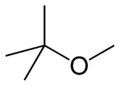

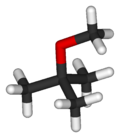

Methyl tert-butyl ether

| Methyl tert-butyl ether | |

|---|---|

|

|

| IUPAC name | 2-Methoxy-2-methylpropane |

| Other names | Methyl tertiary-butyl ether Methyl tert-butyl ether Methyl t-butyl ether MTBE tert-Butyl methyl ether tBME |

| Identifiers | |

| CAS number | 1634-04-4 |

| SMILES |

|

| Properties | |

| Molecular formula | C5H12O |

| Molar mass | 88.15 g/mol |

| Density | 0.7404 g/cm³ |

| Melting point |

-109 °C, 164 K, -164 °F |

| Boiling point |

55.2 °C, 328 K, 131 °F |

| Hazards | |

| NFPA 704 |

3

1

0

|

| Flash point | -10 °C |

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C, 100 kPa) Infobox references |

|

Methyl tert-butyl ether, also known as methyl tertiary butyl ether and MTBE, is a chemical compound with molecular formula C5H12O. MTBE is a volatile, flammable and colorless liquid that is immiscible with, yet reasonably soluble, in water. MTBE has a minty odour vaguely reminiscent of diethyl ether, leading to unpleasant taste and odour in water. MTBE is a gasoline additive, used as an oxygenate and to raise the octane number, although its use has declined in the United States in response to environmental and health concerns. It has been found to easily pollute large quantities of groundwater when gasoline with MTBE is spilled or leaked at gas stations. MTBE is also used in organic chemistry as a relatively inexpensive solvent with properties comparable to diethyl ether but with a higher boiling point and lower solubility in water. It is also used medically to dissolve gallstones.

Contents |

Production

MTBE is manufactured via the chemical reaction of methanol and isobutylene. Methanol is derived from natural gas, and isobutylene is made from crude oil or natural gas, thus MTBE, as used in motor gasoline, is a fossil fuel. In the United States, it was produced in very large quantities (more than 200,000 barrels per day in the United States in 1999) during its use as a fuel additive. Due to widespread releases of MTBE-containing gasoline from Underground Storage Tanks all over the US, various jurisdictions banned the use of MTBE and production was reduced. MTBE contamination in drinking water aquifers is a serious concern in many states (the most famous cases are Lake Tahoe and Santa Monica). By late 2006, most American gasoline retailers had ceased using MTBE as an oxygenate, and accordingly, US production had declined. Similarly, lack of growth or even decline of MTBE production has been seen in Western Europe. This is not due to environmental concerns; on the contrary, it is because the alternative ethanol-derived ether ETBE has been given more favorable tax treatment. Nevertheless, in other parts of the world, which account for about a half of 2004 production, the use of MTBE will continue and even grow.[1]

Physical properties

MTBE forms azeotropes with water (52.6 °C) and methanol (51.3 °C).

Uses

MTBE is almost exclusively used as a fuel component in motor gasoline. It is one of a group of chemicals commonly known as oxygenates because they raise the oxygen content of gasoline.

As anti-knocking agent

In the US it has been used in gasoline at low levels since 1979 to replace tetra-ethyl lead to increase its octane rating and help prevent engine knocking. Oxygen helps gasoline burn more completely, reducing tailpipe emissions from pre-1984 motor vehicles. In more modern vehicles, the emissions reduction is negligible. In one respect, the oxygen dilutes or displaces gasoline components such as aromatics (e.g., benzene) and sulfur. In another, oxygen optimizes the oxidation during combustion. Most refiners have chosen to use MTBE over other oxygenates primarily for its blending characteristics and for economic reasons. It is produced from natural gas, which is less expensive than oil.

Since 1992, MTBE has been used at higher concentrations in some gasoline to fulfill the oxygenate requirements set by the United States Congress in Clean Air Act amendments; however, since 1999, in California and other locations MTBE has begun to be phased out because of groundwater contamination (California Air Resources Board, 2004). Due to its higher solubility in water MTBE moves more quickly than other fuel components (California Air Resources Board, 2004). The Energy Policy Act of 2005 reduces the federal requirement for oxygen content in reformulated gasoline[2].

In 1995 high levels of MTBE were unexpectedly discovered in the water wells of Santa Monica, California, and the U.S. Geological Survey reported detections.[3] Subsequent U.S. findings indicate tens of thousands of contaminated sites in water wells distributed across the country. As per toxicity alone, MTBE is not classified as a hazard for the environment. The maximum contaminant level of MTBE in drinking water has not yet been established by the EPA. The leakage problem is partially attributed to the lack of effective regulations for underground storage tanks, but spillage from overfilling remains an important upset scenario. As an ingredient in unleaded gasoline, MTBE is the most soluble part. When dissolved in groundwater, MTBE will lead the contaminant plume with the remaining components such as benzene, toluene, etc. to follow. Thus the discovery of MTBE in public groundwater wells indicates that the contaminant source was a gasoline release. Its criticism and subsequent decreased usage, some claim, is more a product of its easy detectability (taste) in extremely low concentrations (ppb) than its toxicity, as benzene is much more toxic but remains a fuel additive. The MTBE concentrations used in the EU (usually 1.0–1.6%) and allowed (maximum 5%) in Europe are lower than in California.[4]

