Parchment

Parchment is a thin material made from calfskin, sheepskin or goatskin. Its most common use is as the pages of a book, codex or manuscript. It is distinct from leather in that parchment is not tanned, but stretched, scraped, and dried under tension, creating a stiff white, yellowish or translucent animal skin. The finer qualities of parchment are called vellum. It is very reactive with changes in relative humidity and is not waterproof.

Plant-based parchment or parchment paper is used in baking and other applications as a substitute for parchment.

Contents[hide] |

History

According to the Roman Varro, Pliny's Natural History records (xiii.21), parchment was invented under the patronage of Eumenes of Pergamum,[1] as a substitute for papyrus, which was temporarily not being exported from Alexandria, its only source.

Herodotus mentions writing on skins as common in his time, the 5th century BC; and in his Histories (v.58) he states that the Ionians of Asia Minor had been accustomed to give the name of skins — diphtherai — to books; this word was adapted by Hellenized Jews to describe scrolls [1]. Parchment (pergamenum in Latin), however, is named after the city where it was perfected. In the 2nd century B.C. a great library was set up in Pergamon that rivaled the famous Library of Alexandria. As prices rose for papyrus and the reed used for making it was overharvested towards local extinction in the two nomes of the Nile delta that produced it, Pergamon adapted by increasing use of parchment.

Writing on prepared animal skins had a long history, however. Some Egyptian Fourth Dynasty texts were written on parchment. Though the Assyrians and the Babylonians impressed their cuneiform on clay tablets, they also wrote on parchment from the 6th century BC onward. Rabbinic culture equated a "book" with a parchment scroll. Early Islamic texts are also found on parchment.

One sort of parchment is vellum, a word that is used loosely to mean parchment, and especially to mean fine parchment, but more strictly refers to parchment made from calf skin (although goat skin can be as fine in quality). The words "vellum" and "veal" come from Latin vitulus, "calf", or its diminutive vitellus. In the Middle Ages calfskin and split sheepskin were the most common materials for making parchment in England and France, while goatskin was more common in Italy. Other skins such as those from large animals such as horse and smaller animals such as squirrel and rabbit were also used. Whether uterine vellum (vellum made from aborted calf fetuses) was ever really used during the medieval period is still a matter of great controversy.

There was a short period during the introduction of printing where parchment and paper were used interchangeably: although most copies of the Gutenberg Bible are on paper, some were printed on parchment. In 1490, Johannes Trithemius preferred the older methods, because "handwriting placed on parchment will be able to endure a thousand years. But how long will printing last, which is dependent on paper? For if ...it lasts for two hundred years that is a long time." [2]

The heyday of parchment use was during the medieval period, but there has been a growing revival of its use among contemporary artists since the late 20th century. Although parchment never stopped being used (primarily for governmental documents and diplomas) it had ceased to be a primary choice for artist’s supports by the end of 15th century Renaissance. This was partly due to its expense and partly due to its unusual working properties. Parchment consists mostly of collagen. When the water in paint media touches parchment’s surface, the collagen melts slightly, forming a raised bed for the paint, a quality highly prized by some artists. Parchment is also extremely affected by its environment and changes in humidity, which can cause buckling. Some contemporary artists also prize this quality, noting that the parchment seems alive and like an active participant in making artwork. To support the needs of the revival of use by artists, a revival in the art of making individual skins is also underway. Handmade skins are usually better prepared for artists and have fewer oily spots which can cause long-term cracking of paint than mass-produced parchment. Mass-produced parchment is usually made for lamp shades, furniture, or other interior design purposes.[3]

The radiocarbon dating techniques that are used on papyrus can be applied to parchment as well. They do not date the age of the writing but the preparation of the parchment itself. However, radiocarbon dating can often be used on the inks that make up the writing, since many of them contain organic compounds such as plant leachings, soot, and wine.

Manufacture

The first step in creating parchment was to wet or soak the recently flayed skin in water to remove the blood and dung and to allow easier penetration of the dehairing liquor.[4]

In early days the liquor bath was fermented vegetable matter but by the Middle Ages a lime bath was used to soften the epidermal layer thus allowing the hair to be removed more easily. It is possible that urine was sometimes used as a lime alternative.

The liquor bath would have been in wooden or stone vats and the hides stirred with a long wooden pole to avoid getting the lime on human skin. The skins would stay in the bath for 8 or more days (longer in winter) being stirred two or three times a day.

