Zinc oxide

| Zinc Oxide | |

|---|---|

|

|

|

|

| Other names | Zinc white, calamine Zincum oxydatum |

| Identifiers | |

| CAS number | 1314-13-2 |

| Properties | |

| Molecular formula | ZnO |

| Molar mass | 81.4084 g/mol |

| Appearance | White solid |

| Density | 5.606 g/cm³, solid |

| Melting point |

1975 °C (decomposes) |

| Solubility in water | 1.6 g/L at 28°C |

| Thermochemistry | |

| Std enthalpy of formation ΔfH |

−348.0 kJ/mol |

| Standard molar entropy S |

43.9 J.K−1.mol−1 |

| Hazards | |

| EU classification | Dangerous for the environment (N) |

| NFPA 704 |

1

|

| R-phrases | R20, R36, R37. |

| S-phrases | S60, S61. |

| Related compounds | |

| Other anions | Zinc sulfide Zinc selenide Zinc telluride |

| Other cations | Cadmium oxide Mercury oxide |

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C, 100 kPa) Infobox references |

|

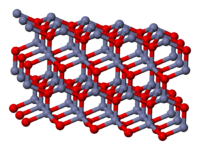

Zinc oxide is a chemical compound with the formula ZnO. It is nearly insoluble in water but soluble in acids and bases. It occurs as white hexagonal, wurtzite type crystals having 6mm of symmetry or a white powder commonly known as zinc white. Zinc oxide occurs in nature as the mineral zincite. Crystalline zinc oxide exhibits the piezoelectric effect and is thermochromic, changing from white to yellow when heated.

Contents |

Chemical properties

Zinc oxide decomposes into zinc vapor and oxygen only at around 1975 °C, reflecting its considerable stability. Heating with carbon converts the oxide into zinc[1]:

- ZnO + C → Zn + CO

Upon heating with magnesium, zinc oxide is reduced explosively. It remains white when exposed to hydrogen sulfide, where it converts to the sulfide:

- ZnO + H2S → ZnS + H2O

Single-crystalline ZnO is almost transparent.

Production

- See also: Zinc smelting

Zinc oxide is produced by two main processes:

French process

Metallic zinc is melted in a graphite crucible and vaporized above 907 °C. Zinc vapor instantaneously reacts with the oxygen in the air to give ZnO, accompanied by a drop in its temperature and bright luminescence. Zinc oxide particles are transported into a cooling duct and collected in a bag house. This indirect method is commonly known as the French process (FP) which was popularised by LeClaire (France) in 1844. A typical FP, zinc oxide normally consists of agglomerated zinc oxide particles with an average size of 0.1 micrometres to a few micrometres. By weight, most of the world's zinc oxide is manufactured via French process and major applications involve industries related to rubber, varistors, sunscreens, paints, healthcare, and poultry nutrients. Recent developments involve acicular nanostructures (rods, wires, tripods, tetrapods, plates) synthesized using a modified French process known as catalyst-free combust-oxidized mesh (CFCOM) process. Acicular nanostructures usually have micrometre-length nanorods with nanometric diameters (below 100 nm).

The so-called direct method is related to the FP. In this process, zinc ores or roasted sulfide concentrates are mixed with coal. In a reduction furnace, ore is reduced to metallic zinc and the vaporized zinc is allowed to react with oxygen to form zinc oxide.

American process

In this process ore of zinc (zinc ash) is dissolved (as ZnCl2) and precipitated with alkali. Zinc oxide made from this process is known as "Active Zinc Oxide".

Applications

Medical applications

Zinc oxide lozenges used to be a popular over-the-counter cold remedy, but numerous studies have failed to demonstrate any significant effect.[2] Zinc oxide in a mixture with about 0.5% iron(III) oxide (Fe2O3) is called calamine and is used in calamine lotion. There are also two minerals, zincite and hemimorphite, which have been called calamine historically (see: calamine (mineral)). When mixed with eugenol, the mixture is called zinc oxide eugenol and has restorative and prosthodontic applications in dentistry.

Zinc peroxide, ZnO2 .½ H2O, is a white to yellow powder that is used in antiseptic ointments.