Alternatives

Other compounds are available as oxygenate additives for gasoline, for example ethanol and related ethers, e.g. tert-amyl methyl ether (TAME). Reasons for using MTBE include economic considerations, as some of the production is obtained by adding methanol to isobutylene produced as a by-product of other processes. However, most MTBE facilities have to manufacture the methanol and isobutylene required to produce MTBE.

Ethanol has been advertised as a safe alternative by the agricultural interest groups in the USA and Europe. Its lack of toxicity is not different from MTBE, but as a polar solvent, it drives off nonpolar hydrocarbons from the gasoline, a problem that MTBE does not cause. Volatile hydrocarbons in gasoline vapors are known carcinogens and produce photochemical smog.

Advocates of both sides of the debate in the United States sometimes claim that gasoline manufacturers have been forced to add MTBE to gasoline by law. It might be more correct to say they have been induced to do so, although any oxygenate would fulfill the law.

In 2003, California was the first state to start replacing the MTBE with ethanol. Several other states started switching soon afterward.

Higher quality gasoline is also an alternative, i.e., so that additives such as MTBE are unnecessary. Iso-octane itself is used. MTBE plants can be retrofitted to produce iso-octane from isobutylene.[5],[6] Iso-octane is the ideal gasoline, being the standard reference for the octane rating.

In the long run, diesel fuel is also an alternative, although it requires a major switchover to diesel-run cars. There are several varieties of biodiesel; both oxygen-containing esters and oxygen-free alkyl biodiesels are available.

As a solvent

As a solvent, MTBE possesses one distinct advantage over most ethers- it has a much lower tendency to form explosive organic peroxides. Opened bottles of diethyl ether or THF can build up dangerous levels of these peroxides in months, whereas samples of MTBE are usually safe for years (but they should still be tested periodically). For this reason (as well as its higher boiling point), it is used as a solvent extensively in industry, where safety concerns and regulations make working with diethyl ether, THF, or other ethers much more difficult and expensive. However, despite the popularity of MTBE in industrial settings, it is rarely used as a solvent in academia. Research volumes are much smaller, leading to lower risks from other ethers, and in addition the use of MTBE as a solvent is very rare in literature synthetic procedures.

As a chemical reagent

Being an ether, MTBE is a Lewis base. However, unlike other ethers such as diethyl ether or THF, it does not coordinate well enough with magnesium to be used for making Grignard reagents. The tert-butyl group is easily cleaved off under strongly acidic conditions (forming a moderately stable carbocation), particularly if heated (isobutylene is lost), something which can limit the use of MTBE as a solvent.

Persistence and pervasiveness in the environment

The main environmental risk of MTBE is that it gives water an unpleasant taste at even very low concentrations, and thus can easily render large quantities of groundwater non-potable. MTBE is often introduced into water-supply aquifers by leaking underground storage tanks (USTs) at gasoline stations. Although USTs are much better constructed now than in the 1980s, accidental releases still take place because of the very large number of USTs. The high solubility and persistence of MTBE cause it to travel faster and farther than many other components of gasoline when released into an aquifer. It is also released when gasoline containing MTBE is spilled onto the ground. Because it is water soluble, it easily moves through soil, polluting both surface and groundwater.[7]

MTBE has widespread occurrences in the aquifers of North America, where the majority of groundwater chemistry data has been acquired. As one regional example, the San Francisco Bay Area Regional Water Quality Control Board has indicated MTBE is one of the groundwater pollutants of most widespread concern in this metropolitan region.[8]

MTBE is biodegradable to CO2 and water under aerobic conditions with the correct bacteria. However, the natural occurrence of these bacteria with the ability to break ether bonds is not high, and it appears that most strains of MTBE-oxidizing bacteria are slow-growing bacteria with low biomass production per unit MTBE oxidized. In the proper type of bioreactor, such as a fluidized bed bioreactor, MTBE can be rapidly and economically removed from water to undetectable levels.

Health risks

The IARC, a cancer research agency of the World Health Organization, maintains MTBE is not classifiable as a human carcinogen. MTBE can be tasted in water at concentrations of 5 – 15 µg/l[9].

MTBE is not classified as a human carcinogen at low exposure levels by the International Agency for Research on Cancer (IARC).[10] However, exposure to large doses of MTBE carries significant non-cancer-related health risks. The effects of the prolonged presence of this alcohol derivative are not fully understood.

