Hall effect

Legend:

1. Electrons (not conventional current!)

2. Hall element, or Hall sensor

3. Magnets

4. Magnetic field

5. Power source

Description

In drawing "A", the Hall element takes on a negative charge at the top edge (symbolised by the blue color) and positive at the lower edge (red color). In "B" and "C", either the electric current or the magnetic field is reversed, causing the polarization to reverse. Reversing both current and magnetic field (drawing "D") causes the Hall element to again assume a negative charge at the upper edge.

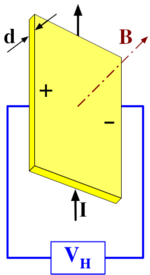

The Hall effect refers to the potential difference (Hall voltage) on the opposite sides of an electrical conductor through which there is an electric current, created by a magnetic field applied perpendicularly to the current. Edwin Hall discovered this effect in 1879.[1]

The ratio of the voltage created to the product of the current and the magnetic field (I*B) divided by the element thickness, is known as the Hall coefficient. It is a characteristic of the material from which the conductor is made, as its value depends on the type, number and properties of the charge carriers that constitute the current.

Contents |

Theory

The Hall effect comes about due to the nature of the current in a conductor. Current consists of the movement of many small charge-carrying "particles" (typically, but not necessarily, electrons). Moving charges experience a force, called the Lorentz Force, when a magnetic field is present that is not parallel to their motion.[2] When such a magnetic field is absent, the charges follow an approximately straight, 'line of sight' path. However, when a perpendicular magnetic field is applied, their path is curved so that moving charges accumulate on one face of the material. This leaves equal and opposite charges exposed on the other face, where there is a scarcity of mobile charges. The result is an asymmetric distribution of charge density across the Hall element that is perpendicular to both the 'line of sight' path and the applied magnetic field. The separation of charge establishes an electric field that opposes the migration of further charge, so a steady electrical potential builds up for as long as the charge is flowing.

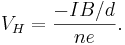

For a simple metal where there is only one type of charge carrier (electrons) the Hall voltage VH is given by

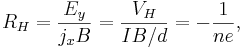

The Hall coefficient is defined as

where I is the current across the plate length, B is the magnetic flux density, d is the depth of the plate, e is the electron charge, j is the current density, and n is the charge carrier density of the carrier electrons.

As a result, the Hall effect is very useful as a means to measure both the carrier density and the magnetic field.

One very important feature of the Hall effect is that it differentiates between positive charges moving in one direction and negative charges moving in the opposite. The Hall effect offered the first real proof that electric currents in metals are carried by moving electrons, not by protons. The Hall effect also showed that in some substances (especially semiconductors), it is more appropriate to think of the current as positive "holes" moving rather than negative electrons.

Hall effect in semiconductors

When a current-carrying semiconductor is kept in a magnetic field, the charge carriers of the semiconductor experience a force in a direction perpendicular to the magnetic field and current. At equilibrium, a voltage appears at the semiconductor edges.

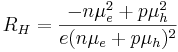

The simple formula for the Hall coefficient given above becomes more complex in semiconductors where the carriers are generally both electrons and holes which may be present in different concentrations and have different mobilities. For moderate magnetic fields the Hall coefficient is[3]

where  is the electron concentration,

is the electron concentration,  the hole concentration,

the hole concentration,  the electron mobility ,

the electron mobility ,  the hole mobility and

the hole mobility and  the absolute value of the electronic charge.

the absolute value of the electronic charge.

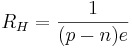

For large applied fields the simpler expression analogous to that for a single carrier type holds.

Technological applications

So-called "Hall effect sensors" are readily available from a number of different manufacturers, and may be used in various sensors such as rotating speed sensors, fluid flow sensors, current sensors, and pressure sensors. Other applications may be found in some electric airsoft guns and on the triggers of electropneumatic paintball guns.

Quantum Hall effect

For a two dimensional electron system which can be produced in a MOSFET. In the presence of large magnetic field strength and low temperature, one can observe the quantum Hall effect, which is the quantization of the Hall voltage.

Spin Hall effect

The Spin Hall effect consists in the spin accumulation on the lateral boundaries of a current-carrying sample. No magnetic field is needed. It was predicted by M.I. Dyakonov and V.I. Perel in 1971 and observed experimentally more than 30 years later, both in semiconductors and in metals, at cryogenic as well as at room temperatures.

