Messerschmitt Bf 109

| Bf 109 | |

|---|---|

|

|

| Messerschmitt Bf 109G-10 at the National Museum of the United States Air Force in Dayton, Ohio | |

| Role | Fighter |

| Manufacturer | Bayerische Flugzeugwerke Messerschmitt |

| Designed by | Willy Messerschmitt |

| First flight | 28 May 1935 |

| Introduced | 1937 |

| Retired | 1945, Luftwaffe 1965, Spain |

| Status | Retired |

| Primary users | Luftwaffe Hungarian Air Force Italian Social Republic Air Force Romanian Air Force |

| Number built | more than 33,000 |

| Variants | Avia S-99/S-199 Hispano Aviacion Ha 1112 |

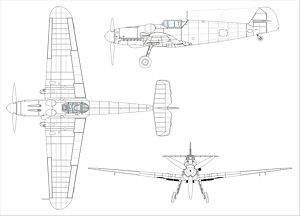

The Messerschmitt Bf 109 was a German World War II fighter aircraft designed by Willy Messerschmitt in the early 1930s. It was one of the first true modern fighters of the era, including such features as an all-metal monocoque construction, a closed canopy, and retractable landing gear. The Bf 109 was produced in greater quantities than any other fighter aircraft in history, with a total of 33,984 units produced up to April 1945.[1] Fighter production totalled 47% of all German aircraft production, and the Bf 109 accounted for 57% of all German fighter types produced.[2] A total of 2,193 Bf 109 A-E were built prewar, from 1936 to August 1939. Approximately 1,000 Bf 109 derivatives were manufactured postwar under licence as Czechoslovakian-built Avia S-99 & S-199s and Spanish-built Hispano Aviación HA-1109 and HA-1112 Buchons.

The Bf 109 was the backbone of the Luftwaffe fighter force in World War II, although it began to be partially replaced by the Focke-Wulf Fw 190 from 1941. The Bf 109 was the most successful fighter of World War II, shooting down more aircraft than any of its contemporaries. Originally conceived as an interceptor, it was later developed to fulfill multiple tasks, serving as bomber escort, fighter bomber, day-, night- all-weather fighter, bomber destroyer, ground-attack aircraft, and as reconnaissance aircraft. Although the Bf 109 had weaknesses, including short range[3] and challenging take off and landing characteristics, it stayed competitive with Allied fighter aircraft until the end of the war.

The Bf 109 was flown by the three top-scoring fighter aces of World War II: Erich Hartmann, the top scoring fighter pilot of all time claiming 352 victories, Gerhard Barkhorn with 301 victories, and Günther Rall claiming 275 victories. All of them flew with Jagdgeschwader 52, a unit which exclusively flew the Bf 109 and was credited with over 10,000 victories, chiefly on the Eastern Front. Hartmann chose to fly the Bf 109 in combat throughout the war, despite being offered the use of the Me 262. Hans-Joachim Marseille, the highest scoring German ace in the North African Campaign, also claimed all of his 158 victories flying the Bf 109, against Western Allied pilots.

The Bf 109 was also used with good results by non-German pilots, such as the Finnish fighter ace Ilmari Juutilainen with 94 victories, the highest scoring non-German fighter ace in World War II [4], Romanian fighter ace Alexandru Şerbănescu with 47 victories, Croatian fighter ace Mato Dukovac with 44 victories and Hungarian fighter ace Szentgyörgyi Dezső with 34 victories.

Contents

|

Designation

Bf 109 was the official Reichsluftfahrtministerium (German Aviation Ministry, RLM) designation, since the design was submitted by the Bayerische Flugzeugwerke company, and was used exclusively in all official German documents dealing with this aircraft family. The company was renamed Messerschmitt AG after July 1938[5] when Erhard Milch finally allowed Willy Messerschmitt to acquire the company; from that date forward, all Messerschmitt aircraft were to carry the "Me" designation except those already assigned a Bf prefix. Wartime documents from Messerschmitt AG, RLM, and others continued to use both designations,[6] sometimes even on the same page, but there were several RLM orders to deny acceptance of documents carrying the Me prefix for the Bf 109. Me 109 is known to have been the name used in print by Luftwaffe propaganda publications as well as by the Messerschmitt company itself after July 1938, and Luftwaffe personnel, who pronounced it may hundert-neun. The Me 109 ("emm ee one-oh-nine") designation was usually used in the English-speaking world. However, in both wartime and contemporary literature, both the "Bf" and "Me" as well as "ME" prefixes are used.[7] All extant airframes are described as "Bf 109" on identification plates, including the final K-4 models.[8]

Contest history

During 1933 the Technisches Amt (T-Amt), the technical department of the RLM, concluded a series of research projects into the future of air combat. The result of the studies was four broad outlines for future aircraft:

- Rüstungsflugzeug I for a multi-place medium bomber

- Rüstungsflugzeug II for a tactical bomber

- Rüstungsflugzeug III for a two-seat heavy fighter

- Rüstungsflugzeug IV for a single-seat fighter

Rüstungsflugzeug IV was intended to be an interceptor, replacing the Arado Ar 64 and Heinkel He 60 biplanes then in service. While it was intended the R-IV aircraft would best all others then flying, the requirements were nevertheless not terribly hard to meet.

The fighter needed to have a top speed of 400 km/h at 6,000 m (250 mph at 19,500 ft) which it could maintain for 20 minutes, while staying in the air for a total of 90 minutes. It was to be powered by the new Junkers Jumo 210 engine of about 700 hp (522 kW). It was to be armed with either a single high-performance 20 mm MG C 30 cannon firing through the engine shaft, or alternatively either two engine cowl-mounted 7.92 mm MG 17 machine guns, or one lightweight, engine mounted 20 mm MG FF cannon plus two 7.92 mm MG 17 machine guns.[9] One other specification was that the aircraft needed to keep wing loading below 100 kg/m²; wing-loading being a way of defining the aircraft's ability to turn and climb. The priorities for the fighter design were level speed, climb speed, and manoeuvrability, in that order.

In fact the R-IV specifications were not actually devised by the T-Amt at all. In early 1933 both Heinkel and Arado had sent in privately-funded designs for a monoplane fighter, and the T-Amt simply collected the best features from both and sent them back out again, adding Focke-Wulf to the tender. In May 1934 the R-IV request was distributed to the tendering companies and made official. Each was asked to deliver three prototypes to be delivered for head-to-head testing in late 1934.

Willy Messerschmitt was originally not invited to participate in the competition. This was mainly due to personal animosity between Messerschmitt and RLM director Erhard Milch (Hans Hackman, a close friend of Milch, was killed testing the prototype Messerschmitt M20 light transport aircraft), after the M20 proved a disaster in Lufthansa use. Nevertheless, Messerschmitt was on very good terms with many high ranking Luftwaffe officers based on the success of the Messerschmitt Bf 108 Taifun sports plane. After a delay of several months, Bayerische Flugzeugwerke (literally Bavarian Aircraft Factory) for which Messerschmitt was head designer, was invited to take part in early 1935, although Milch let it be known they would never win the contract.

Prototypes

The first prototype (Versuchsflugzeug 1 or V1), with the civilian registration D-IABI, was completed by May 1935, but the German engines were not yet ready. In order to get the designs into the air, the RLM acquired four Rolls-Royce Kestrel VI engines by trading Rolls-Royce a Heinkel He 70 Blitz as an engine test-bed.[10] Messerschmitt received two of these engines and started adapting the engine mounts of V1 to take the inverted Vee-12 engine. This work was completed in August, and V1 completed flight tests in September 1935. The aircraft was then sent to the Luftwaffe Test Center at Rechlin to take part in the design contest.

By the late summer, the Jumo engines were starting to become available, and V2 was completed with the 602 hp (449 kW) Jumo 210A in October 1935. V3 followed, being the first to actually mount guns, but another Jumo 210 was not available and it ended up delaying the flight of V3 until May 1936. Like V1, V2 and V3 were sent to Rechlin after acceptance tests at the factory.

The flight data of these three aircraft were very nearly identical. The maximum airspeed was about 470 km/h at 4,000 m altitude, and the service ceiling was about 8,300 m.

The contest

After Luftwaffe acceptance trials were completed at Rechlin, the prototypes were moved to Travemünde for the head-to-head portion of the contest. The aircraft which participated in the trials were the Arado Ar 80 V3, the Focke-Wulf Fw 159 V3, the Heinkel He 112 V4 and the Bf 109 V2. The He 112 arrived first, in early February 1936, and the rest of the prototypes had all arrived by the beginning of March.