Chemical and Biosensor applications

Zinc oxide (ZnO) has received considerable attention because of its unique optical, semiconducting, piezoelectric, and magnetic properties. ZnO nanostructures exhibit interesting properties including high catalytic efficiency and strong adsorption ability. Recently, the interest has been focused toward the application of ZnO in biosensing because of its high isoelectric , biocompatibility, and fast electron transfer kinetics. Such features advocate the use of this material as a biomimic membrane to immobilize and modify biomolecules [3]

As a food additive

Zinc oxide is added to many breakfast cereals, as a source of zinc; a necessary nutrient. (Other cereals may contain zinc sulfate, for the same purpose.) Some prepackaged foods also include trace amounts.

As a pigment

Zinc white is used as a pigment in paints and is more opaque than lithopone, but less opaque than titanium dioxide. It is also used in coatings for paper. Chinese white is a special grade of zinc white used in artists' pigments. Because it absorbs both UVA and UVB rays of ultraviolet light, zinc oxide can be used in ointments, creams, and lotions to protect against sunburn and other damage to the skin caused by ultraviolet light (see sunscreen). It is the broadest spectrum UVA and UVB absorber that is approved for use as a sunscreen by the FDA, and is completely photostable. It is also a main ingredient of mineral makeup.

Rubber manufacture

Zinc oxide and stearic acid are ingredients in the commercial manufacture of rubber goods. A mixture of these two compounds allows a quicker and more controllable rubber cure. Zinc oxide can also be used as a filler in some rubber mixtures.

Electronic materials

ZnO layers are mainly deposited by sputter deposition and chemical vapor deposition (CVD). The latter method allows the growth of a rough layer, which can diffuse the incoming light by scattering, increasing the efficiency of solar cells.

ZnO has been observed to act as a chemical reagent for Friedel-Craft Acylation Reaction.

Use in semiconductors

ZnO is a semiconductor with a direct bandgap energy of 3.37 eV at room temperature. The most common applications are in laser diodes and light emitting diodes (LEDs) since it has an exciton and biexciton energies of 60 meV and 15 meV, respectively. It is expected that this exciton properties of ZnO will be improved further by epitaxy.

Most ZnO has n-type character, even in the absence of intentional doping. Native defects such as oxygen vacancies or zinc interstitials are often assumed to be the origin of this, but the subject remains controversial[4]. An alternative explanation has been proposed, based on theoretical calculations, that unintentional substitutional hydrogen impurities are responsible[5].

n-type doped films are often used in thin film technology, where zinc oxide serves as a TCO (transparent conducting oxide). n-type doping is possible by introduction of aluminium, indium, or excess zinc[6]. p-type doping is difficult and is currently an active area of research, with arsenic as the leading candidate dopant[7]. Thin-film solar cells, LCD and flat panel displays are typical applications of this material. Appropriately doped ZnO may be transparent and conductive, and can therefore be used as a transparent electrode. Indium tin oxide (ITO) is another transparent conducting oxide often used in microelectronics.

Zinc oxide nanorod sensor

Zinc oxide nanorod sensors or ZnO nanorod sensors are zinc oxide nanowire based nanosensors developed to detect the presence of hydrogen particles at ambient temperatures[8][9].

Spintronics

ZnO has also been considered for spintronics applications because of theoretical predictions of room temperature ferromagnetism. Unsubstantiated reports of ferromagnetism have been made, but presence of dilute magnetic semiconductors remains a large unanswered question in physics.

Piezoelectricity

The piezoelectricity in textile fibers coated in ZnO have been shown capable of "self-powering nanosystems" with everyday mechanical stress generated by wind or body movements.[10][11]

In 2008 the Center for Nanostructure Characterization at the Georgia Institute of Technology reported producing an electricity generating device (called flexible charge pump generator) delivering alternating current by stretching and releasing zinc oxide wires. This mini-generator creates an oscillating voltage up to 45 millivolts, converting close to seven percent of the applied mechanical energy into electricity. Researchers used wires with lengths of 200-300 microns and diameters of three to five microns, but the device could be scaled down to nanometer size. [12]

Pyroelectric coefficients

- Primary pyroelectric coefficient: -6.8 µC/m²·K

- Secondary pyroelectric coefficient: -2.5 µC/m²·K

- Total pyroelectric coefficient: -9.4 µC/m²·K

Safety

As a food additive, Zinc oxide is on FDA's Generally recognized as safe, or GRAS, substances[13].

