Overhead camshaft

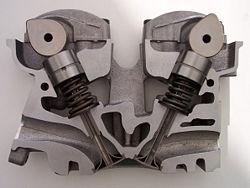

Overhead camshaft, commonly abbreviated to OHC, valvetrain configurations place the engine camshaft within the cylinder heads, above the combustion chambers, and drive the valves or lifters in a more direct manner compared to Overhead valves (OHV) and pushrods.

Compared to OHV pushrod (or I-Head) systems with the same number of valves the reciprocating components of the OHC system are fewer and have a lower total mass. Though the system that drives the cams may become more complex, most engine manufacturers easily accept that added complexity in trade for better engine performance and greater design flexibility. Another performance advantage is gained as a result of the better optimized port configurations made possible with overhead camshaft designs. With no intrusive pushrods the overhead camshaft cylinder head design can use straighter ports of more advantageous crossection and length.

The OHC system can be driven using the same methods as an OHV system, which include using a rubber/kevlar toothed timing belt, chain, or in less common cases, gears.

Many OHC engines today employ Variable Valve Timing and multiple valves to improve efficiency and power. OHC also inherently allows for greater engine speeds over comparable cam-in-block designs.

There are two overhead camshaft layouts:

- Single overhead camshaft - or SOHC

- Double overhead camshaft - or DOHC

Contents |

Single overhead camshaft

Single overhead camshaft (SOHC) is a design in which one camshaft is placed within the cylinder head. In an inline engine this means there is one camshaft in the head, while in a V engine or a horizontally-opposed engine (boxer; Flat engine) there are two camshafts: one per cylinder bank.

The SOHC design has less reciprocating mass than a comparable pushrod design. This allows for higher engine speeds, which in turn will increase power output for a given torque. The cam operates the valves directly or through a rocker arm, as opposed to overhead valve pushrod engines which have tappets, long pushrods, and rocker arms to transfer the movement of the lobes on the camshaft in the engine block to the valves in the cylinder head.

SOHC designs offer reduced complexity compared to pushrod designs when used for multi-valve heads in which each cylinder has more than two valves. An example of a SOHC design using shim and bucket valve adjustment was the engine installed in the Hillman Imp (4 cylinder, 8 valve); a small, early 1960s 2-door saloon car with a rear mounted alloy engine based on the Coventry Climax FWMA race engines. Exhaust and inlet manifolds were both on the same side of the engine block (thus not a crossflow cylinder head design). This did, however, offer excellent access to the spark plugs.

In the early 1980s Toyota and Volkswagen also used a directly actuated, SOHC parallel valve configuration with two valves for each cylinder. The Toyota system used hydraulic tappets while the Volkswagen system used bucket tappets with shims for valve lash adjustment. Of all valvetrain systems this is the least complex configuration possible.

Dual overhead camshaft

A double overhead camshaft valve train layout is characterized by two camshafts located within the cylinder head, one operating the inlet valves and one operating the exhaust valves. Some engines have more than one bank of cylinder heads (V8 and flat-four being two well-known examples) and these have more than two camshafts in total, but they remain DOHC. The term Twin Cam is imprecise, but will normally refer to DOHC engines.

Double overhead camshafts are not required in order to have multiple inlet or exhaust valves, but are necessary for more than two valves that are directly actuated (though still usually via tappets). Not all DOHC engines are multivalve engines — DOHC was common in two valve per cylinder heads for decades before multivalve heads appeared. Today, however, DOHC is synonymous with multi-valve heads since almost all DOHC engines have between three and five valves per cylinder.[1]

History

Among the early pioneers of DOHC were Isotta Fraschini's Giustino Cattaneo, Austro-Daimler's Ferdinand Porsche Stephen Tomczak (in the Prinz Heinrich), and W. O. Bentley (in 1919); Sunbeam built small numbers between 1921 and 1923.[2] The first DOHC engines were two- or four-valve per cylinder designs from companies like Fiat (1912), Peugeot Grand Prix (1913, 4 valve), Alfa Romeo GP (1914, 4 valve) and 6C (1925), Maserati Tipo 26 (1926), Bugatti Type 51 (1931), and Audi. Most Ferraris used two-valve DOHC engines as well.

When DOHC technology was introduced in mainstream vehicles, it was common for it to be heavily advertised. While used at first in limited production and sports cars, Fiat is credited as the first car company to use a belt-driven DOHC engine across their complete product line, in the mid-1960s., although Jaguar's XK6 DOHC engine was displayed in the Jaguar XK120 at the London Motor Show in 1948 and used across the whole Jaguar range through the late 1940s, 1950 and 1960s.

More than two overhead camshafts are not known to have been tried in a production engine. However MotoCzysz has designed a motorcycle engine with a triple overhead camshaft configuration with the intake ports descending through the head to two central intake ports between two outside exhaust camshafts actuating one of two exhaust valve per cylinder each. [3]

See also

- Valvetrain

- Overhead valve

- Cam-in-block

- Camless

- Helical camshaft

References

- ↑ SOHC vs DOHC Valvetrains: A Comparison

- ↑ Georgano, G. N. Cars: Early and Vintage, 1886-1930. (London: Grange-Universal, 1985).

- ↑ Motoczysz triple cam engine [1]