Because most of the fighter pilots of the Luftwaffe were used to biplanes with open cockpits, low wing-loading, light g-forces and easy handling, they were very critical about the Bf 109 at first. However it was soon one of the front-runners in the contest, as the Arado and Focke-Wulf entries, which were intended as "back-up" programmes to safeguard against failure of the two favourites, proved to be completely outclassed. The Arado Ar 80, with its "gull" wing (replaced with a straight, tapered wing on the V3) and fixed, spatted undercarriage was overweight and underpowered and the design was abandoned after three prototypes had been built. The parasol winged Fw 159 was always considered by the Erprobungsstelle (E-Stelle) staff at Travemünde to be a compromise between the biplane and the aerodynamically more efficient low-wing monoplane. Although it had some advanced features, it used a novel undercarriage design which was never truly reliable.[11]

Initially the Bf 109 was regarded with suspicion by the E-Stelle test pilots because of its steep ground angle, resulting in poor forward view on the ground, the sideways hinged cockpit canopy which could not be opened in flight and the automatic wing leading edge slots which, it was thought, would inadvertantly open during aerobatics, possibly leading to crashes. They were also concerned about the high wing loading.[12]

The Heinkel He 112, based on a scaled down Blitz was the favourite of the Luftwaffe leaders. Compared with the Bf 109 it was also cheaper.[13] Positive aspects of the He 112 included the wide track and robustness of the undercarriage, considerably better visibility from the cockpit, and a lower wing loading that led to easier landings. However, the He 112 was also structurally complicated, being some 18% heavier than the Bf 109, and it soon became clear that the thick wing, which spanned 12.6 m (41ft 4 in) with an area of 23.2 m² (249.7 ft²) on the first prototype (V1), were a disadvantage for a light fighter, decreasing the aircraft's rate of roll and manoeuvrability. Because of its smaller, lighter airframe the Bf 109 was 30 km/h faster than the He 112 in level flight, and superior in climbing and diving. As a result the He 112 V4 which was used for the trials had new wings, spanning 11.5 m (37 ft 8.75 in) with an area of 21.6 m² (232.5 ft²). In addition the V4 had a single piece clear view sliding cockpit canopy and more powerful Jumo 210Da engine with a modified exhaust system. However the improvements had not been fully tested and the He 112 V4 was not able to be demonstrated in accordance with the rules laid down by the Acceptance Commission, giving a distinct advantage to the Bf 109. The Commission ruled in favour of the Bf 109 because of the Messerschmitt test pilot's demonstration of the 109's capabilities during a series of spins, dives, flick rolls and tight turns, throughout which the pilot was in complete control of the aircraft. [14]

Finally, In March the RLM received news that the Spitfire had been ordered into production; with this information a quick result to the contest was needed in order to get the winning design into production. On 12 March, they released a document that outlined the results of the contest, Bf 109 Priority Procurement, as a result of which the RLM instructed Heinkel to radically re-design the He 112 , while ordering the Bf 109 into production.[15]

Design features

As with the earlier Bf 108, the new design was based on Messerschmitt's "lightweight construction", which essentially aimed at reducing the total number of parts in the aircraft as much as possible. Examples of this could be found in the use of two large, complicated brackets which were fitted to the main engine firewall; these brackets incorporated the lower engine mounts and landing gear pivot points. Another large forging attached to the firewall carried the main-spar pick up points, and carried most of the wing loads. Contemporary design practice was usually to have these main load-bearing structures mounted on different parts of the airframe, with the loads being distributed through the main structure via a series of strong-points. By centralising the loads on the main bulkhead the main structure of the 109 was able to be made relatively light and uncomplicated.[16]

Another advantage of this design was that because the landing gear was attached to the fuselage , it was possible to completely remove the wings of the aircraft for major servicing without the need for additional equipment to support the fuselage. It also meant that the wing structure was able to be simplified through not having to carry the weight of the aircraft and not having to bear the loads imposed during take-off or landing. However, this had one major drawback — this landing gear arrangement ensured a narrow wheel track making the aircraft laterally unstable while on the ground. To increase stability the legs had to be splayed out, creating another problem in that loads imposed during take-off and landings were transferred at an angle up the legs. The small rudder of the 109 was relatively ineffective at controlling the strong swing created by the powerful slipstream of the propeller and this sideways drift created disproportionate loads on the wheel opposite the swing. If the forces imposed were large enough the pivot points often broke and the landing gear leg would be forced sideways into its bay. [17]

Because of the large ground angle caused by the long legs visibility for the pilot, especially straight ahead, was very poor, a problem exacerbated by the sideways opening canopy. This meant that the pilots often had to "snake" the aircraft during taxiing manoeuvres, which again imposed stresses on the splayed undercarriage legs.

Although it has been suggested that from 5–33% of all 109s were damaged or destroyed in this way, the Luftwaffe's loss records show that approximately 1% of the Bf 109s had suffered landing incidents or accidents at the beginning of its career, a figure comparable to the other monoplane fighters introduced at the time. Ground accidents were, however, more of a problem with rookie pilots, especially during the later stages of the war.[18] Even experienced pilots, especially those who were tired, were caught out. Most Finnish pilots report that the swing was easy to control, but some of the less experienced pilots lost fighters on startup.[18] As more powerful engines and larger propeller blades were used the swing became more pronounced, although the provision of a fixed "tall" tailwheel on some of the late G-10s and 14s and the K series helped alleviate the problem to a large extent.

Right from the inception of the design priority was given to total and easy access to the powerplant, fuselage weapons and other systems while the aircraft was operational from forward airfields. To this end the entire engine cowling was made up of large, easily removable panels which were secured by large toggle-latches. A large panel under the wing centre-section could be removed to gain access to the L-shaped main fuel tank, which was sited partly under the cockpit floor and partly behind the rear cockpit bulkhead. Other, smaller panels gave easy access to the cooling systems and electrical equipment. The engine was held in two large, forged, magnesium alloy y-shaped legs which were cantilevered from the main firewall/bulkhead. Each of the legs was secured by two quick-release screw fittings on the main firewall. All of the main pipe connections were colour-coded and grouped in one place, where possible, and the electrical equipment plugged into junction boxes mounted on the firewall. The entire powerplant could be removed or replaced as a unit in a matter of minutes.[19]

Reflecting Messerschmitt's belief in low-weight, low-drag, simple monoplanes, the armament was placed in the fuselage: two machine guns were mounted in the cowling, firing over the top of the engine while provision was made for a third, engine mounted weapon firing through the propeller hub,[20] with the engine buffering the recoil. Conforming to Dr. Messerschmitt's ethos, this kept his gun-free wings very thin and lightweight. When it was discovered the RAF was producing eight-gun monoplanes, it became clear the Bf 109 would need to carry more weaponry; a new wing was designed to carry machine guns, and later, 20 mm MG FF cannon configurations.

In 1938 the "Emil" entered production. To improve on the performance allowed by the rather small 600 to 700 hp Jumo, the larger Daimler Benz DB 601A engine was used, yielding an extra 300 hp at the cost of an additional 400 lb.

Another aspect of this construction technique was the use of a single, I-section main spar in the wing, mounted closer to the leading edge, forming a stiff D-shaped torsion box with it. Most aircraft of the era used two spars, near the front and rear, but the D-box was much stiffer torsionally, and eliminated the need for the rear spar. The wing profile was somewhere between NACA 2314 and 2315, with a thickness to chord ratio of 14.5%.

Another major difference was the much higher wing loading than the other designs. While the R-IV contract called for a wing loading of less than 100 kg/m², Messerschmitt felt this was unreasonable; with the engines available to them, the fighter would end up slower than the bombers it was tasked with catching.

A wing generates two forms of drag, parasitic drag due to its form, and induced drag which is a side effect of generating lift. The former dominates at high speeds, when the airflow hitting the wing causes drag that rises with the square of the aircraft's speed. The latter dominates at lower speeds, where the lack of airflow requires the wing to be angled into the airflow at a higher angle of attack. Since the fighter was being designed primarily for high speed flight, a smaller wing would be optimised for high speed use.

The downside of such a trade-off is that low-speed flight would suffer, as the smaller wing would require more airflow to generate enough lift to stay flying. In order to address this, the Bf 109 included advanced high-lift devices on the wings, including automatically opening slats on the leading edge, and fairly large camber-changing flaps on the trailing edge. Messerschmitt also included ailerons that "drooped" when the flaps were lowered thereby increasing the effective flap area when the flaps were deployed. When deployed, these devices effectively increased the coefficient of lift, making it better at low speeds and high angles of attack.

Another drawback of the high wing loading is that the fighter would require more energy to manoeuvre. The high lift devices would offset this to some degree, but they also increased drag. Given that manoeuvrability was last on the RLM's wish list, Messerschmitt was certain the benefits outweighed the drawbacks, and the Messerschmitt 109 was regarded by the Luftwaffe as the more manoeuvrable one of the two main Luftwaffe fighters, with benign stall characteristics and excellent controllability in a turn.

