T-72

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The T-72 is a Soviet-designed main battle tank that entered production in 1971. It is a further development of the T-62[2] with some features of the T-64A (to which it was a parallel design) and has been further developed as the T-90. Chronologically, and in design terms, it belongs to the same generation of tanks as the US M60[3] series, German Leopard 1, and British Chieftain tank. More recently, its reputation has suffered following poor combat performance of older, export-model T-72s against modern M1 Abrams and Challenger 1 tanks during the Persian Gulf wars.

Contents |

Origin

The T-64 was one of the world's most advanced battle tanks when introduced, but early problems with its L60-derived engine, the roadwheels, and inaccuracy of its main gun prompted Soviet leadership to seek a low-tech alternative with similar performance, especially after the high unit costs and labour-intensive manufacture process of T-64 became obvious. The tank was too expensive to equip all Soviet tank armies, let alone Warsaw Pact (WARPAC) allies.

An "economy" tank with the old design V-46 powerplant was developed from 1967 at the Uralvagonzavod Factory located in Nizhny Tagil. Chief engineer Leonid Kartsev created "Object 172", the initial design, but the prototype, marked "Object 172M", was refined and finished by Valeri Venediktov. Field trials lasted from 1971 to 1973 and upon acceptance the Chelyabinsk Tank factory immediately ceased T-55 and T-62 production to retool for the new T-72 tank.

At least some technical documentation on the T-72 is known to have been passed to the CIA by the Polish Colonel Ryszard Kuklinski between 1971 and 1982.

Production history

The T-72 was the most common tank used by the Soviet Army from the 1970s to the collapse of the Soviet Union. It was also exported to other Warsaw Pact countries, as well as Finland, India, Iran, Iraq, Syria and Yugoslavia, as well as being copied elsewhere, both with and without licenses.

Licenced versions of T-72 were made in Poland and Czechoslovakia, for WARPAC consumers. These tanks had better and more consistent quality of make but with inferior armour, lacking the resin-embedded ceramics layer inside the turret front and glacis armour, replaced with all steel. The Polish-made T-72G tanks also had thinner armour compared to Soviet Army standard (410mm for turret). Before 1990, Soviet-made T-72 export versions were similarly downgraded for non-WARPAC customers (mostly the Arab countries). Many parts and tools are not interchangeable between the Russian, Polish and Czechoslovakian versions, which caused logistical problems.

The Yugoslavs called their copy the M-84, and sold hundreds of them around the world during the 1980s. The Iraqis called theirs the Lion of Babylon (Asad Babil), though the Iraqis assembled theirs from "spare parts" sold to them by the Russians as a means of evading the UN-imposed weapons embargo. More modern derivatives include the Polish PT-91 Twardy and Russian T-90. Several countries, including Russia and Ukraine also offer modernization packages for older T-72s.

Various versions of the T-72 have been in production for decades, and the specifications for its armour have changed considerably. Original T-72 tanks had homogeneous cast steel armour incorporating spaced armour technology and were moderately well protected by the standards of the early 1970s. In 1979, the Soviets began building T-72 modification with composite armour similar to the T-64 composite armour, in the front of the turret and the front of the hull. Late in the 1980s, T-72 tanks in Soviet inventory (and many of those elsewhere in the world as well) were fitted with reactive armour tiles and extra layer of synthetic ABV shielding carpet on the outside, which also served as an anti-slipping foot restraint.

Laser rangefinders appear in T-72 tanks since 1978, earlier examples were equipped with parallax optical rangefinders, which could not be used for distances under 1,000 metres (1,100 yd). Some export versions of T-72 lacked the laser rangefinder until 1985 or only the squadron and platoon commander tanks (version K) received them. After 1985, all newly made T-72 came with reactive armour as standard, more powerful 840 bhp (630 kW) V-84 engine and an upgraded design main gun, which can fire guided anti-tank missiles from the barrel. With these developments the T-72 eventually became almost as powerful as the more expensive T-80 tank, but few of these late variants reached the economically ailing WARPAC allies and foreign customers before the Soviet bloc fell apart in 1990.

Since 2000, export vehicles have been offered with thermal imaging night-vision gear of French manufacture as well (though it may be more likely that they might simply use the locally manufactured 'Buran-Catherine' system, which incorporates a French thermal imager). Depleted uranium armour-piercing ammunition for the 125 mm gun has been manufactured in Russia in the form of the BM-32 projectile since around 1978, though it has never been deployed, and is less penetrating than the later tungsten BM-42 and the newer BM-42M, which compares in penetrating ability to the German DM-53.

