Ammonium nitrate

| Ammonium nitrate | |

|---|---|

|

|

|

|

| IUPAC name | Ammonium nitrate |

| Identifiers | |

| CAS number | 6484-52-2 |

| UN number | 0222 – with > 0.2% combustible substances 1942 – with <= 0.2% combustible substances 2067 – fertilizers 2426 – liquid |

| RTECS number | BR9050000 |

| Properties | |

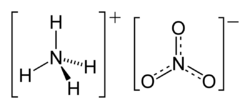

| Molecular formula | NH4NO3 |

| Molar mass | 80.04336 g/mol |

| Appearance | white solid |

| Density | 1.72 g/cm³, solid |

| Melting point |

169.6 °C |

| Boiling point |

approx. 210 °C decomp |

| Solubility in water | 119 g/100 ml (0 °C) 190 g/100 ml (20 °C) 286 g/100 ml (40 °C) 421 g/100 ml (60 °C) 630 g/100 ml (80 °C) 1024 g/100 ml (100 °C) |

| Explosive data | |

| Explosive velocity | 5,270 m/s |

| Hazards | |

| EU classification | not listed |

| NFPA 704 |

0

2

3

OX

|

| LD50 | 2085–5300 mg/kg (oral in rats, mice)[1] |

| Related compounds | |

| Other anions | Ammonium nitrite; ammonium perchlorate |

| Other cations | Sodium nitrate; potassium nitrate; hydroxylammonium nitrate |

| Related compounds | Nitrous oxide |

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C, 100 kPa) Infobox references |

|

The chemical compound ammonium nitrate, the nitrate of ammonia with the chemical formula NH4NO3, is a white powder at room temperature and standard pressure. It is commonly used in agriculture as a high-nitrogen fertilizer, and it has also been used as an oxidizing agent in explosives, including improvised explosive devices.

Contents |

Production

The processes involved in the production of ammonium nitrate in industry, although simple in chemistry, challenge technology: The acid-base reaction of ammonia with nitric acid gives a solution of ammonium nitrate:[2] HNO3(aq) + NH3(g) → NH4NO3(aq). For industrial production, this is done using anhydrous ammonia gas and concentrated nitric acid. This reaction is violent and very exothermic. After the solution is formed, typically at about 83% concentration, the excess water is evaporated to an ammonium nitrate (AN) content of 95% to 99.9% concentration (AN melt), depending on grade. The AN melt is then made into "prills" or small beads in a spray tower, or into granules by spraying and tumbling in a rotating drum. The prills or granules may be further dried, cooled, and then coated to prevent caking. These prills or granules are the typical AN products in commerce.

The Haber process combines nitrogen and hydrogen to produce ammonia, part of which can be oxidised to nitric acid and combined with the remaining ammonia to produce the nitrate. Another production method is used in the so-called Odda process.

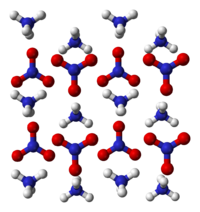

Crystalline phases

Transformations of the crystal states due to changing conditions (temperature, pressure) affect the physical properties of ammonium nitrate. The following crystalline states have been identified:

| System | Temperature (°C) | State | Volume Change (%) |

|---|---|---|---|

| - | >169.6 | liquid | - |

| I | 169.6 to 125.2 | cubic | +2.1 |

| II | 125.5 to 84.2 | tetragonal | -1.3 |

| III | 84.2 to 32.3 | α-rhombic | +3.6 |

| IV | 32.3 to −16.8 | β-rhombic | −2.9 |

| V | −16.8 | tetragonal | - |

The type V crystal is a quasi-cubic form which is related to caesium chloride, the nitrogens of the nitrates and the ammoniums are at the sites in a cubic array where Cs and Cl would be in the CsCl lattice. See C.S. Choi and H.J. Prask, Acta Crystallographica B, 1983, 39, 414-420.

Disasters

Ammonium nitrate decomposes into gases including oxygen when heated (non-explosive reaction); however, ammonium nitrate can be induced to decompose explosively by detonation. Large stockpiles of the material can be a major fire risk due to their supporting oxidation, and may also detonate, as happened in the Texas City disaster of 1947, which led to major changes in the regulations for storage and handling.

There are two major classes of incidents resulting in explosions:

- In the first case, the explosion happens by the mechanism of shock to detonation transition. The initiation happens by an explosive charge going off in the mass, by the detonation of a shell thrown into the mass, or by detonation of an explosive mixture in contact with the mass. The examples are Kriewald, Morgan (present-day Sayreville, New Jersey) Oppau, Tessenderlo and Traskwood.

- In the second case, the explosion results from a fire that spreads into the ammonium nitrate itself (Texas City, Brest, Oakdale), or from a mixture of ammonium nitrate with a combustible material during the fire (Repauno, Cherokee, Nadadores). The fire must be confined at least to a degree for successful transition from a fire to an explosion (a phenomenon known as "deflagration to detonation transition", or DDT). Pure, compact AN is stable and very difficult to initiate. However, there are numerous cases when even impure AN did not explode in a fire.

Ammonium nitrate decomposes in temperatures above 210 °C. Pure AN is stable and will stop decomposing once the heat source is removed, but when catalysts are present (combustible materials, acids, metal ions, chlorides. ..) the reaction can become self-sustaining (known as self-sustaining decomposition, SSD). This is a well-known hazard with some types of NPK fertilizers, and is responsible for the loss of several cargo ships.

References

- ↑ Martel, B.; Cassidy, K. (2004). Chemical Risk Analysis: A Practical Handbook. Butterworth–Heinemann. pp. 362. ISBN 1903996651.

- ↑ http://www.google.com/patents/pdf/Process_of_producing_concentrated_soluti.pdf?id=XronAAAAEBAJ&output=pdf&sig=ACfU3U0iYFRDUxltKLaVind-3wwP_JYPxg

- Properties: UNIDO and International Fertilizer Development Center (1998), Fertilizer Manual, Kluwer Academic Publishers, ISBN 0-7923-5032-4.

External links

- "Storing and Handling Ammonium Nitrate", UK Health and Safety Executive publication INDG230 (1986)

- Specific Heat Capacity as function of temperature - on-line calculation