Wing armament and gondola cannons

By 1937 it had become clear that the 109 was too lightly armed, especially when compared with the eight machine guns which armed the new RAF fighters: the Hawker Hurricane and Supermarine Spitfire. The problem was that when it came to fitting additional armament the only place in which it could be located was in the wings. However, the positions of the undercarriage bays, main spar and wing slots meant that room was limited to two bays between the undercarriage and slots. There was room for only one weapon per wing, either an MG 17, or an MG FF or MG FF/M. The first version of the 109 to have wing guns was the C-1, which had one MG 17 per wing fitted in the inner bays. To avoid redesigning the wing to accommodate large ammunition boxes and access hatches, an unusual ammunition feed was devised whereby a continuous belt holding 500 rounds of ammunition, was fed along chutes out to the wingtips. The belt was fed around a roller and back along the wing, forward and beneath the gun breech, to the wing root where it was fed around another roller and back to the weapon. The gun barrels were buried in long, large diameter tubes between the spar and the leading edge. These tubes channelled cooling air around the barrels and breeches and out of a slot at the rear of the wing diaphragm and top of the flap. Room was still so restricted that parts of the MG 17's breech mechanism poked into an accommodating hole in the flap structure.[21]

The much longer and heavier MG FF had to be mounted in the outer bay. A large hole was cut through the spar webbing to allow the cannon to be fitted with an ammunition feed forward of the spar and the rear breech block projecting through the spar. The 60 round ammunition drum was placed in the machine-gun compartment; a small hatch incorporating a blister was needed in the wing lower surface to allow access to change the drum. The entire weapon could be removed for servicing by removing a leading edge panel.[21] From the 109F series onwards, guns were no longer carried inside the wings - a noteworthy exception was Adolf Galland's field-modified Bf 109F-2, which had a 2 cm MG FF/M installed internally in each wing.[22] As explained later some of the late 109K series models, such as the K-6, were planned to carry 3 cm MK 108s cannons in the wings.[23] - though additional firepower was available through a pair of 2 cm MG 151/20 cannons in gondola-shaped aerodynamic fairings, installed under the wings. Although the additional armament increased the fighter's potency as a bomber destroyer, it had an adverse affect on the handling qualities, reducing its competence in fighter-versus-fighter combat and accentuating the tendency of the fighter to swing pendulum-fashion in flight.[24] The cannon gondolas - without ammunition - weighted 135 kg.[25] Installation of the gondolas was a simple task that could be quickly performed by the units armourers, and imposed a reduction of speed of only 8 km/h.[26] By comparison the installed weight of a similar armament of two 2 cm MG 151/20 cannon inside the wings of the FW 190A-4/U8 was 130 kg, without ammunition.[27]

Records

On 11 November 1937 Messerschmitt regained some favour with Erhard Milch with the Bf 109 V13 increasing the world's air speed record for Landplanes with piston engines [28][29] to 379.38 mph (610.55 km/h). The "V13" had been fitted with a special racing DB 601R engine, as a result the power of the engine could reach 1,650 hp for short periods.[30]

Heinkel, having had the He 112 rejected began work on the He 100. On 6 June 1938 the He 100 V3, flown by Ernst Udet, established a new record of 394.4 mph (634.7 km/h), and later on 30 March 1939 test pilot Hans Dieterle surpassed that record reaching 463.92 mph (746.61 km/h) with the He 100 V8. Messerschmitt soon regained the lead in this race. On 26 April 1939 Flugkapitän Fritz Wendel, flying the Bf 209 V1 a racing aircraft bearing little in common with the Bf 109, powered by the DB 601ARJ, producing 1,550 hp but capable of reaching 2,300 hp, raised the figure to 469.22 mph (755.14 km/h). This world record for a propeller driven aircraft was to stand until 1969.[31]

Variants

Bf 109 A/B/C

The Bf 109A ("Anton") was the first version of the Bf 109. The armament, planned to be only two cowl-mounted 7.92 mm MG 17 machine guns. However, possibly due to the introduction of the Hurricane and Spitfire, each with eight machine guns, led to experiments with a third machine gun firing through the propeller shaft.[32] V4 and some A-0 were powered by a 640 PS Jumo 210B engine driving a two-bladed fixed-pitch propeller. As soon as the 670 PS Jumo 210D became available production was changed to this engine. The A-0 were not of a uniform type but saw several changes in their appearance. Visible changes include engine, cockpit and machine gun ventilation holes/slats as well as changing the location of the oil cooler several times to prevent overheating. Many of those Bf 109A-0 served with the Condor Legion and were often misidentified as B-series aircraft; they probably served in Spain with the tactical markings 6-1 to 6-16 . One A-0, marked as 6-15, ran out of fuel and was forced to land behind enemy lines. It was captured by Republican troops on 11 November 1937 and later transferred to the Soviet Union for a closer inspection.[33] 6-15 incorporated several improvements from the Bf 109B production program and was able to use the variable-pitch propeller.

According to RLM documentation 22 aircraft were ordered and delivered with V4 as the A-series prototype. [34]

The first Bf 109 in serial production, the Bf 109B ("Bruno"), was fitted with the 670 PS (660 hp, 493 kW) Jumo 210D engine driving a two-bladed fixed-pitch propeller. During the B-1 production run a variable pitch propeller was introduced and often retrofitted to older aircraft, these were then unofficially known as B-2s. Both versions saw combat with the Condor Legion during the Spanish Civil War, although it was apparent that the armament was still inadequate. Several aircraft were produced with an engine-mounted machine gun but it was very unreliable again, most likely because of engine vibrations and overheating. Thus the Bf 109 V8 was constructed to test the fitting of two more machine guns in the wings. Results showed that the wing needed strengthening. [35] In the following V9 prototype both wing guns were replaced by 20 mm MG FF cannons.[36]

A total of 341 Bf 109B of all versions were built by Messerschmitt, Fieseler, and Erla. [37]

The short-lived Bf 109C ("Caesar") was powered by a 700 PS Jumo 210G engine with direct fuel injection. Another important change was a strengthened wing, now carrying two more machine guns giving four MG 17 in total. The C-0 were pre-production aircraft, the C-1 was the production version, the C-2 an experimental version with an engine-mounted machine gun. The C-3 was planned with 20 mm MG FF cannons replacing the two MG 17 machine guns in the wings but its not known how many C-3 (if any) were built. The C-4 was planned to have an engine mounted MG FF, but the variant was not produced.[38]

A total of 58 Bf 109C of all versions were built by Messerschmitt. [37]

The next model, the V10 prototype, was identical to the V8, except for its Jumo 210G engine. The V10, V11, V12 and V13 prototypes were built using Bf 109B airframes, and tested the DB600A engine with the hope of increasing the performance of the aircraft. However the DB600A was found to be unreliable, and as the improved DB601A was to become available soon, the DB600A was dropped.

Bf 109D "Dora"

Developed from the V10 and V13 prototypes, the "Dora" was the standard version of the Bf 109 in service with the Luftwaffe during the period just before World War II. Despite this, the type saw only limited service during the war, as all of the 235 Doras still in service at the beginning of the Polish campaign were rapidly taken out of service and replaced by the Bf 109E, except in some night fighter units, where some examples were used into early 1940. Variants included D-0 and D-1 Models, both with a Junkers Jumo 210D engine and armed with two wing-mounted and two nose-mounted 7.92mm MG 17 machine guns.[39] The D-2 was an experimental version with an engine mounted machine gun but this installation failed again. The D-3 was similar to the C-3 with two 20mm MG FF cannon in the wings.

A total of 647 Bf 109D of all versions were built by Focke-Wulf, Erla, Fieseler, Arado and AGO. [37] Messerschmitt is listed as having only four Bf 109D produced, probably the D-0 preproduction series with the serial production transferred to license manufacturers. Several Bf 109D were sold to Hungary and Switzerland.

Bf 109E "Emil"

To test the new DB601A engine, with its 1,100 PS (1,085 hp, 809 kW), two more prototypes, the V14 and V15, were built, that differed in their armament. While the V14 was armed with the two MG 17 above the engine and one 20 mm MG FF cannon in each wing, the V15 was fitted with just two MG 17s mounted above the engine only.[40] After test fights the V14 was considered more promising and a pre-production batch of 10 E-0 was ordered. Batches of both E-1 and E-3 variants were shipped to Spain for evaluation, and received their baptism of fire in the final phases of the Spanish Civil War.

E-1

The production version E-1 kept the two 7.92 mm MG 17s above the engine and had two MG 17s in the wings. Later many were modified to the E-3 armament standard. The E-1B was a small batch of E-1s becoming the first operational Bf 109 fighter bomber, or Jagdbomber (usually abbreviated to Jabo). They were fitted with either a ETC 250 bomb rack, carrying one 250 kg bomb or two ETC 50 bomb racks, carrying a 50 kg bomb under each wing. The E-1 was also fitted with the Reflexvisier "Revi" gunsight. Communications equipment was the FuG 7 Funkgerät 7 (radio set) short-range radio equipment, effective to ranges of 30-35 miles. A total of 1,183 E-1 were built, 110 of them were E-1/B.[37]

E-2

The E-2 was not built for unknown reasons, probably another failed attempt to install an engine mounted machine gun or Motorkanone cannon.