The T-72 is common around the world in the armies of many potential enemies of the U.S. and other Western nations. Many Western analysts regard this as worrisome because, at least theoretically, its 125 mm 2A46 main gun is capable of destroying any modern main battle tank in the world today, including the M1 Abrams. On the other hand, on the three occasions when Soviet clients using T-72s have met Western armies that possessed modern main battle tanks —Lebanon in 1982 (against the Israeli Merkava), Iraq in 1991 (against the U.S. M1 Abrams and the British Challenger 1), and again Iraq in 2003— the T-72 did not show its alleged abilities. After clashes in Lebanon in 1982, both the Israelis and the Syrians claimed their main tank's superiority. In both the Gulf War and the Iraq War, the Iraqi tank units were heavily defeated, although this might have more to do with poor Iraqi crew training and full Allied air supremacy than with any deficiencies of the T-72 itself. Furthermore, while facing the most modern Western tanks, the versions the Iraqi army fielded were out of date at the time. The Iraqi T-72s were less-capable export versions that had not been significantly upgraded, and were firing inferior ammunition (often with steel penetrators and half-charges of propellant).

Models

Main models of the T-72, built in the Soviet Union and Russia. Command tanks have K added to their designation for komandirskiy, ‘command’, for example T-72K is the command version of the basic T-72. Versions with reactive armour have V added, for vzryvnoy, ‘explosive’.

- T-72 Ural (1973)[4] – Original version, armed with 125 mm smoothbore tank gun and optical coincidence rangefinder.[5][6][7]

- T-72A (1979)[4] – Added laser rangefinder and electronic fire control, turret front and top being heavily reinforced with composite armour (nicknamed Dolly Parton by US intelligence), provisions for mounting reactive armor, smoke grenade launchers, flipper armour mount on front mudguards, internal changes.[7][1][6][4][7]

- T-72M – Export version, similar to T-72A but with thinner armour and downgraded weapon systems. Also built in Poland and former Czechoslovakia[8][7]

- T-72B (1985)[4] – New main gun, stabilizer, sights, and fire control, capable of firing 9M119 Svir guided missile, Super Dolly Parton armour including 20 mm (0.8 in) of appliqué armour in the front of hull, improved 840-hp (626 kW) engine.

- T-90 (1995) – Modernization of the T-72, incorporating technical features of the heavier, more complex T-80. It was first called T-72BU but after the poor performance of the T-72 in Chechnya, Kuwait, and Iraq, it was decided to rename it to improve its chances on the export market.[6]

Variants

The T-72 hull has been used as the basis for other heavy vehicle designs, including the following:

- BMPT – Heavy convoy and close tank support vehicle.

- TOS-1 – Napalm rocket launcher, with 30-tube launcher in place of the turret.[7]

- BREM-1 (Bronirovannaya Remonto-Evakuatsionna Mashina) – Armoured recovery vehicle with a 12-tonne crane, 25-tonne winch, dozer blade, towing equipment, and tools.[7]

- IMR-2 (Inzhenernaya Mashina Razgrashdeniya) – Combat engineering vehicle with an 11-tonne telescoping crane and pincers, configurable dozer blade/plough, and mine-clearing system.

- MTU-72 (Tankovyy Mostoukladchik) – Armoured bridge layer, capable of laying a 50 t (55 short tons) capacity bridge spanning 18 m (60 ft) in three minutes.[7]

Design characteristics

The T-72 exhibits many design features shared with other tank designs of Soviet origin. Some of these are viewed as deficiencies in a straight comparison to NATO tanks, but most are a product of the way these tanks were envisioned to be employed, based on the Soviets' practical experiences in World War II.

Weight

The T-72 is extremely lightweight, at forty-one tonnes, and very small compared to Western main battle tanks. Some of the roads and bridges in former Warsaw Pact countries were designed such that T-72s can travel along in formation, but NATO tanks could not pass at all, or just one-by-one, significantly reducing their mobility. The basic T-72 is relatively underpowered, with a 780 hp (580 kW) supercharged version of the basic 500 hp (370 kW) V-12 diesel engine block originally designed for the WWII T-34. The tracks run on large-diameter road wheels, which allows for easy identification of T-72 and descendants (the T-64/80 family has relatively small road wheels). Ride comfort is reported as poor compared to Western tanks equipped with hydrodynamic suspension.