Quantum Spin Hall effect

For HgTe two dimensional quantum wells with strong spin-orbit coupling, in zero magnetic field, at low temperature, the Quantum Spin Hall effect has been recently observed.

Hall effect in magnetic systems

In ferromagnetic materials (and paramagnetic materials in a magnetic field), the Hall resistivity includes an additional contribution, known as the Anomalous Hall Effect (or the Extraordinary Hall effect), which depends directly on the magnetization of the material, and is often much larger than the ordinary Hall effect. (Note that this effect is not due to the contribution of the magnetization to the total magnetic field.) Although a well-recognized phenomenon, there is still debate about its origins in the various materials. The anomalous Hall effect can be either an extrinsic (disorder-related) effect due to spin-dependent scattering of the charge carriers, or an intrinsic effect which can be described in terms of the Berry phase effect in the crystal momentum space (k-space).

Hall effect in ionized gases

(See Electrothermal instability)

The Hall effect in an ionized gas (plasma) is significantly different from the Hall effect in solids (where the Hall parameter is always very inferior to unity). In a plasma, the Hall parameter can take any value.

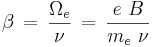

The Hall parameter β in a plasma is the ratio between the electron gyrofrequency Ωe and the electron-heavy particle collision frequency ν:

where

- e is the electron charge (1.6 × 10-19 coulomb)

- B is the magnetic field (in teslas)

- me is the electron mass (0.9 × 10-30 kg)

The Hall parameter value increases with the magnetic field strength.

Physically, the trajectories of electrons are curved by the Lorentz force. Nevertheless when the Hall parameter is low, their motion between two encounters with heavy particles (neutral or ion) is almost linear. But if the Hall parameter is high, the electron movements are highly curved. The current density vector J is no more colinear with the electric field vector E. The two vectors J and E make the Hall angle θ which also gives the Hall parameter:

Applications

Hall effect devices produce a very low signal level and thus require amplification. While suitable for laboratory instruments, the vacuum tube amplifiers available in the first half of the 20th century were too expensive, power consuming, and unreliable for everyday applications. It was only with the development of the low cost integrated circuit that the Hall effect sensor became suitable for mass application. Many devices now sold as "Hall effect sensors" are in fact a device containing both the sensor described above and a high gain integrated circuit (IC) amplifier in a single package. Recent advances have resulted in the addition of ADC (Analog to Digital) converters and I²C (Inter-integrated circuit communication protocol) IC for direct connection to a microcontroller's I/O port being integrated into a single package, see Advanced Hall Effect Current Transducer. Reed switch electrical motors using the hall effect IC is another application.

Hall probes are often used to measure magnetic fields, or inspect materials (such as tubing or pipelines) using the principles of Magnetic flux leakage.

Advantages over other methods

Hall effect devices when appropriately packaged are immune to dust, dirt, mud, and water. These characteristics make Hall effect devices better for position sensing than alternative means such as optical and electromechanical sensing.

When electrons flow through a conductor, a magnetic field is produced. Thus, it is possible to create a non-contacting current sensor. The device has three terminals. A sensor voltage is applied across two terminals and the third provides a voltage proportional to the current being sensed. This has several advantages; no additional resistance (a shunt, required for the most common current sensing method) need be inserted in the primary circuit. Also, the voltage present on the line to be sensed is not transmitted to the sensor, which enhances the safety of measuring equipment.

Ferrite toroid Hall effect current transducer

Hall sensors can detect stray magnetic fields easily, including that of Earth, so they work well as electronic compasses: but this also means that such stray fields can hinder accurate measurements of small magnetic fields. To solve this problem, Hall sensors are often integrated with magnetic shielding of some kind. For example, a Hall sensor integrated into a ferrite ring (as shown) can reduce stray fields by a factor of 100 or better. This configuration also provides an improvement in signal-to-noise ratio and drift effects of over 20 times that of a 'bare' Hall device. The range of a given feedthrough sensor may be extended upward and downward by appropriate wiring. To extend the range to lower currents, multiple turns of the current-carrying wire may be made through the opening. To extend the range to higher currents, a current divider may be used. The divider splits the current across two wires of differing widths and the thinner wire, carrying a smaller proportion of the total current, passes through the sensor.

The principle of increasing the number of 'turns' a conductor takes around the ferrite core is well understood, each turn having the effect of 'amplifying' the current under measurement. Often these additional turns are carried out by a staple on the PCB.