E-3

To improve the performance of the Bf 109E, the last two real prototypes were constructed, the V16 and V17. They got some structural improvements and stronger armament. These prototypes were the basis of the Bf 109 E-3 version. They were armed with the two MG 17s above the engine and one MG FF cannon in each wing. [18] The E-3 also received additional armour, many receiving self sealing fuel tanks and an optional, improved DB601Aa with 1,175 PS (1,159 hp, 864 kW) respectively. A total of 1,276 E-3 were built, 83 of them were E-3a export versions for Yugoslavia without equipment classified as secret. They were carried Swiss MG and German Telefunken radios.[41]

E-4

The E-3 was replaced by the E-4 (with many airframes being upgraded to E-4 standards starting at beginning of the Battle of Britain) which was different in some small details, most notably by the modified MG-FF/M wing cannon and by improved head armor for the pilot. The MG FF/M fired a new and improved type of explosive shell, called Minengeschoß (or 'mine-shell') which was made by drawn steel (the same way brass cartridges are made) instead of being cast as was the usual practice. This resulted in a shell with a thin but strong wall, which had a larger cavity in which to pack a much larger explosive charge than was otherwise possible. The new shell required modifications to the MG FF's mechanism due to the different recoil characteristics, hence the MG FF/M-this special /M designation has also been thought to designate a Motorkanone version of the MG FF cannon.

The canopy was also revised to an easier-to-produce, "squared-off" design, and stayed fairly unchanged until the introduction of welded, heavy framed canopy on the G series in the autumn of 1942. The E-4 would be the base for all further Bf 109 E developments. Some E-4 and later models got a further improved 1,175 PS DB601N high-altitude engine resulting in a slightly changed model number; this E-4/N, first appeared in July 1940. The E-4 was also available as fighter-bomber with equipment very similar to the previous E-1/B. It was known as E-4/B (DB 601Aa engine) and E-4/BN (DB 601N engine). 496 E-4 of all versions were built - 250 E-4, 20 E-4/N, 211 E-4/B and 15 E-4/BN.[41]

E-5, E-6

The E-5 and E-6 were both reconnaissance variant with a camera installation behind the cockpit. The E-5 was a reconnaissance variant of the E-3, the E-6 was a reconnaissance variant of the E-4/N. 29 E-5s were built and 9 E-6 were ordered. [41]

E-7

The E-7 was the next major production variant, entering service in the end of August 1940. One of the limitations of the early Emils was short range of 660 km (410 miles) and limited endurance, as the design was originally conceived as a short ranged interceptor. The E-7 rectified this problem as it was the first subtype to able to carry a drop tank on a rack under the fuselage, which greatly increased their range to 1,325 km (820 miles); alternatively, a bomb could be fitted and the E-7 could be used as fighter-bomber. Previous Emil subtypes were progressively retrofitted with the necessary fittings for carrying a drop tank from October 1940. Early E-7s were fitted with the DB 601Aa, while later ones were fitted with DB 601N engines with increased output - the latter was designated as E-7/N.

Emils in the Battle of Britain

The E-1 and E-4 saw the most heavy action during the Battle of Britain — most of the E-3s were already converted to E-4 standard. The fuel-injected DB601 proved most useful against the British Supermarine Spitfire and Hawker Hurricane, as the British fighters used gravity-fed carburetted engines, which would cut out under negative g forces whereas the DB601 did not. The Bf 109s thus had the initial advantage in dives, either during attack or to escape. The Spitfire proved a formidable opponent, being approximately as fast and able to out-turn the 109 at medium to high speeds, due to the Bf 109's high wing loading. On the question of comparative turning circles in combat, Spitfires and Hurricanes benefited from their lower wing loading compared with the Bf109; 22 to 24 pounds per square foot on the RAF machines against 32 pounds per square foot for the Bf 109. Royal Aircraft Establishment estimated the Spitfire's turning circle — without height loss — as 696 feet (212 m) in radius (the Hurricane's would be slightly tighter) while the 109E's was estimated as 885 feet (270 m) radius at 3657 meters (12,000 feet).[42] Reports by Messerschmitt A.G. on the other hand give the smallest turning circle was 170 m, and fighter pilots on both sides claim they would out-turn their opponents in combat. Radinger and Schick, quoting the 1939 Luftwaffe specifications for the Bf 109E[43], state the tightest turn radius at ground level as 125 m (410 ft), and as 230 m (754 ft) at 6 km (20,000 feet)[44] In roll rates the Bf 109 enjoyed an advantage at dogfight speeds, though at high speeds the manoeuvrability of all three fighters was severely limited in this regard. The Bf 109 enjoyed good handling near stalling speed. In the Battle of Britain, the Bf 109 was at a disadvantage due to its short range. After escorting bombers from their bases in northern France, The Netherlands and Germany, the Messerschmitt had only around 15 minutes of fuel for combat over southern England before having to turn back. The Spitfire and Hurricane, operating virtually over their home airfields and having a greater range, had a tactical advantage in being able to remain longer in the combat area and having the option to pursue any targets if needed.

Firepower was comparable, with the Spitfire and Hurricane having eight .303 inch (7.7 mm) machine-guns versus the Bf 109's two 7.92 mm MG 17s and two 20 mm MG FF cannon. However, the MG FF had a small (60-round) ammunition capacity, a different ballistic properties than the cowl mounted MG 17s. RAF pilots who tested captured Bf 109s liked the engine and throttle response but criticised the high speed handling characteristics, poorer turning circle, greater force required on the control column at speed, and the thick framing of the cockpit glazing which they felt created blindspots in the pilot's field of vision.[42]

In August 1940 comparative trials were held at the E-Stelle in Rechlin, with the famous ace Werner Mölders being one of the participants. The tests concluded that the Bf 109 had superior level and climb speed to the Spitfire at all altitudes, but also noted the significantly smaller turning circle of the British fighter. It was advised not to engage in turning dog-fights unless the performance advantage of the Bf 109 could be used to full effect. The roll rate of the Bf 109 was deemed superior as was its stability on target approach. Mölders himself called the Spitfire "miserable as a fighting aircraft", due to its two-pitch propeller and the inability of its carburettor to handle negative g-forces. It should be noted, however, that in the political climate of the times there was often a considerable amount of propaganda written into such reports by both sides.[45]

Bf 109E variants and sub-variants

- E-0 (Pre-Production Aircraft with four MG 17 7.92 mm machine guns)

- E-1 (Similar to E-0)

- E-1/B (Fighter-bomber version of E-1, usually with DB 601Aa)

- E-2 (Not built)

- E-3 (Armament; 2x MG 17s in the cowl, 2x MG FFs in the wing roots. Modified canopy)[18]

- E-4 (Armor and structural improvements, change of MG FF cannons to MG FF/M. Return to 'normal' canopy)

- E-4/B (Fighter-bomber version of E-4, one 250 kg bomb, usually with DB 601Aa)

- E-4/Trop (Version of E-4 modified to serve in tropical regions)

- E-4/N (E-4 with DB601N engine)

- E-4/BN (Fighter-bomber version of E-4/N, one 250 kg bomb)

- E-5 (Recon version of E-3, camera equipment, two MG 17)

- E-6 (Recon version of E-4/N, camera equipment, two MG 17)

- E-7 (Similar to E-4 but with optional external fuel tank)

- E-7/N (Similar to E-4/N but with optional external fuel tank)

- E-7/NZ (also E-7/Z) E-7/N with additional GM-1 injection system

- E-7/U2 (Ground attack variant of E-7)

- E-8 (long range version of E-1 using drop tank installation of E-7, four MG 17)

- E-9 (Recon version of E-7/N, drop tank, camera equipment, two MG 17)

Bf 109F "Friedrich"

Prototypes

Development of the new Bf 109F airframe had begun in 1939. After February 1940 an improved engine, the Daimler-Benz DB 601E, was developed for use with the Bf 109. The engineers at the Messerschmitt facilities took two Bf 109E-1 airframes and installed this new powerplant. The first two prototypes, V21 (Werksnummer (Works number) or W.Nr 5602) and V22 (W.Nr 1800) kept the trapeziform wing shape from the E-1, but the span was reduced by 61 cm (2 ft) by "clipping" the tips. Otherwise the wings incorporated the cooling system modifications described below. V22 also became the testbed for the pre-production DB 601E. The smaller wings had a detrimental effect on the handling so V23, Stammkennzeichen (factory Code[46]) CE+BP, W.Nr 5603, was fitted with new, semi elliptical wingtips. The fourth prototype, V24 VK+AB, W.Nr 5604, flew with the clipped wings but featured a modified, "elbow" shaped supercharger air intake which was eventually adopted for production, and a deeper oil cooler bath beneath the cowling.[47] On all of these prototypes the fuselage was cleaned up and the engine cowling modified to provide improved aerodynamics.