The T-72 is designed to cross rivers up to 5 m (16 ft) deep submerged using a small diameter snorkel assembled on-site. Because the hull is not water-tight, the crew is individually supplied with a simplistic rebreather chest-pack apparatus for survival. If the engine stops underwater, it must be restarted within six seconds, or the T-72's engine compartment becomes flooded due to pressure loss. The snorkelling procedure is considered dangerous but is important for maintaining operational mobility.

Nuclear, biological, and chemical protection

The T-72 has a comprehensive nuclear, biological, and chemical (NBC) protection system. The inside of both hull and turret is lined with a synthetic fabric made of boron compound, meant to reduce the penetrating radiation from neutron bomb explosions. The crew is supplied clean air via a complicated air filter system. A slight over-pressure prevents entry of contamination via bearings and joints. Use of an autoloader for the main gun allows for more efficient forced smoke removal compared to traditional manually-loaded ("pig-loader") tank guns, so NBC isolation of the fighting compartment can, in theory, be maintained indefinitely. Exported T-72s do not have the internal lining that is standard on Russian T-72s, which consists of a layer of synthetic material, containing lead, that provides some degree of protection against the effects of neutron radiation and electromagnetic pulses.

Interior

Like all Soviet-legacy tanks, the T-72's design has traded off interior space in return for a very small silhouette and efficient use of armour, to the point of replacing the fourth crewman with a mechanical loader. The smaller complement increases the crew's mental and physical exhaustion (although in service, the tank crew is supplemented by a mechanic who travels with the military support organization). The small interior also demands the use of shorter crewmen, with the maximum height set at 1.6 m (5 ft 4 in) in the Soviet Army (similar height restrictions exist in other Soviet-era armored vehicles). [9] The basic T-72 design has extremely small periscope viewports, even by the constrained standards of battle tanks and the driver's field of vision is significantly reduced when his hatch is closed. The steering system is a traditional dual-tiller layout instead of the steering wheel or steering yoke common in modern Western tanks. This set-up requires the near-constant use of both hands, which complicates employment of the seven speed manual gearbox.

Armour

Armour protection of the T-72 was strengthened with each succeeding generation. The original T-72 turret is made from conventional cast armour. It is believed the maximum thickness is 280 mm (11 in), the nose is about 80 mm (3 in) and the glacis of the new laminated armour is 200 mm (8 in) thick, which when inclined gives about 500–600 mm (20–24 in) thickness along the line of sight. Late model T-72s feature composite armour protection.

The T-72M (export version of the Soviet T-72A) featured a different armour protection compared to the T-72A: it had a different composite insert in the turret cavity which granted it less protection against HEAT and armour-piercing (AP) munitions. The modernised T-72M1 featured an additional 16 mm (0.63 in) of armour on the glacis plate, which produced an increase of 32 mm (1.3 in) horizontally against both HEAT and AP. It also featured a newer composite armour in the turret with pelletised filler agent.

Several T-72 models featured explosive reactive armour (ERA), which increased protection primarily against HEAT type weapons. Certain late-model T-72 tanks featured heavy ERA to help defeat modern HEAT and AP against which they were insufficiently protected.

Late model T-72s, such as the T-72B, featured improved turret armour, visibly bulging the turret front—nicknamed "Dolly Parton" armour by Western intelligence. The glacis was also fitted with 20 mm (0.8 in) of appliqué armour. The late production versions of the T-72B/B1 and T-72A variants also featured an anti-radiation layer on the hull roof.

Early model T-72 did not feature side skirts, instead the original base model featured gill or flipper-type armour panels on either side of the forward part of the hull. When the T-72A was introduced in 1979 it was the first model to feature the plastic side skirts covering the upper part of the suspension, with separate panels protecting the side of the fuel and stowage panniers.

In contrast to recent Western tanks, the T-72 stores ammunition in the crew compartment, including in the turret. This means if the main compartment is penetrated, ammunition cook-off can occur, which is likely to kill the crew and blast the turret high into the air. American tank crews who faced Iraqi T-72s during the two Persian Gulf Wars referred to the tank as the "jack-in-the-box".

