Sodium chloride

| Sodium chloride | |

|---|---|

|

|

|

|

| IUPAC name | Sodium chloride |

| Other names | Common salt; halite; table salt |

| Identifiers | |

| CAS number | 7647-14-5 |

| RTECS number | VZ4725000 |

| ChemSpider ID | |

| Properties | |

| Molecular formula | NaCl |

| Molar mass | 58.44277 g/mol |

| Appearance | White or colorless crystals or powder |

| Odor | Odourless |

| Density | 2.16 g/cm³, solid |

| Melting point |

801 °C (1074 K) |

| Boiling point |

1465 °C (1738 K) |

| Solubility in water | 35.9 g/100 mL (25 °C) |

| Structure | |

| Crystal structure | Face centered cubic |

| Coordination geometry |

Octahedral |

| Hazards | |

| Main hazards | Might sting eyes, prolonged exposure to flame and air liberates strong acid |

| NFPA 704 |

0

1

1

|

| R-phrases | R36 |

| S-phrases | S15,S25,S47 |

| Flash point | Non-flammable |

| LD50 | 3000–8000 mg/kg (oral in rats, mice, rabbits)[1] |

| Related compounds | |

| Other anions | NaF, NaBr, NaI |

| Other cations | LiCl, KCl, RbCl, CsCl, MgCl2, CaCl2 |

| Related salts | Sodium acetate |

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C, 100 kPa) Infobox references |

|

Sodium chloride, also known as common salt, table salt, or halite, is a chemical compound with the formula NaCl. Sodium chloride is the salt most responsible for the salinity of the ocean and of the extracellular fluid of many multicellular organisms. As the major ingredient in edible salt, it is commonly used as a condiment and food preservative.

Contents |

Production and use

Salt is currently mass-produced by evaporation of seawater or brine from other sources, such as brine wells and salt lakes, and by mining rock salt, called halite. In 2002, world production was estimated at 210 million metric tonnes, the top five producers being the United States (40.3 million tonnes), China (32.9), Germany (17.7), India (14.5), and Canada (12.3).[2]

As well as the familiar uses of salt in cooking, salt is used in many applications, from manufacturing pulp and paper, to setting dyes in textiles and fabric, to producing soaps, detergents, and other bath products. It is the major source of industrial chlorine and sodium hydroxide, and used in almost every industry.

In cold countries, large quantities of rock salt are used to help clear highways of ice during winter, although "Road Salt" loses its melting ability at temperatures below -15°C to -20°C (5°F to -4°F). Sodium chloride is sometimes used as a cheap and safe desiccant due to its hygroscopic properties, making salting an effective method of food preservation historically. Even though more effective desiccants are available, few are safe for humans to ingest.

| Solubility of NaCl in various solvents (g NaCl / 100 g of solvent at 25 °C) |

|

|---|---|

| H2O | 36 |

| Liquid ammonia | 3.02 |

| Methanol | 1.4 |

| Sulfolane | 0.005 |

| Formic acid | 5.2 |

| Acetone | 0.000042 |

| Formamide | 9.4 |

| Acetonitrile | 0.0003 |

| Dimethylformamide | 0.04 |

| Reference: Burgess, J. Metal Ions in Solution (Ellis Horwood, New York, 1978) ISBN 0-85312-027-7 |

|

Synthetic uses

Sodium chloride is also the raw material used to produce chlorine which itself is required for the production of many modern materials including PVC and pesticides. Industrially, elemental chlorine is usually produced by the electrolysis of sodium chloride dissolved in water. Along with chlorine, this chloralkali process yields hydrogen gas and sodium hydroxide, according to the chemical equation

- 2NaCl + 2H2O → Cl2 + H2 + 2NaOH

Sodium metal is produced commercially through the electrolysis of liquid sodium chloride. This is now done in a Down's cell in which sodium chloride is mixed with calcium chloride to lower the melting point below 700 °C. As calcium is more electropositive than sodium, no calcium will be formed at the cathode. This method is less expensive than the previous method of electrolyzing sodium hydroxide.

Sodium chloride is used in other chemical processes for the large-scale production of compounds containing sodium or chlorine. In the Solvay process, sodium chloride is used for producing sodium carbonate and calcium chloride. In the Mannheim process and in the Hargreaves process, it is used for the production of sodium sulfate and hydrochloric acid.

Biological uses

Many microorganisms cannot live in an overly salty environment: water is drawn out of their cells by osmosis. For this reason salt is used to preserve some foods, such as smoked bacon or fish and can also be used to detach leeches that have attached themselves to feed. It has also been used to disinfect wounds.

Optical uses

Pure NaCl crystal is an optical compound with a wide transmission range from 200nm to 20um. It was often used in the infrared spectrum range and it is still used sometimes.

NaCl crystal is soft, hygroscopic and cheap. This limits its application to protected environment or for short term uses ( prototyping ). Exposed to free air NaCl optics will "rot".

Today tougher crystals like ZnSe are used instead of NaCl (for the IR spectral range).