Split ring clamp-on sensor

A variation on the ring sensor uses a split sensor which is clamped onto the line enabling the device to be used in temporary test equipment. If used in a permanent installation, a split sensor allows the electrical current to be tested without dismantling the existing circuit.

Analog multiplication

The output is proportional to both the applied magnetic field and the applied sensor voltage. If the magnetic field is applied by a solenoid, the sensor output is proportional to product of the current through the solenoid and the sensor voltage. As most applications requiring computation are now performed by small (even tiny) digital computers, the remaining useful application is in power sensing, which combines current sensing with voltage sensing in a single Hall effect device.

Current sensing

By sensing the current provided to a load and using the device's applied voltage as a sensor voltage it is possible to determine the power dissipated by a device. This power is (for direct current devices) the product of the current and the voltage. With appropriate refinement the devices may be applied to alternating current applications where they are capable of reading the true power produced or consumed by a device.

Position and motion sensing

Hall effect devices used in motion sensing and motion limit switches can offer enhanced reliability in extreme environments. As there are no moving parts involved within the sensor or magnet, typical life expectancy is improved compared to traditional electromechanical switches. Additionally, the sensor and magnet may be encapsulated in an appropriate protective material.

Automotive ignition and fuel injection

Commonly used in distributors for ignition timing (and in some types of crank and camshaft position sensors for injection pulse timing, speed sensing, etc.) the Hall effect sensor is used as a direct replacement for the mechanical breaker points used in earlier automotive applications. Its use as an ignition timing device in various distributor types is as follows. A stationary permanent magnet and semiconductor Hall effect chip are mounted next to each other separated by an air gap, forming the Hall effect sensor. A metal rotor consisting of windows and tabs is mounted to a shaft and arranged so that during shaft rotation, the windows and tabs pass though the air gap between the permanent magnet and semiconductor Hall chip. This effectively shields and exposes the Hall chip to the permanent magnet's field respective to whether a tab or window is passing though the Hall sensor. For ignition timing purposes, the metal rotor will have a number of equal-sized tabs and windows matching the number of engine cylinders. This produces a uniform square wave output since the on/off (shielding and exposure) time is equal. This signal is used by the engine computer or ECU to control ignition timing. It is worth noting that many automotive Hall effect sensors have a built-in internal NPN transistor with an open collector and grounded emitter, meaning that rather than a voltage being produced at the Hall sensor signal output wire, the transistor is turned on providing a circuit to ground though the signal output wire.

Wheel rotation sensing

The sensing of wheel rotation is especially useful in anti-lock brake systems. The principles of such systems have been extended and refined to offer more than anti-skid functions, now providing extended vehicle handling enhancements.

Electric motor control

Some types of brushless DC electric motors use Hall effect sensors to detect the position of the rotor and feed that information to the motor controller.

Industrial applications

Applications for Hall Effect sensing have also expanded to the industrial/off-highway market, which now use Hall Effect Joysticks to control hydraulic valves, replacing the traditional mechanical levers. Such applications include; Mining Trucks, Backhoe Loaders, Cranes, Diggers, Scissor Lifts, etc. The leading manufacturer of Industrial Hall Effect Joysticks is P-Q Controls, Inc.,which was one of the first companies to expand the use of Hall Effect sensing to such applications in the 1980s, and in fact holds exclusive patents for contactless sensing.

The Corbino effect

The Corbino effect is a phenomenon similar to the Hall effect, but a disk-shaped metal sample plane of the disk, produces a "circular" current through the disk.

See also

|

|

References

- ↑ Edwin Hall (1879). "On a New Action of the Magnet on Electric Currents". American Journal of Mathematics 2: 287–92. doi:. http://www.stenomuseet.dk/skoletj/elmag/kilde9.html. Retrieved on 2008-02-28.

- ↑ "The Hall Effect". NIST. Retrieved on 2008-02-28.

- ↑ Kasap, Safa. "Hall Effect in Semiconductors". Archived from the original on 2008-11-01.

External links

- Patents

- U.S. Patent 1,778,796, P. H. Craig, System and apparatus employing the Hall effect

- General

- Interactive Java tutorial on the Hall Effect National High Magnetic Field Laboratory

- Science World (wolfram.com) article.

- "The Hall Effect". nist.gov.

- Hall, Edwin, "On a New Action of the Magnet on Electric Currents". American Journal of Mathematics vol 2 1879.

- Spin Hall Effect Detected at Room Temperature

- Hall Effect Sensing and Application. Honeywell documentation on hall effect sensing, interfacing and applications.