Combustion

Combustion or burning is a complex sequence of exothermic chemical reactions between a fuel and an oxidant accompanied by the production of heat or both heat and light in the form of either a glow or flames.

Direct combustion by atmospheric oxygen is a reaction mediated by radical intermediates. The conditions for radical production are naturally produced by thermal runaway, where the heat generated by combustion is necessary to maintain the high temperature necessary for radical production.

In a complete combustion reaction, a compound reacts with an oxidizing element, such as oxygen or fluorine, and the products are compounds of each element in the fuel with the oxidizing element. For example:

- CH4 + 2O2 → CO2 + 2H2O

- CH2S + 6F2 → CF4 + 2HF + SF6

A simpler example can be seen in the combustion of hydrogen and oxygen, which is a commonly used reaction in rocket engines:

- 2H2 + O2 → 2H2O(g) + heat

The result is water vapor.

In the large majority of the real world uses of combustion, the oxygen (O2) oxidant is obtained from the ambient air and the resultant flue gas from the combustion will contain nitrogen:

- CH4 + 2O2 + 7.52N2 → CO2 + 2H2O + 7.52N2 + heat

As can be seen, when air is the source of the oxygen, nitrogen is by far the largest part of the resultant flue gas.

In reality, combustion processes are never perfect or complete. In flue gases from combustion of carbon (as in coal combustion) or carbon compounds (as in combustion of hydrocarbons, wood etc.) both unburned carbon (as soot) and carbon compounds (CO and others) will be present. Also, when air is the oxidant, some nitrogen can be oxidized to various nitrogen oxides (NOx).

Contents |

Types

Rapid

Rapid combustion is a form of combustion in which large amounts of heat and light energy are released, which often results in a fire. This is used in a form of machinery such as internal combustion engines and in thermobaric weapons. Sometimes, a large volume of gas is liberated in combustion besides the production of heat and light. The sudden evolution of large quantities of gas creates excessive pressure that produces a loud noise. Such a combustion is known as an explosion.

Slow

Slow combustion is a form of combustion which takes place at low temperatures. Cellular respiration is an example of slow combustion.

Complete

In complete combustion, the reactant will burn in oxygen, producing a limited number of products. When a hydrocarbon burns in oxygen, the reaction will only yield carbon dioxide and water. When a hydrocarbon or any fuel burns in air, the combustion products will also include nitrogen. When elements such as carbon, nitrogen, sulfur, and iron are burned, they will yield the most common oxides. Carbon will yield carbon dioxide. Nitrogen will yield nitrogen dioxide. Sulfur will yield sulfur dioxide. Iron will yield iron(III) oxide. It should be noted that complete combustion is almost impossible to achieve. In reality, as actual combustion reactions come to equilibrium, a wide variety of major and minor species will be present. For example, the combustion of methane in air will yield, in addition to the major products of carbon dioxide and water, the minor product carbon monoxide and nitrogen oxides, which are products of a side reaction (oxidation of nitrogen).

Turbulent

Turbulent combustion is a combustion characterized by turbulent flows. It is the most used for industrial application (e.g. gas turbines, gasoline engines, etc.) because the turbulence helps the mixing process between the fuel and oxidizer.

Microgravity

Nearly every flame behaves differently in a microgravity environment; for example, a candle's flame takes the shape of a sphere[1]. Microgravity combustion research contributes to understanding of spacecraft fire safety and diverse aspects of combustion physics.

Incomplete

Incomplete combustion occurs when there isn't enough oxygen to allow the fuel (usually a hydrocarbon) to react completely with the oxygen to produce carbon dioxide and water, also when the combustion is quenched by a heat sink such as a solid surface or flame trap. When a hydrocarbon burns in air, the reaction will yield carbon dioxide, water, carbon monoxide, pure carbon (soot or ash) and various other compounds such as nitrogen oxides.

The quality of combustion can be improved by design of combustion devices, such as burners and internal combustion engines. Further improvements are achievable by catalytic after-burning devices (such as catalytic converters) or by the simple partial return of the exhaust gases into the combustion process. Such devices are required by environmental legislation for cars in most countries, and may be necessary in large combustion devices, such as thermal power plants, to reach legal emission standards.

The degree of combustion can be measured and analyzed, with test equipment. HVAC contractors, firemen and engineers use combustion analyzers to test the efficiency of a burner during the combustion process. In addition, the efficiency of an internal combustion engine can be measured in this way, and some states and local municipalities are using combustion analysis to define and rate the efficiency of vehicles on the road today.

