Anvil

An anvil is a basic tool. In the simplest terms it is a block with a hard surface on which another object is struck. The inertia of the anvil allows the energy of the striking tool to be transferred to the work piece. In most cases the anvil is used as a forging tool. Before the advent of modern welding technology, it was a primary tool of metal workers.

The great majority of modern anvils are made from steel though other types exist.

Because anvils are very ancient tools and were at one time very commonplace, they have acquired symbolic meaning beyond their use as utilitarian objects.

Contents |

History

In the past anvils were first made of stone as a lithic stone tool, then bronze, and later wrought iron. As steel became more readily available, anvils were faced with it. This was done to give the anvil a hard face and to stop the anvil from deforming from impact. Many regional styles of anvils evolved through time from the simple block that was first used by smiths. The majority of anvils found today in the US are based on the London pattern anvil of the mid-19th century.

The wrought iron steel faced anvil was produced up until the early 20th century. Through the 19th and very early 20th centuries, this method of construction evolved to produce extremely high quality anvils. The basic process involved forge welding billets of wrought iron together to produce the desired shape. The sequence and location of the forge welds varied between different anvil makers and the kind of anvil being made. At the same time cast iron anvils with steel faces were being made in the United States. At the dawn of the 20th century solid cast steel anvils began to be produced, as well as two piece forged anvils made from closed die forgings. Modern anvils are generally made entirely from steel.

The concept of an anvil may predate humanity. Chimpanzees have been observed using large sticks as hammers to crack nuts, using logs as anvils.

There are many references to anvils in ancient Greek and Egyptian writings, including Homer's works. They have been found at the Calico Early Man Site in North America.

Anvils have since lost their former commonness, along with the smiths who used them. Mechanized production has made cheap and abundant manufactured goods readily available. The one-off hand-made products of the blacksmith are less economically viable in the modern world, while in the past they were an absolute necessity. However, anvils are still used by blacksmiths and metal workers of all kinds in producing custom work. They are also essential to the work done by farriers.

Structure

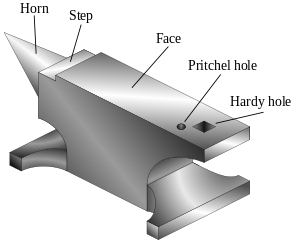

The primary work surface of the anvil is known as the face. It is generally made of hardened steel and should be flat and smooth with rounded edges for most work. Any marks on the face will be transferred to the work. Also, sharp edges tend to cut into the metal being worked and may cause cracks to form in the workpiece. The face is hardened and tempered to resist the blows of the smith's hammer so the anvil face does not deform under repeated use. A hard anvil face also reduces the amount of force lost in each hammer blow. Hammers should never directly strike the anvil face, as they may damage it.

The horn of the anvil is a conical projection used to form various round shapes, and is generally unhardened steel or iron. The horn is used mostly in bending operations. It also is used by some smiths as an aid in drawing out stock, "making it longer and thinner". Some anvils, mainly European, are made with two horns, one square and one round. Also, some anvils are made with side horns or clips for specialized work.

The step or pad, commonly referred to as the table of the anvil, is used for cutting; its purpose is to prevent damaging the face by conducting such operations there, although most professional smiths shun this practice, as it can damage the anvil.

The hardy hole is a square hole into which specialized forming and cutting tools, called hardy tools, are placed. It is also used in punching and bending operations.

The pritchel hole is a small round hole that is present on most modern anvils. Some anvils have more than one. It is used mostly for punching. At times, smiths will fit a second tool to this hole to allow the smith more flexibility when using more than one anvil tool.

Placement

An anvil needs to be placed upon a sturdy base made from an impact resistant material. It requires being fastened firmly to the base so it will not move when struck with a hammer. A loose anvil is extremely unsafe, as it can fall off the base. Common methods of attaching an anvil are spikes, chains, steel or iron straps, clips, bolts where there are holes provided, and cables. A smith would use whatever was at hand, as long as it held the anvil firmly in place. It is a poor idea to weld an anvil to a base or drill holes into it, as many anvils are antiques; when properly used and cared for, they can last generations. The anvil should be placed as near to the forge as is convenient, generally no more than one step from the forge to prevent heat loss in the work piece.

The most common base traditionally was a hard wood log or large timber buried several feet into the floor of the forge shop floor. This was done to make the anvil immobile when heavy forging and bending were done upon the anvil. In the industrial era cast iron bases became available. They had the advantage of adding additional weight to the anvil, making it more stable while making the anvil movable. These bases are highly sought after by collectors today. When concrete became widely available, there was a trend to make steel reinforced anvil bases by some smiths, though this practice has largely been abandoned. In more modern times many anvils have been placed upon bases fabricated from steel, oftentimes a short thick section of large I-Beam. In addition, bases have been made from dimensional lumber bolted together to form a large block or steel drums full of oil-saturated sand to provide a damping effect.

Types

There are many designs for anvils, which are often tailored for a specific purpose or to meet the needs of a particular smith. Such designs have originated in diverse geographic locations.

The common blacksmith's anvil is made of either forged or cast steel, tool steel, or wrought iron (cast iron anvils are generally shunned, as they are too brittle for repeated use, and do not return the energy of a hammer blow like steel). Historically, some anvils have been made with a smooth top working face of hardened steel welded to a cast iron or wrought iron body, though this manufacturing method is no longer in use. It has at one end a projecting conical bick (beak, horn) used for hammering curved work pieces. The other end is typically called the heel. Occasionally the other end is also provided with a bick, partly rectangular in section. Most anvils made since the late 18th century also have a hardy hole and a pritchel hole where various tools, such as the anvil-cutter or hot chisel, can be inserted and held by the anvil. Some anvils have several hardy and pritchel holes, to accommodate a wider variety of hardy tools and pritchels. An anvil may also have a softer pad for chisel work.

