menu_item.do?channelId=1432&pageId=14493. Retrieved 2008-05-10. Table 2. Report is based in 2006 data

- ↑ D. S. Shurtleff (2008-05-07). "Brazil's energy plan examined". The Washington Times. http://www.washingtontimes.com/article/20080507/COMMENTARY/381443705/1012/commentary. Retrieved 2008-05-10.

- ↑ 56.0 56.1 Agência Brasil (2008-07-15). "ANP: consumo de álcool combustível é 50% maior em 2007" (in Portuguese). Invertia. http://br.invertia.com/noticias/noticia.aspx?idNoticia=200807152306_ABR_77211977. Retrieved 2008-08-09.

- ↑ 57.0 57.1 Gazeta Mercantil (2008). "ANP estima que consumo de álcool supere gasolina" (in Portuguese). Agropecuária Brasil. http://www.agropecuariabrasil.com.br/anp-estima-que-consumo-de-alcool-supere-gasolina/. Retrieved 2008-08-09.

- ↑ America and Brazil Intersect on Ethanol Renewable Energy Access, 15 May 2006.

- ↑ How to manage our oil addiction - CESP

- ↑ New Rig Brings Brazil Oil Self-Sufficiency Washington Post, 21 April 2006.

- ↑ 61.0 61.1 61.2 61.3 61.4 61.5 J. Duailibi (2008-04-27). "Ele é o falso vilão" (in Portuguese). Veja Magazine. http://veja.abril.com.br/300408/p_058.shtml. Retrieved 2008-05-03.

- ↑ 62.0 62.1 American Council for an Energy-Efficient Economy (1999). Policies for a More Sustainable Energy Future

- ↑ 63.0 63.1 Luiz A. Horta Nogueira (2004-03-22). "Perspectivas de un Programa de Biocombustibles en América Central: Proyecto Uso Sustentable de Hidrocarburos" (in Spanish) (PDF). Comisión Económica para América Latina y el Caribe (CEPAL). http://www.agrocombustibles.org/conceptos/CepalBiocombustiblesLac2004.pdf. Retrieved 2008-05-09.

- ↑ William Lemos (2007-11-12). "Brazil's flex-fuel car production rises, boosting ethanol consumption to record highs". ICIS chemical business. http://www.icis.com/Articles/2007/11/12/9077311/brazils-flex-fuel-car-production-rises-boosting-ethanol-consumption-to-record-highs.html. Retrieved 2008-05-03.