After being rinsed the skins would be given a second lime bath but care would be taken to not leave the skins in too long or they would be weakened and not able to stand the stretching required for parchment.[4]

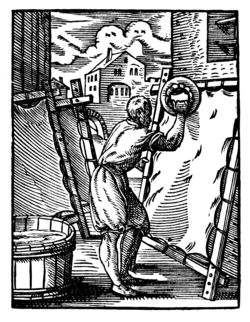

The stretching allowed the fibres to become aligned running parallel to the grain. Cords were attached and the skin was stretched on a wooden frame with both sides open so they could be scraped with a sharp, curved knife to remove the last of the hair and get the skin to the right thickness.

The skins, which were made almost entirely of collagen, would form a natural glue while drying and once taken off the frame they would keep their form.

Parchment treatments

To make the parchment more aesthetically pleasing or more suitable for the scribes, special treatments were used.

According to Reed there were a variety of these treatments. Rubbing pumice powder into the flesh side of parchment while it was still wet on the frame was used to make it smooth so inks would penetrate deep into the fibres.

Powders and pastes of calcium compounds were also used to help remove grease so the ink would not run.

To make the parchment smooth and white, thin pastes (starchgrain) of lime, flour, egg whites and milk were rubbed into the skins.

Meliora di Curci in her paper "The History and Technology of Parchment Making" notes that parchment was not always white. "Cennini, a 15th century craftsman provides recipes to tint parchment a variety of colours including purple, indigo, green, red and peach." The Early medieval Codex Argenteus and Codex Vercellensis, the Stockholm Codex Aureus and the Codex Brixianus give a range of luxuriously produced manuscripts all on purple vellum, in imitation of Byzantine examples, like the Rossano Gospels, Sinope Gospels and the Vienna Genesis, which at least at one time are believed to have been reserved for Imperial commissions.

Reuse

- Main article Palimpsest.

During the seventh through the ninth centuries, many earlier parchment manuscripts were scrubbed and scoured to be ready for rewriting, and often the earlier writing can still be read. These "recycled" parchments are called palimpsests. Later, more thorough techniques of scouring the surface irretrievably lost the earlier text.

Alternatives to Parchment

- Main article Gevil.

The way in which parchment was processed (from hide to parchment) has undergone a tremendous evolution based on time and location. Parchment and vellum are not the sole methods of preparing animal skins for writing. In the Babylonian Talmud (Bava Batra 14B) Moses writes the first Torah Scroll on the unsplit cow-hide called gevil.

- Main article paper.

In the later Middle Ages European parchment in turn was largely replaced by paper, a Chinese invention that was being manufactured in Moorish Andalusia in the eleventh century. Paper became particularly important with the advent of printing in the later fifteenth century, since the demands of printers would have outstripped the supply of animal skins for parchment.

Parchment is still the only medium used by religious Jews for Torah scrolls or Tefilin and Mezuzahs, and is produced by large companies in Israel. For those uses, only hides of kosher animals are permitted. Since there are many requirements for it being fit for the religious use, the liming is usually processed under supervision of a qualified Rabbi.[5]

In the Ancient Indian civilization, the use of parchment was extremely limited and plant-based materials such as birch bark and palm leaves, as well as paper after the 10th century were used as the common media for codexes, religious and cultural texts.

Additional uses of the term

In some universities, the word parchment is still used to refer to the certificate (scroll) presented at graduation ceremonies, even though the modern document is printed on paper or thin card; although doctoral graduands may be given the option of having their scroll written by a calligrapher on vellum. The University of Notre Dame still uses animal parchment for its diplomas.

Plant-based parchment

Vegetable (paper) parchment is made by passing a waterleaf made of pulp fibers into sulfuric acid. The sulfuric acid hydrolysises and solubilises the main natural organic polymer present in the pulp wood fibers, the cellulose. The paper web is then washed and neutralized in water, which stops the hydrolysis of the cellulose and makes a kind of cellulose coating onto the waterleaf. The final paper is dried. This coating is a natural cement, non porous that gives to the vegetable parchment paper its grease resistance which is the main feature of this paper along with its semi-translucancy. Other processes can be used to obtain grease resistant paper, such as by highly beating the fibers giving an even more translucent paper with the same grease resistance. To avoid sticking to foods, silicone and other coatings may be applied to parchment. One can obtain grease resistance by waxing the paper or by using fluorine based chemicals. When a silicone coating treatment is applied to the surface of the paper, this produces a cross-linked material with high density, stability and heat resistance and low surface tension which imparts good anti-stick or release properties. Chromium salts can also be used to impart moderate anti-stick properties. Applications include cooking and baking (cooking parchment, baking parchment).