An anvil for a power hammer is usually supported on a massive anvil block, sometimes weighing over 800 tons for a 12-ton hammer; this again rests on a strong foundation of timber and masonry or concrete.

An anvil may have a marking indicating its weight, manufacturer, or place of origin. American-made anvils were often marked in pounds. European anvils are sometimes marked in kilograms. English anvils were often marked in hundredweight, the marking consisting of three numbers, indicating hundredweight, quarter hundredweight and pounds. For example, a 3-1-5, if such an anvil existed, would be 3x112 lb + 1x28 lb + 5 lb = 369 lb ~= 168 kg.

Cheap anvils made from inferior steel or cast iron, which are unsuitable for serious use, have been derisively referred to as "ASOs", or "Anvil Shaped Objects"[1]. Some amateur smiths have used a piece of railroad track as a makeshift anvil.

Top quality modern anvils are made of cast or forged tool steel and are heat treated for optimum hardness and toughness.

A metalworking vise may have a small anvil integrated in its design.

Anvils in art and entertainment

Historically

Anvil firing is the practice of firing an anvil into the air using gunpowder. It has been popular in California, the eastern United States and the southern United States, much like how fireworks are used today. There is a growing interest in re-enacting this "ancient tradition" in the USA, which has now spread to England.[2]

The Africian Methodist Episcopal Church (AME) has the anvil in their logo. The AME's first services were held in a blacksmith shop.

Television and film

A typical metalworker's anvil, with horn at one end and flat face at the other, is a standard prop for cartoon gags, as the epitome of a heavy and clumsy object that is perfect for dropping onto a villain. This visual metaphor is common, for example, in Warner Brothers' Looney Tunes and Merrie Melodies shorts, such as those with Wile E. Coyote and Road Runner.

Animaniacs made frequent gags with this during the 1996-1997 season, even having a kingdom named Anvilania, whose sole national product is anvils.

Anvils and ASO's were mentioned and shown in the Mythbusters episode on trying to see if hammers would shatter if made brittle enough. The Mythbusters spoke of the distinction between anvils and anvil shaped objects.

Musical instruments

Anvils have been used as percussion instruments in several famous musical compositions, including:

- Giuseppe Verdi: Il Trovatore, featuring the famous "Anvil Chorus"

- Richard Wagner: Der Ring des Nibelungen in Das Rheingold in scene 3, using 18 anvils tuned in F in three octaves, and Siegfried in act I, notably Siegfried's "Forging Song" (Nothung! Nothung! Neidliches Schwert!)

- Josef Strauss: Feuerfest!, op. 269

- Daniel Auber: opera Le Maçon

- Gustav Holst: Second Suite in F for Military Band, which includes a movement titled "Song of the Blacksmith"

- Aaron Copland: Symphony No. 3

- Arnold Bax: Symphony No. 3

- William Walton: Belshazzar's Feast

- Edgard Varèse: Ionisation

- Carl Orff: Antigone

- Benjamin Britten: The Burning Fiery Furnace

- Juan María Solare: Veinticinco de agosto, 1983 and Un ángel de hielo y fuego

- Nicholas Hooper: Harry Potter and the Half-Blood Prince

- James Horner: Used it extensively in Aliens, and his other films like Flightplan, The Forgotten and Titanic

- Howard Shore: The Lord of the Rings film trilogy

- Don Davis: The Matrix trilogy

- Albert Parlow: "Anvil Polka"

- Louis Andriessen: De Materie (Part I), which features an extended solo for two anvils

- Fear Factory: "Body Hammer", which features the sound of a hammer striking an anvil as percussion.

- Judas Priest: "Between The Hammer And The Anvil" which features the sound of a hammer striking an anvil for dramatic effect.

- The Beatles: "Maxwell's Silver Hammer" makes prominent use of the anvil. Beatles road manager Mal Evans played the anvil.

- John Williams: film music Jaws

- Kansas: "On the Other Side" featured some use of the anvil. Kansas violinist Robby Steinhardt played the anvil on the track.

- Jean Michel Jarre: On the overture of the disc "Revolutions".

See also

- Blacksmith

- Forge

- Silversmith

- Smith

References

- ↑ http://www.anvilfire.com/index.php?bodyName=/FAQs/ebay_fraud_ASO.htm Ebay Fraud: Purchasing an ASO (Anvil Shaped Object)

- ↑ "St Clements Day Celebrations". http://www.okehamptonpeople.co.uk/news/Blacksmiths-celebrate-St-Clement-s-Day-Sticklepath-s-Finch-Foundry-November-21st/article-1523527-detail/article.html.

Further reading

- Andrews, Jack (1994). New Edge of the Anvil. ISBN 1-879535-09-2.

- Hrisoulas, Jim (1987). The Complete Bladesmith: Forging Your Way to Perfection. Boulder, Colorado: Paladin Press. ISBN 0-87364-430-1.

- Postman, Richard (1998). Anvils In America. ISBN 0-9663256-0-5.

External links

![]() Chisholm, Hugh, ed (1911). "Anvil". Encyclopædia Britannica (Eleventh ed.). Cambridge University Press.

Chisholm, Hugh, ed (1911). "Anvil". Encyclopædia Britannica (Eleventh ed.). Cambridge University Press.

|

|||||||||||||||||||||||||||||||