Smouldering

Smouldering combustion is a flameless form of combustion, deriving its heat from heterogeneous reactions occurring on the surface of a solid fuel when heated in an oxidizing environment. The fundamental difference between smouldering and flaming combustion is that in smouldering, the oxidation of the reactant species occurs on the surface of the solid rather than in the gas phase. The characteristic temperature and heat released during smouldering are low compared to those in the flaming combustion of a solid. Typical values in smouldering are around 600 °C for the peak temperature and 5 kJ/g-O2 for the heat released; typical values during flaming are around 1500 °C and 13 kJ/g-O2 respectively. These characteristics cause smoulder to propagate at low velocities, typically around 0.1 mm/s, which is about two orders of magnitude lower than the velocity of flame spread over a solid. In spite of its weak combustion characteristics, smouldering is a significant fire hazard

Combustion with other oxidants

Oxygen can be assumed as the oxidant when talking about combustion, but other oxidants exist. Nitrous oxide is used in rockets and in motorsport; it produces oxygen at over 1300 C. Fluorine, another oxidizing element, can produce a combustion reaction, to produce fluorinated products (rather than oxides). For example, mixtures of gaseous fluorine and methane are explosive, just like mixtures of oxygen and methane. Chlorine trifluoride is a strong fluorinating agent that ignites fuels more readily than oxygen. Chlorine is another gaseous halogen capable of supporting a flame, producing chlorinated products.

Chemical equation

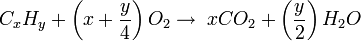

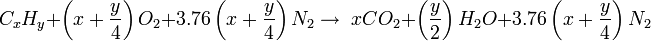

Generally, the chemical equation for stoichiometric burning of hydrocarbon in oxygen is as follows:

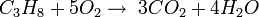

For example, the burning of propane is:

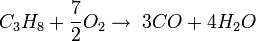

The incomplete combustion of propane is:

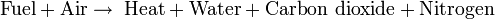

The simple word equation for the combustion of a hydrocarbon in oxygen is:

If the combustion takes place using air as the oxygen source, the nitrogen can be added to the equation, although it does not react, to show the composition of the flue gas:

For example, the burning of propane is:

The simple word equation for the combustion of a hydrocarbon in air is:

Nitrogen may also oxidize when there is an excess of oxygen. The reaction is thermodynamically favored only at high temperatures. Diesel engines are run with an excess of oxygen to combust small particles that tend to form with only a stoichiometric amount of oxygen, necessarily producing nitrogen oxide emissions. Both the United States and European Union are planning to impose limits to nitrogen oxide emissions, which necessitate the use of a special catalytic converter or treatment of the exhaust with urea.

Fuels

Liquid fuels

Combustion of a liquid fuel in an oxidizing atmosphere actually happens in the gas phase. It is the vapour that burns, not the liquid. Therefore, a liquid will normally catch fire only above a certain temperature: its flash point. The flash point of a liquid fuel is the lowest temperature at which it can form an ignitable mix with air. It is also the minimum temperature at which there is enough evaporated fuel in the air to start combustion.

Solid fuels

The act of combustion consists of three relatively distinct but overlapping phases:

- Preheating phase, when the unburned fuel is heated up to its flash point and then fire point. Flammable gases start being evolved in a process similar to dry distillation.

- Distillation phase or gaseous phase, when the mix of evolved flammable gases with oxygen is ignited. Energy is produced in the form of heat and light. Flames are often visible. Heat transfer from the combustion to the solid maintains the evolution of flammable vapours.

- Charcoal phase or solid phase, when the output of flammable gases from the material is too low for persistent presence of flame and the charred fuel does not burn rapidly anymore but just glows and later only smoulders.

Reaction mechanism

Combustion in oxygen is a radical chain reaction where many distinct radical intermediates participate.

The high energy required for initiation is explained by the unusual structure of the dioxygen molecule. The lowest-energy configuration of the dioxygen molecule is a stable, relatively unreactive diradical in a triplet spin state. Bonding can be described with three bonding electron pairs and two antibonding electrons, whose spins are aligned, such that the molecule has nonzero total angular momentum. Most fuels, on the other hand, are in a singlet state, with paired spins and zero total angular momentum. Interaction between the two is quantum mechanically a "forbidden transition", i.e. possible with a very low probability. To initiate combustion, energy is required to force dioxygen into a spin-paired state, or singlet oxygen. This intermediate is extremely reactive. The energy is supplied as heat. The reaction produces heat, which keeps it going.

Combustion of hydrocarbons is thought to be initiated by the abstraction of a hydride radical (H) from the fuel to oxygen, to give a hydroperoxide radical (HOO). This reacts further to give hydroperoxides, which break up to give hydroxyl radicals. There are a great variety of these processes that produce fuel radicals and oxidizing radicals. Oxidizing species include singlet oxygen, hydroperoxide, hydroxyl, monatomic oxygen, and hydroperoxyl (OH2). Such intermediates are short-lived and cannot be isolated. However, non-radical intermediates are stable and are produced in incomplete combustion. An example is acetaldehyde produced in the combustion of ethanol. An intermediate in the combustion of carbon and hydrocarbons, carbon monoxide, is of special importance because it is a poisonous gas.