As of 2007, researchers have limited data about the health effects of ingestion of MTBE. The United States Environmental Protection Agency (EPA) has concluded that available data are not adequate to quantify health risks of MTBE at low exposure levels in drinking water, but that the data support the conclusion that MTBE is a potential human carcinogen at high doses.[11]

Legislation and litigation

United States

MTBE is difficult to clean up due to its high solubility in water. Estimates of the cost of removing MTBE from groundwater and soil contamination range from $1[12] to $30[13]billion, including removing the compound from aquifers and municipal water supplies and replacing leaky underground oil tanks. There is some controversy centered around the question of who will pay the costs of this remediation. In one case, the cost to oil companies to clean up the MTBE in wells belonging to Santa Monica is estimated to exceed $200 million.[14] However, if one used the presently available fluidized bed bioreactor technology to remove the MTBE in this Santa Monica case, the cost would be a small fraction of the suggested $200 million. It would be hard to justify the litigation cost, in this case, if it cost only a few million to clean it up.

Recent state laws have been passed to ban MTBE in certain areas. California and New York, which together accounted for 40% of U.S. MTBE consumption, banned the chemical starting January 1, 2004, and as of September 2005, twenty-five states had signed legislation banning MTBE. (A table of state by state information, as of 2002, is available at the United States Department of Energy website.[15]

In 2000, the EPAdrafted plans to phase out the use of MTBE nationwide over four years. As of fall 2006, hundreds of lawsuits are still pending regarding MTBE contamination of public and private drinking water supplies.

The Energy Policy Act of 2005, passed in the House on April 21, 2005, did not include a provision for shielding MTBE manufacturers from water contamination lawsuits. This provision was first proposed in 2003 and had been thought by some to be a priority of Tom DeLay and Rep. Joe Barton, chairman of the Energy and Commerce Committee.[16] This bill did include a provision that gives MTBE makers, including some major oil companies, $2 billion in transition assistance as MTBE is phased out over the next nine years.[17] Due to opposition in the Senate,[18] the conference report dropped all MTBE provisions. The final bill was passed by both houses and signed into law by President Bush.[19] The lack of MTBE liability protection is resulting in a switchover to the use of ethanol as a gasoline additive, which is in limited supply as of April 2006. Some traders and consumer advocates are blaming this for an increase in gasoline prices.[20]

Certain patents important in the manufacture of MTBE are not held by American companies; for example, United States patent 5536886, Process for preparing alkyl ethers,[21] is owned by the Finnish company Neste. The same corporation also went on to patent the replacement of the MTBE process, an octane production process trademarked NExOCTANE.

The EPA currently lists methyl tertiary butyl ether (MTBE) as a candidate for a maximum contaminant level (MCL) in drinking water[22]. MCLs are determined by the EPA using toxicity data.

References

- ↑ Michael Malveda, Hossein Janshekar, Masahiro Yoneyama. Gasoline Octane Improvers/Oxygenates. SRI Consulting. http://www.sriconsulting.com/CEH/Public/Reports/543.7500/

- ↑ http://www.epa.gov/otaq/rfg regs.htm#usage

- ↑ U.S. Geological Survay detections

- ↑ European Commission. MTBE and the Requirements for Underground Storage Tank Construction and Operation in Member States.

- ↑ http://www.nesteengineering.com/default.asp?path=111,360,362,477

- ↑ http://www.halliburton.com/kbr/hydroChem/petroChem/nexoctane.jsp

- ↑ Sierra Club on Gasoline Additive: MTBE

- ↑ San Francisco Bay Area Regional Water Quality Control Board Integrated Basin Management Plan (2004)

- ↑ Fischer A, Oehm C, Selle M, Werner P. (2005). "Biotic and abiotic transformations of methyl tertiary butyl ether (MTBE)". Environ Sci Pollut Res Int 12 (6): 381–6.. doi:. PMID 16305145.

- ↑ http://monographs.iarc.fr/ENG/Monographs/vol73/volume73.pdf

- ↑ http://www.epa.gov/mtbe/faq.htm#concerns

- ↑ SIGMA - Weekly Report

- ↑ Long Island Utility Fighting to Defeat MTBE Safe Harbor - Napoli Bern - Attorneys

- ↑ AmeriScan: February 17, 2005

- ↑ Website U.S. Department of Energy

- ↑ http://www.cnn.com/2005/POLITICS/04/21/energy.bill.mtbe.ap/

- ↑ http://www.msnbc.msn.com/id/7574562/+MTBE&hl=en

- ↑ Charles Babington, House Again Passes GOP Energy Measures, Washington Post, June 16, 2004, at A4 (House passes Energy Bill, but Senate opponents of MTBE provision in House Bill have the votes to prevent its enactment).

- ↑ http://thomas.loc.gov/cgi-bin/bdquery/z?d109:h.r.00006:

- ↑ prices ethanol/index.htm?cnn=yes http://money.cnn.com/2006/04/18/news/economy/gas prices ethanol/index.htm?cnn=yes

- ↑ http://www.freepatentsonline.com/5536886.html

- ↑ CCL 2 List

See also

- ETBE