Zinc oxide itself is non-toxic, however it is hazardous to breathe zinc oxide fumes. Fumes of zinc oxide are generated when zinc or zinc alloys are melted and oxidized at high temperature. This occurs while melting brass, because the melting point of brass is close to the boiling point of zinc.[14] Exposure to zinc oxide in the air, which also occurs while welding galvanized (zinc plated) steel, can result in a nervous malady called metal fume fever.[15] For this reason, typically galvanized steel is not welded, or the zinc is removed first.

See also

References

- ↑ http://www.intox.org/databank/documents/chemical/zincoxd/ukpid87.htm

- ↑ Caruso TJ, Prober CG, Gwaltney JM (2007). "Treatment of naturally acquired common colds with zinc: a structured review". Clin. Infect. Dis. 45 (5): 569–74. doi:. PMID 17682990.

- ↑ Kumar, S. Ashok; Chen, Shen-Ming (2008-01). "Nanostructured Zinc Oxide Particles in Chemically Modified Electrodes for Biosensor Applications". Analytical Letters 41 (2): 141–58. doi:.

- ↑ Look, D.C.; Hemsky, J.W.; Sizelove, J.R. (1999). "Residual Native Shallow Donor in ZnO". Physical Review Letters 82 (12): 2552–2555. doi:.

- ↑ Janotti, A.; Van De Walle, C.G. (2007). "Hydrogen multicentre bonds". Nat Mater 6 (1): 44–7. doi:. http://www.ncbi.nlm.nih.gov/entrez/query.fcgi?cmd=Retrieve&db=PubMed&list_uids=17143265&dopt=Citation. Retrieved on 2007-10-26.

- ↑ Hirschwald, W.H. (1985). "Zinc oxide: an outstanding example of a binary compound semiconductor". Accounts of Chemical Research 18 (8): 228–234. doi:. http://pubs.acs.org/cgi-bin/abstract.cgi/achre4/1985/18/i08/f-pdf/f_ar00116a001.pdf?sessid=6006l3. Retrieved on 2007-10-26.

- ↑ Braunstein, G.; Muraviev, A.; Saxena, H.; Dhere, N.; Richter, V.; Kalish, R. (2005). "p type doping of zinc oxide by arsenic ion implantation". Applied Physics Letters 87: 192103. doi:. http://link.aip.org/link/?APPLAB/87/192103/1. Retrieved on 2007-10-26.

- ↑ Highly stable and reliable lightweight hydrogen sensors for fuel cells

- ↑ GaN-based and ZnO nanorod sensors for wireless hydrogen leak detection

- ↑ Keim, Brandon (February 13, 2008). "Piezoelectric Nanowires Turn Fabric Into Power Source", Wired News, CondéNet. Retrieved on 2008-02-13.

- ↑ Yong Qin, Xudong Wang & Zhong Lin Wang (October 10, 2007). "Letter/abstract: Microfibre–nanowire hybrid structure for energy scavenging". Nature (Nature Publishing Group) 451: 809–813. doi:. http://www.nature.com/nature/journal/v451/n7180/full/nature06601.html. Retrieved on 2008-02-13. cited in "Editor's summary: Nanomaterial: power dresser". Nature. Nature Publishing Group (February 14, 2008). Retrieved on 2008-02-13.

- ↑ Science Daily

- ↑ "Database of Select Committee on GRAS Substances (SCOGS) Reviews". Retrieved on 2008-03-22.

- ↑ The Safety of Zinc Casting

- ↑ Zinc and Cadmium

Bibliography

- Physics Today, volume 58, No. 8, p.33, August 2005.

- "Introduction and recovery of point defects in electron-irradiated ZnO", Tuomisto, F., Saarinen, K., Look, D.C., and Farlow, G.C., Physical Review B 72, 085206 (2005).

- "Nanostructure of ZnO fabricated via French Process and its correlation to electrical properties of semiconducting varistors", S.Mahmud, M.J.Abdullah, J.Chong, A.K.Mohamad, M.Z.Zakaria, J. Syn. React. Inorg., Met-org. and Nano-metal Chem., 36, pp155-159 (2006).

External links

- International Chemical Safety Card 0208.

- NIOSH Pocket Guide to Chemical Hazards.

- Nav Bharat Metallic Oxide Industries. (describes industrial uses of zinc oxide)

- External MSDS (Material Safety Data Sheet) on zinc oxide.