Aerodynamic improvements

Compared to the earlier Bf 109 E, the Bf 109 F was much improved aerodynamically. The engine cowling was redesigned to be smoother and more rounded. The enlarged propeller spinner, adapted from that of the new Messerschmitt Me 210, now blended smoothly into the new engine cowling.[48] Underneath the cowling was a revised, more streamlined oil cooler radiator and fairing. A new ejector exhaust arrangement was incorporated and on later aircraft used a metal shield over the left hand banks to deflect exhaust fumes away from the supercharger air intake. The supercharger air-intake was, from the F-1 series on, a rounded, "elbow" shape which protruded further out into the air stream. A new 3 bladed, light alloy VDM propeller unit with a reduced diameter of 3 meters (9 ft 8.5 in) was used. Propeller pitch was changed electrically, and was regulated by a constant speed unit, though a manual override was still provided. Thanks to the improved aerodynamics, more fuel efficient engines and the introduction of light-alloy drop tanks, the Bf 109F offered a much increased maximum range of 1,700 km (1,060 miles)[49] compared to the Bf 109E's maximum range of 660 km (410 miles).

The canopy stayed essentially the same as that of the E-4 although the handbook for the F stipulated that the forward, lower triangular panel to starboard was to be replaced by a metal panel with a port for firing signal flares. Many F-1s and F-2s kept this section glazed. A two-piece, all metal armour plate head shield was added, as on the E-4, to the hinged portion of the canopy, although some lacked the curved top section. A bullet-resistant windscreen could be fitted to the windscreen as an option.[50] The fuel tank was self-sealing, and around 1942 Bf 109Fs were retrofitted with additional armour made from layered light alloy plate just aft of the pilot and fuel tank. The fuselage aft of the canopy remained essentially unchanged in its externals.

The tail section of the aircraft was redesigned as well. The rudder was of slightly reduced in area and the symmetrical fin section changed to an airfoil shape, which helped increase the effectiveness of the rudder. The conspicuous bracing struts were removed from the horizontal tailplanes which were placed slightly below and forward of their original positions. A semi-retractable tailwheel was fitted and the main undercarriage legs were raked forward by six degrees to improve the ground handling. An unexpected flaw of the tail section was revealed as the first Bf 109Fs were rushed into service; consequently some aircraft crashed or nearly crashed, with either the wing surface wrinkling or fracturing, or by the tail structure failing. In one such accident, the commander of JG 2 "Richthofen", Wilhelm Balthasar lost his life when he was attacked by a Spitfire during a test flight. While making an evasive manoeuvre, the wings broke away and Balthasar was killed when his aircraft hit the ground. When the wreck was investigated, not a single bullet hole was found. Slightly thicker wing skins and reinforced spars dealt with the wing problems. Tests were also carried out to find out why the tails had failed and it was found that at certain engine settings a high-frequency oscillation in the tailplane spar was overlapped by vibrations from the engine; together this was enough to cause structural failure at the rear fuselage/fin attachment point. Initially two external stiffening plates were screwed onto the outer fuselage on each side and later the entire structure was reinforced.[47]

The entire wing was redesigned, the most obvious change being the new elliptical wingtips, and the slight reduction of the aerodynamic area to 16.05 square meters. Other features of the redesigned wings included newly leading edge slats, which were slightly shorter but had a slightly increased chord, and new rounded, removable wingtips which changed the profile of the wings and increased the span slightly over that of the E series. Friese type ailerons replaced the plain type ailerons of the previous models. 2R1 profile was used with a thickness to chord ratio of 14.2% at the root reducing to 11.35% at the last rib. As before, dihedral was 6° 32'.[48]

The wing radiators were shallower and set farther back on the wing. A new cooling system was introduced which was automatically regulated by a thermostat with interconnected variable position inlet and outlet flaps which would balance the lowest drag possible with the most efficient cooling possible. A new radiator, shallower but longer than that fitted to the E was developed. A boundary layer duct allowed continual airflow to pass through the airfoil above the radiator ducting and exit from the trailing edge of the upper split flap. The lower split flap was mechanically linked to the central "main" flap, while the upper split flap and forward bath lip position were regulated via a thermostatic valve which automatically positioned the flaps for maximum cooling effectiveness. [51] In 1941 "cutoff" valves were introduced which allowed the pilot to shut down either wing radiator in the event of one being damaged; this allowed the remaining coolant to be preserved and return to base with the damaged aircraft. However, these valves were delivered to frontline units as kits, the number of which, for unknown reasons, was limited.[52] These cutoff valves were later factory standard fitting for Bf 109G[53] and K series[54].

Armament

The armament of the Bf 109F was revised and now consisted of the two synchronized 7.92mm MG 17s with 500 rounds per gun above the engine plus a Motorkanone cannon firing through the propeller hub. Several aces, particularly Oberst Adolf Galland, criticised the light armament as inadequate for the average pilot. Major Walter Oesau refused to fly an F as long as Emil's were still available. Only after a lack of spare parts, did he accept an F. Werner Mölders on the other hand saw the single centerline gun as an improvement. It is possible that the criticism of the Bf 109F's armament is based on the early F-2 version with the 15 mm MG 151/15 cannon, which was later replaced by the 20 mm version of the same weapon and was praised for being highly effective by aces like Günther Rall.

With the early tail unit problems problems out of the way, pilots generally agreed that the F series were the best-handling of all the Bf 109 series.[55] Werner Mölders flew one of the first operational Bf 109F-1s over England from early October 1940; he may well have been credited with shooting down eight Hurricanes and four Spitfires while flying W.No 5628, Stammkennzeichen SG+GW between 11 October and 29 October 1940.[56][57]

Bf 109F variants and sub-variants

F-0, F-1, F-2

As the DB601E was not yet available in numbers the pre-production F-0 (the only F variant to have a rectangular supercharger intake) and the first production series F-1/F-2 received the 1,175 PS (875 kW) DB 601N engine driving a VDM 9-11207 propeller.[48] The F-0/F-1 and F-2 only differed in their armament, the F-1 being fitted with one 2cm MG FF/M 2cm Motorkanone firing through the engine hub, with 60 rounds of ammunition. The F-1 first saw action in the Battle of Britain in October 1940 with JG 51.[58] A total of 208 F-1s were built between August 1940 and February 1941 by Messerschmitt Regensburg and the Wiener Neustädter Flugzeugwerke.[59]

The F-2 introduced the 15 mm Mauser MG 151/15 with 200 rounds of ammunition.[60] The Motorkanone was supplemented by two synchronized 7.92mm MG 17 machineguns, mounted under the engine cowl, with 500 rounds of ammunition per gun. As the harder hitting 2cm version of the same gun become available, a number of F-2s were retrofitted with it on the field. About 1380 F-2s were built between October 1940 and August 1941 by AGO, Arado, Erla, Messerschmitt Regensburg and WNF.[61] No tropicalized version was built, although individual F-2s were retrofitted with sand filter in the field.[62] The maximum speed of the F-1 and F-2 was 615 kph (382 mph) at rated altitude.

- F-0 (Pre-Production Aircraft built from E series airframes, Adolf Galland was one of the few to fly one operationally)

- F-1 (Armed with one MG FF/M 2cm Motorkanone cannon and two 7.92 mm MG 17 machine guns)

- F-2 (Armed with one MG 151 15 mm cannon and two MG 17)

- F-2/trop tropicalized version

F-3, F-4, F-5, F-6

The 1,350 PS (1,005 kW) DB 601E was used in the F-3 and F-4 model together with a VDM 9-12010 propeller with broader blades for improved altitude performance.[47][63] The DB 601 E was initially restricted to 1,200 H.P. at 2,500 rpm.[63]; the full rating of 1,350 PS at 2,500 rpm was cleared for service use by February 1942.[64] As opposed to the DB 601N which run on 100 octane aviation fuel designated as 'C-3' by the Luftwaffe, the DB 601 E was satisfied with the use of 87 octane 'B-4', despite its improved performance.[65]

Only a handful of fifteen examples the F-3 are believed to have been produced by Messerschmitt Regesnburg between October 1940 and January 1941. Like the F-1, the F-3 was armed with the 2cm MG-FF/M and two 7.92mm MG 17s.[66]

From the F-4 onward, the new 2cm Mauser MG 151/20 with 200 rounds of ammunition used.[67] The first F-4s reached frontline units in June 1941. Production lasted exactly a year between May 1941 and May 1942, with 1841 of all F-4 variants produced.[68] Some of the later models were capable of mounting two 15mm MG 151/15 cannons under the wing in faired gondolas with 135 rounds of ammunition per gun. These were designated as F-4/R1s, and 240 of them was produced by W.N.F. in the first quarter of 1942.[69] This optional armament for additional armament was standardized as field kit for later G and K series. A special high altitude variant, designated F-4/Z was also built with a production run of 544[70] in the first quarter of 1942 with GM-1 boost and saw extensive use.[71] Finally, the Erla factory produced 576 tropicalized F-4/trops in the first half of 1942.[72]

With its initial engine rating of 1200 PS, the maximum speed of the F-4 (and F-3) was 635 kph (394 mph) at rated altitude; with the clearance of the full rating of 1350 PS, maximum speed increased to 670 kph (416 mph).[73]

- F-3 (As F-1 with 601E engine, produced in limited numbers )

- F-4 (DB 601E engine, armed with one MG 151/20 2cm cannon and two 7.92mm MG 17s)

- F-4/R1 (As F-4, but capable of mounting two 15 mm MG 151/15 cannons in underwing gondolas)

- F-4/Z (As F-4, high altitude fighter, with GM-1 boost)

- F-5 (Recon version of F-4, only two MG 17)

- F-6 (Recon version of F-4, improved camera equipment)

Bf 109G "Gustav"

Introduction

The Bf 109 G-series was developed from the F-series airframe and was largely identical to it, although there were detail differences. Modifications included reinforced wing structure, an internal bullet-proof windscreen, the use of heavier, welded framing for the cockpit transparencies, and additional light-alloy armour for the fuel tank. It was originally intended that the wheel wells would incorporate small doors to cover the outer portion of the wheels when retracted. To incorporate these the outer wheel bays were squared off. Two small inlet scoops for additional cooling of the spark plugs were added on both sides of the forward engine cowlings. A less obvious difference was the omission of the boundary layer bypass outlets, which had been a feature of the F series, on the upper radiator flaps.[74][75]

The G-series was designed to adapt to different operational tasks with greater versatility, using field kits known as Rüstsätze. Special high-altitude interceptors with GM 1 high-altitude boost and pressurized cockpits were also produced.

