Aluminium oxide

| Aluminium oxide | |

|---|---|

|

|

|

|

| Identifiers | |

| CAS number | 1344-28-1 |

| ChemSpider ID | |

| Properties | |

| Molecular formula | Al2O3 |

| Molar mass | 101.96 g/mol |

| Density | 3.97 g cm−3, solid |

| Melting point |

2054 °C |

| Boiling point |

2980 °C [1] |

| Solubility in water | insoluble |

| Structure | |

| Coordination geometry |

octahedral |

| Thermochemistry | |

| Std enthalpy of formation ΔfH |

−1675.7 kJ mol−1 |

| Standard molar entropy S |

50.92 J mol−1 K−1 |

| Hazards | |

| EU classification | Not listed. |

| Flash point | non-flammable |

| Related compounds | |

| Other anions | aluminium hydroxide |

| Other cations | boron trioxide gallium oxide indium oxide thallium oxide |

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C, 100 kPa) Infobox references |

|

Aluminium oxide is an amphoteric oxide of aluminium with the chemical formula Al2O3. It is also commonly referred to as alumina or aloxite[2] in the mining, ceramic and materials science communities. It is produced by the Bayer process from bauxite. Its most significant use is in the production of aluminium metal, although it is also used as an abrasive due to its hardness and as a refractory material due to its high melting point.[3]

Contents |

Natural occurrence

Corundum is the most common naturally-occurring crystalline form of aluminium oxide. Much less-common rubies and sapphires are gem-quality forms of corundum with their characteristic colors due to trace impurities in the corundum structure. Rubies are given their characteristic deep red color and their laser qualities by traces of the metallic element chromium. Sapphires come in different colors given by various other impurities, such as iron and titanium.

Properties

Aluminium oxide is an electrical insulator but has a relatively high thermal conductivity (40 W/m K). In its most commonly occurring crystalline form, called corundum or α-aluminium oxide, its hardness makes it suitable for use as an abrasive and as a component in cutting tools.[3]

Aluminium oxide is responsible for metallic aluminium's resistance to weathering. Metallic aluminium is very reactive with atmospheric oxygen, and a thin passivation layer of alumina quickly forms on any exposed aluminium surface. This layer protects the metal from further oxidation. The thickness and properties of this oxide layer can be enhanced using a process called anodising. A number of alloys, such as aluminium bronzes, exploit this property by including a proportion of aluminium in the alloy to enhance corrosion resistance. The alumina generated by anodising is typically amorphous, but discharge assisted oxidation processes such as plasma electrolytic oxidation result in a significant proportion of crystalline alumina in the coating, enhancing its hardness.

Aluminium oxide was taken off the United States Environmental Protection Agency's chemicals lists in 1988. Aluminium oxide is on EPA's TRI list if it is a fibrous form.[4]

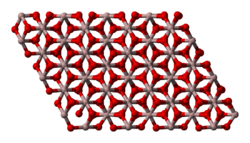

Crystal structure

The most common form of crystalline alumina, α-aluminium oxide, is known as corundum. Corundum has a trigonal Bravais lattice with a space group of R-3c (number 167 in the International Tables). The primitive cell contains two formula units of aluminium oxide. The oxygen ions nearly form a hexagonal close-packed structure with aluminium ions filling two-thirds of the octahedral interstices. Alumina also exists in other phases, namley eta, chi, gamma, delta and theta aluminas.[5] Each has a unique crystal structure and properties. The so-called β-alumina proved to exhibit a NaAl11O17-type lattice.[6]

Production

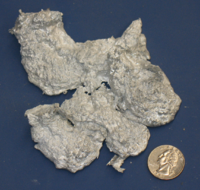

Aluminium oxide, also known as alumina, is the main component of bauxite, the principal ore of aluminium. The largest manufacturers in the world of alumina are Alcoa, Alcan and Rusal. Companies which specialize in the production of specialty aluminium oxides and aluminium hydroxides include Alcan and Almatis. The bauxite ore is made up of impure Al2O3, Fe2O3, and SiO2. Bauxite is purified by the Bayer process:

- Al2O3 + 3 H2O + 2 NaOH → 2NaAl(OH)4

The Fe2O3 does not dissolve in the base. The SiO2 dissolves as silicate Si(OH)62-. Upon filtering, Fe2O3 is removed. When the Bayer liquor is cooled, Al(OH)3 precipitates, leaving the silicates in solution. The mixture is then calcined (heated strongly) to give aluminium oxide:[3]

2Al(OH)3 + heat → Al2O3 + 3H2O

The formed Al2O3 is alumina. The alumina formed tends to be multi-phase, i.e. constituting several of the alumina phases rather than solely corundum.[5] The production process can therefore be optimized to produce a tailored product. The type of phases present affects, for example, the solubility and pore structure of the alumina product which, in turn, affects the cost of aluminium production and pollution control.[5]

Uses

Annual world production of alumina is approximately 45 million tonnes, over 90% of which is used in the manufacture of aluminium metal.[3]. The major uses of speciality aluminium oxides are in refractories, ceramics, and polishing and abrasive applications. Large tonnages are also used in the manufacture of zeolites, coating titania pigments, and as a fire retardant/smoke suppressant.

Alumina is a medium for chemical chromatography, available in basic (pH 9.5), acidic (pH 4.5 when in water) and neutral formulations.

In lighting, GE developed "Lucalox" in 1961, a transparent alumina used in sodium vapor lamps. Aluminium oxide is also used in preparation of coating suspensions in compact fluorescent lamps.

Health and medical applications include it as a material in hip replacements.[3] It is used in water filters (derived water treatment chemicals such as aluminium sulfate, aluminium chlorohydrate and sodium aluminate, are one of the few methods available to filter water-soluble fluorides out of water). It is also used in toothpaste formulations.

Aluminium oxide is used for its hardness and strength. Most pre-finished wood flooring now uses aluminium oxide as a hard protective coating. In 2004 3M developed a technique for making a ceramic composed of aluminium oxide and rare earth elements to produce a strong glass called transparent alumina. Alumina can be grown as a coating on aluminium by anodising or by plasma electrolytic oxidation (see the "Properties" section, above). Both its strength and abrasive characteristics are due to aluminium oxide's great hardness (position 9 on the Mohs scale of mineral hardness).

It is widely used as a coarse or fine abrasive, including as a much less expensive substitute for industrial diamond. Many types of sandpaper use aluminium oxide crystals. In addition, its low heat retention and low specific heat make it widely used in grinding operations, particularly cutoff tools. As the powdery abrasive mineral aloxite, it is a major component, along with silica, of the cue tip "chalk" used in billiards. Aluminium oxide powder is used in some CD/DVD polishing and scratch-repair kits. Its polishing qualities are also behind its use in toothpaste.

Aluminium oxide is widely used in the fabrication of superconducting devices, particularly single electron transistors and superconducting quantum interference devices (SQUID), where it is used to form highly resistive quantum tunnelling barriers.

See also

- Bayer process

- List of Alumina Refineries

- Transparent aluminium

References

- ↑ Mallinckrodt Baker, MSDS. "Aluminum Oxide: Material Safety Data Sheet (A28440)".

- ↑ "Aloxite", ChemIndustry.com database, retrieved 24 February 2007

- ↑ 3.0 3.1 3.2 3.3 3.4 "Alumina (Aluminium Oxide) – The Different Types of Commercially Available Grades". The A to Z of Materials. Retrieved on 2007-10-27.

- ↑ "EPCRA Section 313 Chemical List For Reporting Year 2006". US EPA. Retrieved on 2008-9-30.

- ↑ 5.0 5.1 5.2 G. Paglia, Determination of the Structure of g-Alumina using Empirical and First Principles Calculations Combined with Supporting Experiments, Curtin University of Technology, Perth, 2004, available online, p. 6

- ↑ Egon Wiberg, Arnold Frederick Holleman (2001) Inorganic Chemistry, Elsevier ISBN 0123526515