A common use is to eliminate the need to grease baking sheets and the like, allowing very rapid turn-around of batches of cookies in a commercial bakery. It can also be folded to make moisture-proof packages in which food items are cooked or steamed en papillote.

Standard waxed grease-proof paper, known as wax paper, is a different material and can't be used for cooking as wax will melt.

Parchment Craft

Historians believe that parchment craft originated as an art form in Europe during the 15th or 16th century. Parchment craft at that time occurred principally in Catholic communities, where crafts persons created lace-like items such as devotional pictures and communion cards. The craft developed over time, with new techniques and refinements being added.

Although the invention of the printing press lead to a reduced interest in hand made cards and items, by the 18th century, people were regaining interest in detailed handwork. Parchment cards became larger in size and crafters began adding wavy borders and perforations.

In the 19th century, influenced by French romanticism, parchment crafters began adding floral themes and cherubs and hand embossing.

Until the 16th century, parchment craft was a European art form. However, missionaries and other settlers relocated to South America, taking parchment craft with them. As before, the craft appeared largely among the Catholic communities. Often, young girls receiving their First Communion received gifts of handmade parchment crafts.

In 1986, Martha Ospina, a Columbian parchment crafter moved to The Netherlands and introduced the craft to that country. In 1988, she created the Pergamano brand of parchment craft supplies and tools. Pergamano International owns the Pergamano brand and continues to supply parchment craft items internationally, as well as offering instruction and registration to people wanting to teach Pergamano parchment craft worldwide.

Parchment craft today involves various techniques, including tracing a pattern with white or colored ink, embossing to create a raised effect, stippling, perforating, coloring and cutting.

Parchment craft appears in hand made cards, as scrapbook embellishments, as bookmarks, lampshades, decorative small boxes, wall hangings and more.

See also

- Manuscript culture

- diploma

- palimpsest

- paper

- Parchment repair

- Klaf

- Gevil

- Duchsustus

Notes

- ↑ Either Eumenes I — who ruled 263–241 BC — or Eumenes II — who ruled 197–158).

- ↑ as quoted in David McKitterick, Print, Manuscript, and the Search for Order Cambridge University Press, 2003

- ↑ For examples of contemporary artists using parchment see: For an example of a contemporary parchment maker see:

- ↑ 4.0 4.1 Reed, 1975.

- ↑ Information Leaflet by Vaad Mishmereth Staam.

References

- di Curci, Meliora. (2003) The History and Technology of Parchment Making. http://www.sca.org.au/scribe/articles/parchment.htm

- Hasewint, Inden W. (2001) Tor Parchment Prepared According to Mediaeval Recipes. http://dedas.com/parchment/uk/recipe.html

- Reed, Ronald. (1975). The Nature and Making of Parchment. Leeds, England: Elmete Press

- Murray, Fiona, "Parchment Craft" in Australian Paper Crafts, No 23 2003, Pride Publishing, Rozelle NSW,pp 10-13

Further reading

- Dougherty, Raymond P., 1928." Writing upon parchment and papyrus among the Babylonians and the Assyrians," in Journal of the American Oriental Society 48, pp 109–135.

- Ryder, Michael L., 1964. Parchment: its history, manufacture and composition.

- Reed, R. 1972. Ancient Skins, Parchments, and Leathers. Seminar Press. ISBN 0-12-903550-5

External links

- Central European University, Materials and Techniques of Manuscript Production: Parchment: medieval technique

- On-line demonstration of the preparation of vellum from the BNF, Paris. Text in French, but mostly visual.

- Leaves of gold

- Meir Bar-Ilan, "Parchment"

- Lacus Curtius Website: Liber: Roman book production

- UNESCO: Parchment: production and conservation

- Inden witten Hasewint Parchment Contemporary application of the Medieval technique.

- Pergamon Perchment Web Site (Perchment invented in Pergamon)