Solid fuels also undergo a great number of pyrolysis reactions that give more easily oxidized, gaseous fuels. These reactions are endothermic and require constant energy input from the combustion reactions. A lack of oxygen or other poorly designed conditions result in these noxious and carcinogenic pyrolysis products being emitted as thick, black smoke.

Temperature

Assuming perfect combustion conditions, such as complete combustion under adiabatic conditions (i.e., no heat loss or gain), the adiabatic combustion temperature can be determined. The formula that yields this temperature is based on the first law of thermodynamics and takes note of the fact that the heat of combustion is used entirely for heating the fuel, the combustion air or oxygen, and the combustion product gases (commonly referred to as the flue gas).

In the case of fossil fuels burnt in air, the combustion temperature depends on all of the following:

- the heating value;

- the stoichiometric air to fuel ratio

;

; - the specific heat capacity of fuel and air;

- the air and fuel inlet temperatures.

The adiabatic combustion temperature (also known as the adiabatic flame temperature) increases for higher heating values and inlet air and fuel temperatures and for stoichiometric air ratios approaching one.

Most commonly, the adiabatic combustion temperatures for coals are around 2200 °C (for inlet air and fuel at ambient temperatures and for  ), around 2150 °C for oil and 2000 °C for natural gas.

), around 2150 °C for oil and 2000 °C for natural gas.

In industrial fired heaters, power plant steam generators, and large gas-fired turbines, the more common way of expressing the usage of more than the stoichiometric combustion air is percent excess combustion air. For example, excess combustion air of 15 percent means that 15 percent more than the required stoichiometric air is being used.

Instabilities

Combustion instabilities are typically violent pressure oscillations in a combustion chamber. These pressure oscillations can be as high as 180dB, and long term exposure to these cyclic pressure and thermal loads reduces the life of engine components. In rockets, such as the F1 used in the Saturn V program, instabilities led to massive damage of the combustion chamber and surrounding components. This problem was solved by re-designing the fuel injector. In liquid jet engines the droplet size and distribution can be used to attenuate the instabilities. Combustion instabilities are a major concern in ground-based gas turbine engines because of NOx emissions. The tendency is to run lean, an equivalence ratio less than 1, to reduce the combustion temperature and thus reduce the NOx emissions; however, running the combustion lean makes it very susceptible to combustion instabilities.

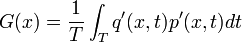

The Rayleigh Criterion is the basis for analysis of thermoacoustic combustion instabilities and is evaluated using the Rayleigh Index over one cycle of instability:

where q' is the heat release rate and p' is the pressure fluctuation.[2][3] When the heat release oscillations are in phase with the pressure oscillations, the Rayleigh Index is positive and the magnitude of the thermo acoustic instability increases. On the other hand, if the Rayleigh Index is negative, then thermoacoustic damping occurs. The Rayleigh Criterion implies that a thermoacoustic instability can be optimally controlled by having heat release oscillations 180 degrees out of phase with pressure oscillations at the same frequency. This minimizes the Rayleigh Index.

See also

Related concepts

|

Machines and equipment

|

Measurement techniques

Social applications and issues

|

References

- ↑ http://spaceflight.nasa.gov/history/shuttle-mir/science/mg/nm21460011.htm

- ↑ A. A. Putnam and W. C. Dennis (1953) "Organ-pipe oscillations in a flame-filled tube," Fourth Symposium (International) on Combustion, The Combustion Institute, pages 566-574.

- ↑ E. C. Fernandes and M. V. Heitor, “Unsteady flames and the Rayleigh criterion” in F. Culick, M. V. Heitor, and J. H. Whitelaw, ed.s, Unsteady Combustion (Dordrecht, the Netherlands: Kluwer Academic Publishers, 1996), page 4. Available on-line at: http://books.google.com/books?id=Je_hG6UfnogC&printsec=copyright&dq=rayleigh+thermoacoustic+&ie=ISO-8859-1&source=gbs_toc_s&cad=1#PPA4,M1

External links

- Hydrocarbon combustion Simple applet that illustrates the Chemical equation.

- Fuel efficiency (stoichiometric air fuel mixture) vs. decreased emissions in combustion engines

- Explaining burning using the candle.

- Fuel efficiency (stoichiometric air fuel mixture) vs. decreased emissions in combustion engines

- Simulation of gas combustion