Optical data

- Transmission Range: 200nm to 20μm

- Transmitivity: 92% (from 400nm to 13μm)

- Refractive Index: 1.494 @ 10μm

- Reflection Loss: 7.5% @ 10μm (2 surfaces)

- dN/dT: -36.2 x 10-6/°C @ 0.7μm

Household uses

Since at least medieval times, people have used salt as a cleansing agent rubbed on household surfaces. It is also used in many brands of shampoo.

Biological functions

In humans, a high-salt intake has long been known to generally raise blood pressure, especially in certain individuals. More recently, it was demonstrated to attenuate nitric oxide production. Nitric oxide (NO) contributes to vessel homeostasis by inhibiting vascular smooth muscle contraction and growth, platelet aggregation, and leukocyte adhesion to the endothelium.[3][4]

Crystal structure

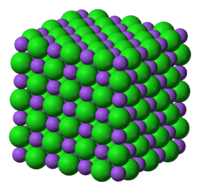

Sodium chloride forms crystals with cubic symmetry. In these, the larger chloride ions, shown to the right as green spheres, are arranged in a cubic close-packing, while the smaller sodium ions, shown to the right as silver spheres, fill all the cubic gaps between them.

Each ion is surrounded by six ions of the other kind. This same basic structure is found in many other minerals, and is known as the halite structure. This arrangement is known as cubic close packed (ccp). It can be represented as two interpenetrating face-centered cubic (fcc) lattices, or one fca lattic with a two atom basis. It is most commonly known as the rocksalt crystal structure.

It is held together with an ionic bond and electrostatic forces.

Road salt

While salt was once a scarce commodity in history, industrialized production has now made salt plentiful. About 51% of world output is now used by cold countries to de-ice roads in winter, both in grit bins and spread by winter service vehicles. This works because salt and water form a eutectic mixture. Adding salt to water will lower the freezing temperature of the water, depending on the concentration. The salinity (S) of water is measured as grams salt per kilogram (1000g) water, and the freezing temperatures are as follows.

| S(g/kg) | 0 | 10 | 20 | 24.7 | 30 | 35 |

| T(freezing) (C) | 0 | -0.5 | -1.08 | -1.33 | -1.63 | -1.91 |

Additives

Table salt sold for consumption today is not pure sodium chloride. In 1911 magnesium carbonate was first added to salt to make it flow more freely.[5] In 1924 trace amounts of iodine in form of sodium iodide, potassium iodide or potassium iodate were first added, to reduce the incidence of simple goiter.[6]

Salt for de-icing in the UK typically contains sodium hexacyanoferrate (II) at less than 100ppm as an anti-caking agent. In recent years this additive has also been used in table salt.

Common chemicals

Chemicals used in de-icing salts are mostly found to be sodium chloride (NaCl) or calcium chloride (CaCl2). Both are similar and are effective in de-icing roads. When these chemicals are produced, they are mined/made, crushed to fine granules, then treated with an anti-caking agent. Adding salt lowers the freezing point of the water, which allows the liquid to be stable at lower temperatures and allows the ice to melt. Alternative de-icing chemicals have also been used. Chemicals such as calcium magnesium acetate and potassium formate are being produced. These chemicals have few of the negative chemical effects on the environment commonly associated with NaCl and CaCl2.[7][8]

See also

- Biosalinity

- Black salt

- Halite, the mineral form of sodium chloride

- Salinity

- Soap

- Salting the earth

References

- ↑ Martel, B.; Cassidy, K. (2004). Chemical Risk Analysis: A Practical Handbook. Butterworth–Heinemann. pp. 369. ISBN 1903996651.

- ↑ Susan R. Feldman. Sodium chloride. Kirk-Othmer Encyclopedia of Chemical Technology. John Wiley & Sons, Inc. Published online 2005. doi:10.1002/0471238961.1915040902051820.a01.pub2

- ↑ [http://content.karger.com/ProdukteDB/produkte.asp?Aktion=ShowPDF&ProduktNr=223997&Ausgabe=228460&ArtikelNr=63555 Relationship between Salt Intake, Nitric Oxide and Asymmetric Dimethylarginine and Its Relevance to Patients with End-Stage]

- ↑ Dietary sodium and cardiovascular and renal disease risk factors: dark horse or phantom entry?

- ↑ "Morton Salt FAQ".

- ↑ Markel H (1987). ""When it rains it pours": endemic goiter, iodized salt, and David Murray Cowie, MD". American journal of public health 77 (2): 219–29. PMID 3541654. http://www.pubmedcentral.nih.gov/articlerender.fcgi?artid=1646845.

- ↑ Finnish Environment Institute (1/9/2007). "Migration of alternative de-icing chemicals in aquifers (MIDAS)". Press release.

- ↑ Finnish Environment Institute (2/10/2004). "Alternative de-icer found". Press release.

External links

- The Salt Manufacturers Association website

- Salt Institute website

- Salt Archive website

- Video of rotating rock salt unit cell (divx, 378kb)

- Salt United States Geological Survey Statistics and Information

- US Road Management website

- Salt Intake in Cold Weather

- Oxford MSDS