The newly fitted Daimler-Benz DB 605A series was a development of the DB 601E engine utilised by the preceding Bf 109F-4. This was achieved through increasing the displacement and the compression ratio, as well as other detail improvements. Takeoff and emergency power of 1,475 H.P. was achieved with 1.42 ata of boost at 2,800 rpm. The DB605 suffered from reliability problems during the first year of operation, and this output was initially banned by VT-Anw.Nr.2206, forcing Luftwaffe units to limit maximum power output to 1,310 PS (975 kW) at 2,600 rpm and 1.3 atm manifold pressure. The full output was not reinstated until 8 June 1943 when Daimler-Benz issued a technical directive.[76] Up to 1944, the G series was powered the 1,475 PS Daimler-Benz DB 605 driving a three-blade VDM 9-12087A variable-pitch type with a diameter of 3 meters with even broader blades than as on the F series. Pitch control, as on the 109F, either "electro-mechanical"" (automatic) or "manual-electric" using a thumb-switch on the throttle lever.[77] From 1944 a new high altitude propeller with broader blades was introduced, designated VDM 9-12159, and was fitted to high altitude variants with the DB 605AS or D series engines.

The early versions of the Bf 109G closely resembled the Bf 109F-4 and carried the same basic armament - however, as the basic airframe was modified to keep pace with different operational requirements, the basically clean design began to change. From the spring of 1943, the G-series saw the appearance of bulges in the cowling when the 7.92 mm MG 17 was replaced with the 13 mm MG 131 heavy machine guns (G-5 onwards) due to the latter's much larger breechblock, and on the wings (due to larger tyres), leading to the Bf 109G-6s nickname "Die Beule" ("The Bulge"). The Gustav continued to be improved constantly: cockpit visibility, firepower in the form of the 30mm MK 108 cannon was added to the basic design in 1943, and a new, enlarged supercharger for the DB605, an enlarged vertical stabilizer (G-5 onwards), MW 50 power boost in 1944. It has been suggested the added weight of the new engines and heavier armament adversely affected the handling characteristics of the Bf 109, especially since it already had a high wing loading. While technically the statement is true, it is somewhat unfair as analysis show only a modest increase in weight as a result of development, fairly comparable to the development trend with Western Allied fighters.

Erich Hartmann, the World's top scoring fighter ace , claiming 352 victories, flew only the Bf 109G, of which he said:

It was very manoeuverable, and it was easy to handle. It speeded up very fast, if you dived a little. And in the acrobatics manoeuver, you could spin with the 109, and go very easy out of the spin. The only problems occurred during take-off. It had a strong engine, and a small, narrow-tread undercarriage. If you took off too fast it would turn [roll] ninety degrees away. We lost a lot of pilots in take-offs.[78]

From the Bf 109G-5 on an enlarged wooden tail unit (identifiable by a taller vertical stabilizer and rudder with a morticed balance tab, rather than the angled shape) was often fitted. This tail unit was standardised on G-10s and K-4s. Although the enlarged tail unit improved handling, especially on the ground, it weighed more than the standard metal tail unit, and required that a counterweight was fitted in the nose, increasing the variant's overall weight.[79]

With the Gustav, a number of special versions were introduced to cope with special mission profiles. Here, long range fighter-reconnaissance and high-altitude interceptors can be mentioned. The former were capable of carrying two 300 litre (66 Imp gal) droptanks, one under each wing, the latter received pressurized cockpits for pilot comfort and GM-1 nitrous oxide "boost" for high altitudes. The latter system was capable of increasing engine output for limited periods by 300 horsepower above the rated altitude and high altitude performance above of that of any Allied fighter in service in 1942-43.

Early Gustav models

G-1, G-2

The G-1, produced from February 1942, was the first of the G-series. This was the first production Bf 109 with a pressurized cockpit and could be identified by the small, horn-shaped air intake for the cockpit compressor just above the supercharger intake, on the left upper cowling. In addition, the angled armour plate for the pilot's head was replaced by a vertical piece which sealed-off the rear of the side hinged cockpit canopy. Small, triangular armour-glass panels were fitted into the upper corners of this armour, although there were aircraft in which the plate was solid steel. Silica gel capsules were placed in each pane of the windscreen and opening canopy to absorb any moisture which may have been trapped in the double glazing. The last 80 G-1s built were lightweight G-1/R2s. In these GM-1 nitrous oxide 'boost' was used, and the pilot's back armour was removed, as were all fittings for the long range drop tank. A few G-1s flown by I./JG 1 are known to have carried the underwing, MG 151/20 20mm cannon gondolas.[80] Maximum speed, at the initial reduced rating of the DB 605A-1 engine, was 660 km/h at 7,000 m altitude. If the GM-1 booster was fitted, the Gustav was even faster at altitude; with a Bf 109G-1/R2 with GM-1injection, R. Klein had achieved 680 km/h at 12,000 m and a ceiling of 13,800 m.

The G-2, which started production in May 1942 lacked the cabin pressurization and GM-1 installation .[81] Performance-wise it was identical to the G-1. The canopy reverted to one layer of glazing and incorporated the angled head armour used on the F-4, although several G-2s had the vertical type of the G-1. Several Rüstsätze could be fitted, although installing these did not change the designation of the aircraft. Instead the /R suffix referred to the G-2s Rüstzustand or equipment condition of the airframe, which was assigned at the factory, rather than in the field. There were two Rüstzustand planned for G-2s:

- G-2/R1: had one 300 litre drop tank beneath each wing, plus an ETC bomb rack under the fuselage, capable of carrying a 500 kg bomb and an auxiliary undercarriage unit beneath the fuselage. Also could carry a large jettisonable tail wheel, just aft of the cockpit.[82]

- G-2/R2: a reconnaissance aircraft with GM-1 and camera equipment.

The rack and internal fuel lines for carrying a 300 litre drop-tank were widely used on G-2s, as were the underwing MG 151/20 cannon gondolas. Several G-2s were fitted with the ETC 500 bomb rack, capable of carrying one 250 kg bomb. The final G-2 production batches built by Erla and Messerschmitt Regensburg were equipped as tropical aircraft (often referred to as G-2 trop), equipped with a sand-filter on the front of the supercharger intake and two small, teardrop shaped metal brackets on the left side of the fuselage, below the cockpit sill. These were used as mounts for specially designed sun umbrellas (called Sonderwerkzeug or Special tool), which were used to shade the cockpit.[83]

167 G-1s were built between February and June 1942, and 1586 G-2s between May 1942 and February 1943; one further G-2 was built in Győr, Hungary, in 1943.[74] Maximum speed of the G-2 was 537 km/h at sea level and 660 km/h at 7,000 m rated altitude with the initial reduced 1.3 atm rating. Performance of the G-1 was similar, but above rated altitude the GM-1 system could be used for additional performance: 680 km/h could be achieved at 12,000 meters.