The July 1997 issue of Jane's International Defence Review confirmed that after the collapse of USSR, US and German analysts had a chance to examine Soviet made T-72 tanks equipped with Kontakt-5 ERA, and they proved impenetrable to most modern US and German tank projectiles; this sparked the development of more modern Western tank ammunition, such as the M829A2 and M829A3. Russian tank designers responded with newer types of Heavy Reactive Armour, including Relikt and Kaktus.

Gun

The T-72 is equipped with the 125 mm 2A46 series main gun, which was significantly larger than the standard 105 mm gun found in contemporary Western MBTs, and still slightly larger than the 120 mm/L44 found in many modern Western MBTs. As is typical of Soviet tanks, the gun is capable of firing anti-tank guided missiles, as well as standard main gun ammunition, including HEAT and APFDS rounds.

The main gun of the T-72 has a mean error of one metre (39 in) at a range of 1,800 m (2,000 yd), which is considered substandard today. Its maximum firing distance is 9,100 m (10,000 yd), due to limited positive elevation. The limit of aimed fire is 4,000 m (4,400 yd) (with the gun-launched anti-tank guided missile, which is rarely used outside the former USSR). The T-72's main gun is fitted with an integral pressure reserve drum, which assists in rapid smoke evacuation from the bore after firing. The 125 millimetre gun barrel is certified strong enough to ram the tank through forty centimetres of iron-reinforced brick wall, though doing so will negatively affect the gun's accuracy when subsequently fired. Rumours in NATO armies of the late Cold War claimed that the tremendous recoil of the huge 125 mm gun could damage the fully mechanical transmission of the T-72. The tank commander reputedly had to order firing by repeating his command, when the T-72 is on the move: "Fire! Fire!" The first shout supposedly allowed the driver to disengage the clutch to prevent wrecking the transmission when the gunner fired the cannon on the second order. In reality, this still-common tactic substantively improves the tank's firing accuracy and has nothing to do with recoil or mechanical damage to anything.

The vast majority of T-72s do not have FLIR thermal imaging sights, though all T-72s (even those exported to the Third World) possess the characteristic (and inferior) 'Luna' IR illuminator. Thermal imaging sights are extremely expensive, and the new Russian FLIR system, the 'Buran-Catherine Thermal Imaging Suite' was only introduced recently on the T-80UM tank. Most T-72s found outside the former Soviet Union do not have laser rangefinders. T-72 built for export have a downgraded fire-control system and automatic loader.

Autoloader

The T-72's autoloader design is not based on the faster, but more complicated autoloader in the USSR's domestic-use-only T-64 tank series (the T-72's is horizontally auto-fed, the T-64's uses vertical actuators). These systems are fast but prone to malfunctions if not maintained properly. Even if properly maintained they can be relatively unreliable. It takes between 6.5 and 15 seconds to load a new shell into the main gun, depending on the current position of the autoloader carousel. The autoloader must crank the gun up three degrees above the horizontal in order to depress the breech end of the gun and line it up with the new shell. While autoloading, the gunner can still aim because he has a vertically independent sight. With a laser rangefinder and a ballistic computer, final aiming takes at least another three to five seconds, but aiming is pipelined into the last steps of auto-loading so it proceeds concurrently. Refilling the autoloader with new shells is a real maintenance burden and requires great attention to maintain the specified sequence, but it should be noted that the average rate of fire for this type of carousel automatic loader is quoted to be 8 rounds per minute. Trained T-72 crews don't find reloading much worse than loading other tank types; the separated cartridges are easier to handle.

Deployment

A significant characteristic of all Soviet and Russian tanks since the Second World War is their relatively limited range of main gun elevation and depression. The T-72's low profile requires a correspondingly low turret roof, which blocks upward travel of the gun breech. As a consequence, the main gun can be depressed only a few degrees, making it difficult to employ the T-72 stop in a well-protected hull-down position, with the bulk of the tank parked just behind the crest of a ridge, leaving only the gun visible.

Western tanks have considerably more elevation range. However, the T-72 is fitted with an integral hydraulic bulldozer blade on the underside of the frontal glacis plate, which enables the T-72 to excavate and construct a defensive position that minimizes the need for gun depression.

Recent CIS export designs, intended to compete with Western tanks on the open market, have placed more emphasis on defence and crew survivability. The Ukrainian T-84 Oplot, T-84-120 Yatagan, and Russian Black Eagle appear to have armoured blow-out ammunition compartments.