The following variants of the G-1 and G-2 were produced:

- G-0 (Pre-production aircraft, powered by a DB 601E engine)

- G-1 (Pressurized fighter, w. GM 1)

- G-1/R2 (Reconnaissance fighter)

- G-1/U2 (High altitude fighter with GM-1)

- G-2 (Light fighter)

- G-2/R1 (Long-range Fighter-bomber or JaboRei- 2x 300 liter underwing drop tanks, one 500 kg bomb under fuselage, extended second tail wheel for large bombs)

- G-2/R2 (Reconnaissance fighter)

- G-2/trop (Tropicalized fighter)

G-3, G-4

In September 1942 the G-4 appeared; this version was identical to the G-2 in all respects, including performance, except for being fitted with the FuG 16 V.H.F. radio set, which provided much clearer radio transmissions and had three times the range of the earlier H.F. sets. Externally this could be recognised by the position of the fuselage antenna lead-in which was moved further aft to between frames seven and eight on the fuselage spine.[84] Due to the steady weight increases of the 109, from the spring of 1943 larger 660 x 160 mm mainwheels were introduced, replacing the previously used 650 x 150 mm. The undercarriage legs were altered so that the wheel's vertical axis was nearly upright rather than being parallel with the oleo leg. These changes resulted in the fitting of teardrop shaped fairings to the upper wing surface above the wheel-wells to accommodate the upper part of the mainwheels. The larger wheels and fairings were often retro-fitted to G-2s.[85] In addition a larger 350 x 135 mm tailwheel replaced the original 290 x 110 mm one; the larger tailwheel no longer fitted the recess, so the retraction mechanism was disconnected and the tailwheel fixed down.[86] Up to July 1943, 1,242 G-4s were produced, and an additional 4 were produced in Győr and WNF factories in the second half of 1943.[87] 50 examples of a pressurized version, G-3 were also produced between January-February 1943, this was similar to the G-1 although it was equipped with the V.H.F. radio set FuG 16 as the G-4.

The following variants of the G-3 and G-4 were produced:

- G-3 (Pressurized fighter, as G-1 with FuG 16 V.H.F. radio; only 50 built)

- G-4 (Fighter)

- G-4/R2 (Reconnaissance fighter)

- G-4/R3 (Long-range Reconnaissance fighter, with 2 x 300 liter underwing droptanks)

- G-4/trop (Tropicalized fighter)

- G-4/U3 (Reconnaissance fighter)

- G-4y (Command fighter)

G-5, G-6

In February 1943 the G-6 was introduced with the 13 mm MG 131s, replacing the smaller 7.92 mm MG 17 - externally this resulted in two sizeable blisters over the guns. These bulges reduced speed by nine km/h.

Over 12,000 examples were built well into 1944; the exact number being impossible to ascertain due to numerous variants and rebuilds. The G-5 was identical to the G-6 with pressurized cockpit, and of which 475 examples were built between May 1943 and August 1944. The G-5/AS was the first to be equipped with a DB 605AS engine for high altitude missions. GM-1-boosted G-5 and G-6 variants received the additional designation of /U2.

The G-6/U4 variant was armed with a 30 mm MK 108 cannon mounted as a Motorkanone firing through the propeller hub instead of the 20 mm MG 151/20. The G-6 was very often seen during 1943 fitted with assembly sets, used to carry bombs or a drop tank, for use as night-fighter, or to increase fire power by adding rockets or extra gondola guns.

The following variants of the G-5 and G-6 were produced:

- G-5 (Pressurized fighter)

- G-5/U2 (High altitude fighter with GM1 boost)

- G-5/U2/R2 (High altitude Reconnaissance fighter with GM1 boost)

- G-5/AS (High altitude fighter with DB605AS)

- G-5y (Command fighter)

- G-6 (Light fighter)

- G-6/R2 (Reconnaissance fighter, with MW 50)

- G-6/R3 (Long-range Reconnaissance fighter, with 2 x 300 liter underwing droptanks)

- G-6/trop (Tropicalized fighter)

- G-6/U2 (Fitted with GM-1)

- G-6/U3 ((Reconnaissance fighter)

- G-6/U4 (MK108 Motorkanone 30 mm engine cannon)

- G-6y (Command fighter)

- G-6/AS (High altitude fighter with DB605AS)

- G-6/ASy (High altitude command fighter)

- G-6N (Night fighter, usually with R6 and FuG 350Z Naxos)

- G-6/U4 N (as G-6N but with 30 mm MK 108 Motorkanone engine cannon)

Late Gustav models

Improvements to the design

During the course of 1943, a number of improvements were gradually introduced. In an attempt to increase his field of view an armoured glass head-rest, the so-called Galland Panzer begun to be fitted in the spring of 1943, replacing the bulky armour plate. Towards the end of the year the clear-view Erla Haube canopy appeared, eventually replacing the older heavily framed two-piece canopy on the Bf 109G, named after one of the sub-contractors involved in building the Bf 109. The canopy structure was completely redesigned to incorporate a greater area of clear perspex, the welded framing was reduced to a minimum and there was no longer a fixed rear portion, with the entire structure aft of the windscreen being hinged to swing to starboard when opened.[88]

The Bf 109 G-10, AS-engined G-5s, G-6s and G-14s as well as the K-4 saw a refinement of the engine cowlings. The blisters which had formally covered the spent shell-casing chutes of the MG 131s became more streamlined and were lengthened and enlarged to cover both the weapons and the engine bearers. Initial prototype versions were symmetrical, but as larger superchargers were fitted, the engines required modified upper engine bearers to clear the supercharger housing, and as a result the final shape of the new cowling was asymmetrical, being enlarged on the port size where the supercharger was mounted on the DB engine. There were also special streamlined panels fitted to the forward fuselage. These so-called agglomerations could be seen in several different patterns. Because of their aerodynamically more efficient form in a side view of DB 605AS and D powered Bf 109 Gs and Ks the agglomerations were barely discernible compared with the conspicuous fairings they replaced.[89]

Late production G-6, G-14, G-14/AS

Some versions of the G-6 and later Gs had a taller tail unit and redesigned rudder which improved stability at high speeds. The introduction of the WGr. 21 cm under-wing mortar/rockets and the 30 mm MK 108 cannon increased firepower. Certain production batches of the Gustav were fitted with aileron Flettner tabs to decrease stick forces at high speeds. Advanced radio/navigational equipment was also introduced.

Subsequent Bf 109G versions were basically modified versions of the G-6. Early in 1944, new engines with larger superchargers for improved high-altitude performance (DB 605AS), or with MW-50 water injection for improved low/medium altitude performance (DB 605AM), or these two features combined (DB 605ASM) were introduced into Bf 109 G-6. Maximum speed of the G-5/G-6 was 500-510 km/h at sea level, 625-630 km/h at 6,600 m-rated altitude using the restricted 1.3 atm boost, and when using the full 1.42 atm boost 530 and 640 km/h respectively. Figures are without MW-50 or GM-1 boost.

The G-14, appearing in mid-1944, was basically a late-war Bf 109 G-6 with the aforementioned improvements standardized, and with MW 50 methanol/water injection increasing output to 1800 hp being a standard fitting. High-altitude models of the G-14 received the DB 605ASM engine and were named G-14/AS. There was increasing tendency to use wood on some less vital parts (e.g. on a taller tailfin/rudder unit, pilot seat or instrument panel) - not because of the shortage of strategic materials like aluminium as often suggested, but as it allowed freeing up metalworking capacity by involving of the woodworking industry of more parts.

The following variants of the G-14 were produced:

- G-14 (Fighter; standardized late production G-6; MW 50 boost serial standard)

- G-14/AS (High altitude fighter with DB605ASM);

- G-14/ASy (High altitude command fighter);

- G-14y (command fighter);

- G-14/U4 (Fitted with MK 108 30 mm Motorkanone engine cannon)

G-10

Referred to as the "bastard aircraft of the Erla factory" in the Luftwaffe's Aircraft Variants Book of December 1944[90], the G-10 was a Bf 109 G airframe combined with the new DB 605D engine, in order to maintain production levels with minimal disruption of the production lines until production of K-series airframes would reach sufficient levels. Despite what the designation would suggest, it appeared in service after the G-14 in November 1944, largely replacing previous G-series aircraft on the production lines of Erla, WNF and Messerschmitt Regensburg factories. Evidence suggests that G-10s were rebuilt from older airframes supplementing production of the new K-4s with aircraft of almost equal value in the cheapest possible manner. One apparent indication was two aircraft identification plates on the port forward fuselage, below the windscreen rather than one.[91]

The most recognizable external change was the use of the "Erla-Haube" clear view canopy. Internal changes included inheriting the new 2000 W generator and the DB 605D engine of the 109K. Apart from the standardised streamlined engine cowlings the G-10s with the DB605D were equipped as standard with the MW-50 booster system (DB 605DM) and had a larger Fo 987 oil cooler housed in a deeper fairing. Also, because of the engine's enlarged crankcase and the oil return lines which ran in front of it, these G-10s had small blister fairings incorporated into the lower engine cowlings, forward of and below the exhaust stacks.[92]

The following variants of the G-10 were produced:

- G-10 (Light fighter with DB605DM or DB/DC engine)

- G-10/R2 (Bad-weather fighter with PKS 12 autopilot)

- G-10/R5 (Reconnaissance fighter)

- G-10/R6 (Bad-weather fighter)

- G-10/U4 (Fighter, with MK 108 Motorkanone 30 mm engine cannon)

Approximately 2,600 G-10s were produced from October 1944 until the war's end.

Miscellaneous variants: G-8, G-12

The G-8 was a dedicated reconnaissance version based on the G-6. The G-8 had often only the Motorkanone engine cannon or the cowling machine guns installed and there were several subversions for short or long range reconnaissance missions with a wide variety of cameras and radios available for use.[93]

The Bf 109 G-12 was a two-seat trainer version of the Bf 109. This was a conversion of "war weary" or rebuilt G-4 and G-6 airframes[94][95]; the space needed for the second cockpit was gained by reducing the internal fuel capacity to only 240 l meaning that the 300 l drop tank was employed as standard equipment. This version was rarely armed with anything more than one or two cowling machine guns.[96] The rear cockpit canopy was bowed out to give the instructor, who sat behind the student pilot in an armoured seat, a clearer view. The rear cockpit was also equipped with a basic instrument panel and all flight controls.

Bf 109G subtypes and variants

The base subtypes could be equipped with a Rüstsatz add-on standard field kits, in practice this meant hanging on some sort of additional equipment like droptanks, bombs or cannons to standard attachment points, present on all production aircraft. Aircraft could be modified in the factory with Umrüst-bausatz (Umbau) conversion kits or by adding extra equipment, designated as Rüstzustand, to convert standard airframes for special roles - a reconnaissance fighter or bad-weather fighter, for example. Unlike the Rüstsatz field-kits these modifications were permanent.

The Rüstsatz-kits were designated by the letter R and a Roman number. Rüstsatz-kits did not alter the aircraft's designation, so a Bf 109G-6 with Rüstsatz II (50 kg bombs) remained designated as Bf 109G-6, and not 'G-6/R2' - the G-6/R2 was a reconnaissance fighter with MW 50 - as suggested by most of the publications. The Umrüst-bausatz, Umbau. or Rüstzustand were identified with either an /R or /U suffix and an Arab number, i.e. Bf 109 G-10/U4.

Common Rüstsatz kits, Bf 109G[97]

- R I ETC 501/IX b bomb rack under the fuselage, fusing equipment for a SC 250 or SD 250 type 250 kg bomb

- R II ETC 50/VIII d bomb rack under the fuselage, fusing equipment, for four SC 50 type 50 kg bombs

- R III Schloß 503A-1 rack for one fuselage drop tank (300 l/79 US gallons).

- R IV two 3cm Rheinmetall-Borsig MK 108 underwing gunpods .

- R VI two 2cm Mauser MG 151/20 underwing gunpods with 135 rpg.

- R VII Peilrufanlage.

Common Umrüst-Bausatz [Umbau] numbers

- U1 Messerschmitt P6 reversible pitch propeller to be used as air brake, only prototypes

- U2 GM-1 boost, during 1944 several hundred converted to MW-50 boost

- U3 Reconnaissance conversion, in autumn 1943 G-6/U3 adopted as G-8 production variant

- U4 30 mm MK 108 Motorkanone engine-mounted cannon

Bf 109H

The Bf 109H was intended to be a high-altitude fighter, developed from the F-series. The wingspan was increased to 11.92 m, the stabilizer again received a strut leading to the fuselage, and it was also widened. Maximum speed was 750 km/h at 10,100 m. A small number of Bf 109H-1s were built, flying several sorties over Britain and France. Bf 109 H-2 and H-5 developments were also planned, before the entire H-series was scrapped because of wing flutter problems.[98]

- H-0 Pre-production aircraft, rebuilt from F-4/Z, powered by a DB 601E engine with GM-1 boost

- H-1 Production version, based on G-5 airframes, powered by a DB 605A engine with GM-1 boost

Bf 109K "Kurfürst"

K-4

The Bf 109K "Kurfürst" were the last of the series to see operational duty and the last in the Bf 109 evolutionary line. The K series was a response to the bewildering array of series, models, modification kits and factory conversions for the Bf 109, which made production and maintenance complicated and costly — something Germany could ill-afford late in the war. The RLM ordered Messerschmitt to rationalise production of the Bf 109, consolidating parts, types, and so on, to produce a uniform, standard model with better interchangeability of parts and equipment. At the same time, the existing flaws of the design were to be remedied. Work on the new version began in the spring of 1943, and the prototype was ready by the autumn of that year. Series production started in August 1944 with the K-4 model, due to changes in the design and delays with the new DB 605D powerplant. The K-4 was the only version to be mass produced.[99]

Externally the K series could be identified by changes in the locations of the radio equipment hatch,[100] which was moved forward and to a higher position between frames four and five, and the filler point for the fuselage fuel tank, which was moved forward to a location between frames two and three. In addition the D/F loop was moved aft to sit between frames three and four on the top fuselage spine and a small circular plate above the footstep on the port side of the fuselage was deleted. The rudder was fitted as standard with a Flettner tab and two fixed tabs although some rare examples were not fitted with the fixed tabs. All K-4s were to be fitted with a long retractable tailwheel (350 x 135 mm) with two small clamshell doors covering the recess when the tail-wheel was retracted.

The wings featured the large rectangular fairings for the large 660 x 190mm main wheels. Small wheel well doors, originally planned for the G series, were fitted to the outer ends of the wheel bays, covering the outer wheels when retracted. These doors were often removed by front-line units. The ailerons were fitted with small, adjustable trim tabs. The radio equipment was the FuG 16ZY with an antenna mast fitted under the port outer wing and FuG 25a IFF as well as the FuG 125 Hermine D/F equipment. Internally the oxygen bottles were relocated from the rear fuselage to the right wing.[101] Flettner tabs for the ailerons were also to be fitted to serial production aircraft to reduce control forces, but are only seen on photos of later production aircraft.

Armament of the K-4 consisted of a 3 cm MK 108 engine-mounted cannon (Motorkanone) with 65 rounds, and two 13 mm MG 131s in the nose with 300 rounds each although some K-4s were fitted with the MG 151/20 as the Motorkanone.[102] Additional Rüstsätze, or equipment kits, such as a 300 liter drop tank (R III), bombs up to the size of 500 kg (R I), under wing 2cm Mauser MG 151/20 cannon gondola pods (R IV) or 21cm Wfr.Gr. 21 rockets (as on the Gustav models) could be carried after minimal preparations; the latter two however were rarely used, but there is evidence that III./JG 26 were almost completely equipped with K-4s which were fitted with R IV. In addition there were problems with the 3 cm MK 108 Motorkanone:

The 30mm cannon were extremely potent weapons, but they had a tendency to jam, and apparently all of the K-4s supplied to III./JG 26 were also equipped with 20mm-guns in the hated underwing tubs. Uffz. Georg Genth's regular aircraft was a G-10, but on occasion he flew a K-4. He preferred the G-10 as a dogfighter, as the K-4's bulky armament sharply reduced its manouevrability.[103]

Power was provided by a Daimler-Benz DB 605DM (early models) of 1800 PS output and later the DB 605DB/DC powerplant with 1850/2000 PS output.[104] A wide-chord, three bladed VDM 9-12159 propeller of 3 meter diameter, optimized for high altitudes then converted this output into thrust.[105]

Deliveries began in mid-October 1944. 534 examples had been delivered by the Messerschmitt A.G., Regensburg by the end of November 1944,[106] and 856 by the end of the year.[107] Regensburg delivered a total of 1593 by the end of March 1945, after which production figures are missing. With such a high rate of production, despite continuous heavy fighting, by the end of January 1945 314 K-4s — about every fourth 109 — were listed on hand with the 1st line Luftwaffe units. Ultimately it was intended to equip all Bf 109 units with the 109K, which marked the final stage of 109 development before the jet age.[108]

The Bf 109 K-4 was the fastest 109 of world War II, reaching 715 km/h (445 mph) at 7,500 m altitude; improved propellers were being developed when the war ended which would boost the speed to 727 km/h (452 mph)[109], and 741 km/h (460 mph) was expected with a swept-back propeller design.[110] Rate of climb was outstanding, up to 4,820 ft (1,470 m)/min at 1.98 atm[109] and 4,525 ft (1,380 m)/min at 1.8 atm. With such improvements in performance, the Bf 109 remained comparable to opposing fighters until the end of the war. However, the deteriorating ability of the thousands of novice Luftwaffe pilots by this stage of the war meant the 109's strengths were of little value against the numerous and well-trained Allied fighter pilots.

Other Bf 109K projects and prototypes

Several other versions were projected based on the 109K airframe - K-6, K-8, K-10 and K-14. In the proposed K-6 the armament would have been two MG 131 above the engine, along with a MK 108 Motorkanone and an internally mounted MK 108 in each wing, with 45 rpg. Alternatively, the wing MK 108s could be substituted by 2cm MG 151/20s, with 100 rpg. Armour weight was increased to 200 lbs. Take-off weight was 7986 lbs. Some K-6 prototypes were built and tested at the Tarnewitz weapons-testing centre.

Project drawings of the K-10 show an K-series airframe powered by the two-stage DB 605L high altitude engine, a high-velocity 3cm MK 103mot Motorkanone, and two 3cm MK 108 cannons in the wings; the cowl 13mm MG 131s heavy machine guns were dispensed with.

Some sources point to limited use of the K-14, intended as high-altitude heavy fighter, but the type`s existence cannot be positively confirmed. The K-14 was powered by the DB 605L, with a rumoured use of a four bladed propeller, 460 mph and an operational altitude of 38,000 ft was projected. Armour and armament were otherwise similar to the K-6.