Combat history

- 1979–1989 Soviet war in Afghanistan (employed by the Soviet Union)

- 1980–1988 Iran–Iraq War (Iraq)

- 1982 Lebanon (Syria)

- 1983– Sri Lankan Civil War (India)

- 1988–1994 Nagorno-Karabakh War (Armenia and Azerbaijan)

- 1988–1993 Georgian Civil War

- 1991–1992 War in South Ossetia

- 1992–1993 War in Abkhazia

- 1990–1991 First Persian Gulf War (Iraq)

- 1991–2001 Yugoslav Wars (Yugoslavia)

- 1991 Ten-Day War (Yugoslavia)

- 1991–1995 Croatian War of Independence (Yugoslavia, Krajina Serbs, Croatia and Republika Srpska)

- 1996–1999 Kosovo War (Yugoslavia)

- 1999–2001 Insurgency in the Preševo Valley (Yugoslavia)

- 2001 Macedonia (Macedonia)

- 1994–1996 First Chechen War (Russia)

- 1999– Second Chechen War (Russia)

- 2003 Invasion of Iraq (Iraq)

- 2003– Second Gulf War (Iraq)

- 2008 War in South Ossetia (Russia, South Ossetia, and Georgia)

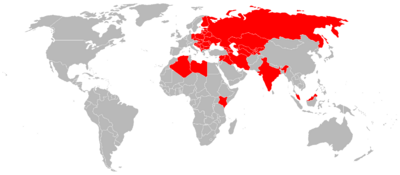

The T-72 worldwide

The T-72 has been used by over 40 countries worldwide. It has been built under licence and further developed in several countries, including the following:

- Safir-74 , Iran

- Lion of Babylon tank, Iraq

- M-84, Yugoslavia

- M-95 Degman, Croatia

- M-2001, Serbia

- PT-91 Twardy, Poland

- Tank EX, India

- TR-125, Romania

See also

- Comparable AFVs: Chieftain tank, Leopard 1, M60 Main Battle Tank

- Related lists: List of tanks, List of Soviet tanks

- 125mm Smoothbore Rounds

Gallery

Notes

- ↑ 1.0 1.1 "Gary's Combat Vehicle Reference Guide"

- ↑ "Czolgi Swiata" (World's Tanks or Tanks Of The World) magazine issue 19

- ↑ Hunnicutt, p. 6 & 408

- ↑ 4.0 4.1 4.2 4.3 "War Technology"

- ↑ "Czolgi Swiata" (World's Tanks or Tanks Of The World) magazine issue 20

- ↑ 6.0 6.1 6.2 T-72 [ZSRR]: Strona 2 - Pancerni.net

- ↑ 7.0 7.1 7.2 7.3 7.4 7.5 7.6 "JED The Military Equipment Directory"

- ↑ T-72 [ZSRR]: Strona 3 - Pancerni.net

- ↑ Perret 1987:121

References

- Sewell, Stephen ‘Cookie’ (1998). "“Why Three Tanks?”". Archived from the original on 2007-06-28. in Armor vol. 108, no. 4, p. 21. Fort Knox, KY: US Army Armor Center. ISSN 0004-2420. (PDF format)

- Foss, Christopher F. Jane's Armour and Artillery 2005-2006. ISBN 978-0-7106-2686-8.

- Leizin, Uri (2004) "Two myths of one battle: Syrian T-72's in 1982 Lebanon war"(in Russian)

- Zaloga, Steven J (1993) T-72 Main Battle Tank 1974-93, Osprey Publishing ISBN 1-85532-338-9.

- Ustyantsev, Sergej Viktorovich; Kolmakov Dmitrij Gennadevich "Boyeviye mashiny Uralvagonzavoda. Tank T-72"

- Karpenko, A.V. (1996) "Obozreniye Bronetankovoj Tekhniki (1905-1995 gg.)" Nevskij Bastion

- Perret, Bryan (1987). Soviet Armour Since 1945. London: Blandford Press. ISBN 0-7137-1735-1.

- Hunnicutt, R. P. "Patton: A History of the American Main Battle Tank." 1984, Presidio Press. ISBN 0-89141-230-1.

External links

- Uralvagonzavod, manufacturer's English-language home page (Russian)

- Vasiliy Fofanov's Modern Russian Armour Page

- T-72 variants (German)

- NiiStali website

- Detailed description of the T-72/90 at www.kampfpanzer.de (English) (German)

- "??????". Retrieved on 2008-06-15. "Kalejdoskop" (Russian language)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||